Question: Note: As asterisk denotes problems for which an Excel spreadsheet template at OM Online may be used. 1. Alpha Medical Manufacturing (AMM), located in Punta

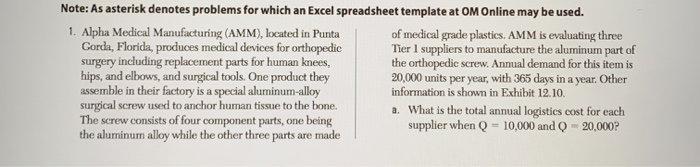

Note: As asterisk denotes problems for which an Excel spreadsheet template at OM Online may be used. 1. Alpha Medical Manufacturing (AMM), located in Punta of medical grade plastics. AMM is evaluating three Gorda, Florida, produces medical devices for orthopedic Tier 1 suppliers to manufacture the aluminum part of surgery including replacement parts for human knees, the orthopedic screw. Annual demand for this item is hips, and elbows, and surgical tools. One product they 20,000 units per year, with 365 days in a year. Other assemble in their factory is a special aluminum-alloy information is shown in Exhibit 12.10. surgical screw used to anchor human tissue to the bone. a. What is the total annual logistics cost for each The screw consists of four component parts, one being supplier when Q = 10,000 and Q -- 20,000? the aluminum alloy while the other three parts are made b. What supplier and order quantity do you recommend based on these total costs? c. List other criteria you might use to make the final supplier decision, and suggest metrics for measuring each criteria. Note: As asterisk denotes problems for which an Excel spreadsheet template at OM Online may be used. 1. Alpha Medical Manufacturing (AMM), located in Punta of medical grade plastics. AMM is evaluating three Gorda, Florida, produces medical devices for orthopedic Tier 1 suppliers to manufacture the aluminum part of surgery including replacement parts for human knees, the orthopedic screw. Annual demand for this item is hips, and elbows, and surgical tools. One product they 20,000 units per year, with 365 days in a year. Other assemble in their factory is a special aluminum-alloy information is shown in Exhibit 12.10. surgical screw used to anchor human tissue to the bone. a. What is the total annual logistics cost for each The screw consists of four component parts, one being supplier when Q = 10,000 and Q -- 20,000? the aluminum alloy while the other three parts are made b. What supplier and order quantity do you recommend based on these total costs? c. List other criteria you might use to make the final supplier decision, and suggest metrics for measuring each criteria