Question: no need to explain answer Question 16 What is the best definition of a value added operation? A. An operation that somehow checks the product

no need to explain answer

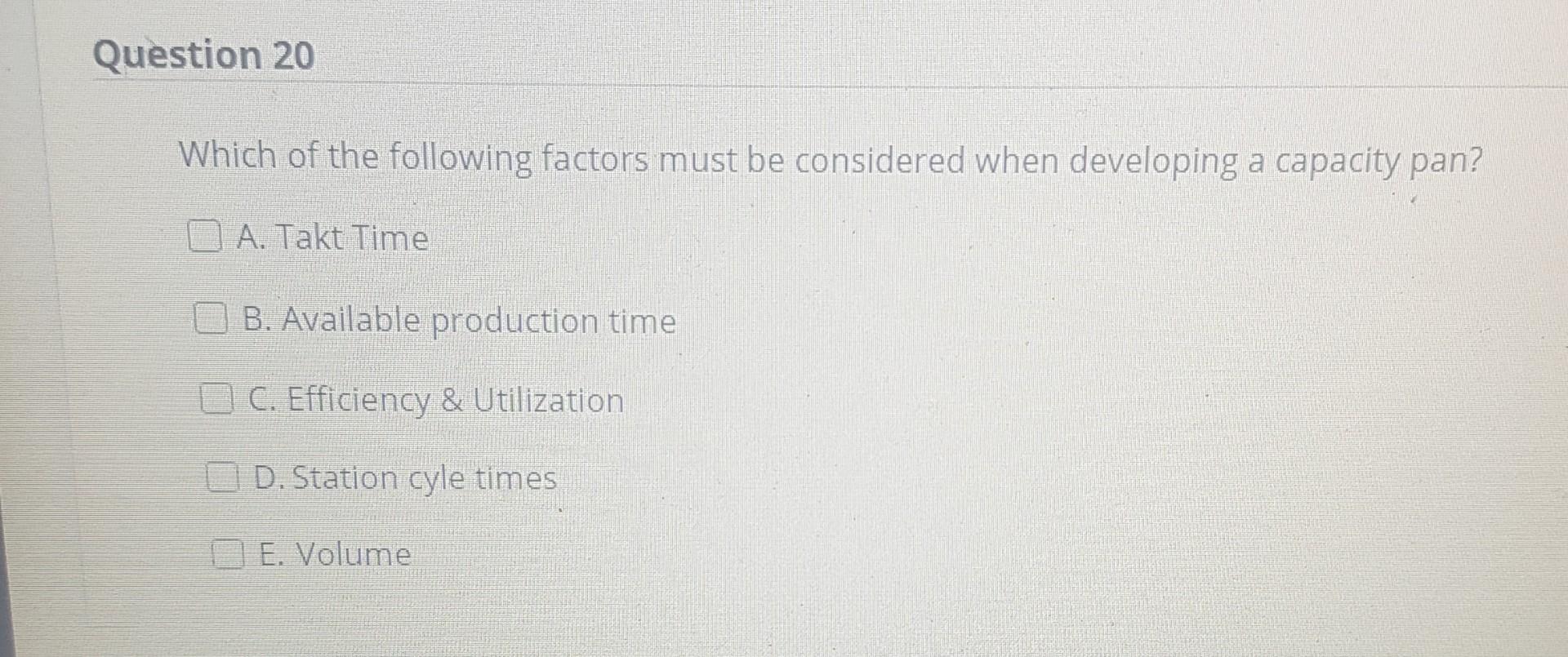

Question 16 What is the best definition of a "value added operation"? A. An operation that somehow checks the product B. An operation that the customer is willing to pay for C. An operation that changes the form of the product D. An operation required for process control E. An operation required to move the product from point A to point B Question 17 Which statement best describes "common cause variation"? O A. Variation that occurs daily O B. Variation that can be isolated and eliminated OC. Variability that is not part of the process 0 D. Process variation that cannot be removed. E. Variation that is not generic to the process Question 18 Which statement does not apply to 6-sigma quality programs? O A. 6-sigma quality programs are used worldwide OB. SPC is a key part of 6-sigma programs O C.6-sigma quality programs have a target of "Zero" defects OD. 6-sigma is a measure of process dispersion E. 6-sigma quality programs use a target of 3.4 DPM Question 19 When comparing an "In-line Layout" to a "Cellular Layout", what are the main advantages of the "In-line Layout"? A. Cycle time B. Equipment cost O C. None of the above D. Flexibility E. Labour costs Question 20 Which of the following factors must be considered when developing a capacity pan? E A. Takt Time B. Available production time E C. Efficiency & Utilization D. Station cyle times E. VolumeStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock