Question: note: handwritten not accepted please give answer in typed form. CoursHeroTranscribedText Table 2. Number of load per week Department Assembly Painting Machine Receiving Shipping Testing

note: handwritten not accepted please give answer in typed form.

CoursHeroTranscribedText

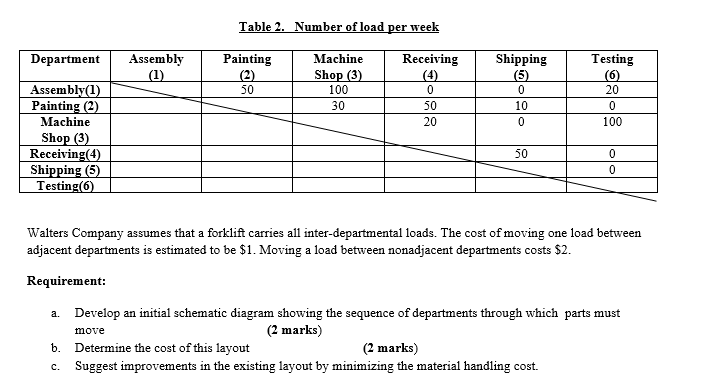

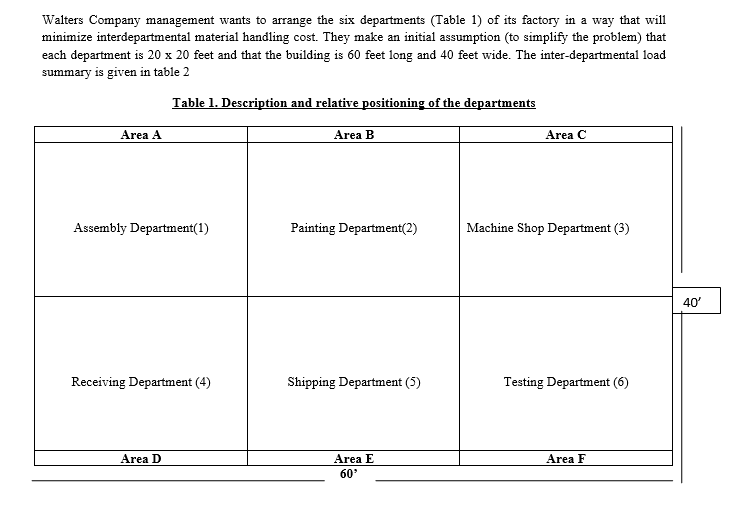

Table 2. Number of load per week Department Assembly Painting Machine Receiving Shipping Testing (1) (2) Shop (3) (4) (5) (6) Assembly(1) 50 100 0 0 20 Painting (2) Machine 30 50 10 0 20 0 100 Shop (3) Receiving(4) Shipping (5) Testing(6) 50 0 0 Walters Company assumes that a forklift carries all inter-departmental loads. The cost of moving one load between adjacent departments is estimated to be $1. Moving a load between nonadjacent departments costs $2. Requirement: a. Develop an initial schematic diagram showing the sequence of departments through which parts must move (2 marks) b. Determine the cost of this layout (2 marks) c. Suggest improvements in the existing layout by minimizing the material handling cost.

Step by Step Solution

There are 3 Steps involved in it

We have a manufacturing facility with six departments Assembly Painting Machine Shop Receiving Shipping and Testing Were given a table showing the number of loads moved between each pair of departments per week Moving a load between adjacent departments costs 1 and between nonadjacent departments costs 2 Requirement a Develop an initial schematic diagram showing the sequence of departments Since the problem doesnt specify a particular layout well assume the departments are arranged in the order they are listed in the table 1 Assembly 2 Painting 3 Machine Shop 4 Receiving 5 Shipping 6 Testing This is a linear layout Requirement b Determine the cost of this layout Lets calculate the cost by analyzing each movement and its associated cost Assembly to Painting 50 loads 1 adjacent 50 Assembly to Machine Shop 100 loads 2 nonadjacent 200 Assembly to Testing 20 loads 2 nonadjacent 40 Painting to Machine Shop 30 loads 1 adjacent 30 Painting to Receiving 50 loads 2 nonadjacent 100 Painting to Shipping 10 loads 2 nonadjacent 20 Machine Shop to Receiving 20 loads 1 adjacent 20 Machine Shop to Testing 100 loads 2 nonadjacent 200 Receiving to Shipping 50 loads 1 adjacent 50 Total Cost 50 200 40 30 100 20 20 200 50 710 Requirement c Suggest improvements in the existing layout by minimizing the material handling cost To minimize the cost we should try to arrange departments with high load movement closer together Heres a suggested approach Identify HighVolume Movements Assembly to Machine Shop 100 loads Machine Shop to Testing 100 loads Painting to Receiving 50 loads Receiving to Shipping 50 loads Rearrange Departments Assembly and Machine Shop should be adjacent Machine Shop and Testing should be adjacent Painting and Receiving should be adjacent Receiving and Shipping should be adjacent Possible Improved Layout Assembly Machine Shop Testing Painting Receiving Shipping Lets calculate the cost of this improved layout Assembly to Machine Shop 100 loads 1 adjacent 100 Assembly to Testing 20 loads 2 nonadjacent 40 Painting to Machine Shop 30 loads 2 nonadjacent 60 Painting to Receiving 50 loads 1 adjacent 50 Painting to Shipping 10 loads 1 adjacent 10 Machine Shop to Receiving 20 loads 2 nonadjacent 40 Machine Shop to Testing 100 loads 1 adjacent 100 Receiving to Shipping 50 loads 1 adjacent 50 Total Cost Improved Layout 100 40 60 50 10 40 100 50 450 Conclusion Initial Layout Cost 710 Improved Layout Cost 450 Departments We have six departments Assembly 1 Painting 2 Machine Shop 3 Receiving 4 Shipping 5 and Testing 6 Building Dimensions The building is 60 feet long and 40 feet wide Department Size Each department ... View full answer

Get step-by-step solutions from verified subject matter experts