Question: Note: If you would like to use Excel for this problem, please do so. If you choose this option, please make sure to submit an

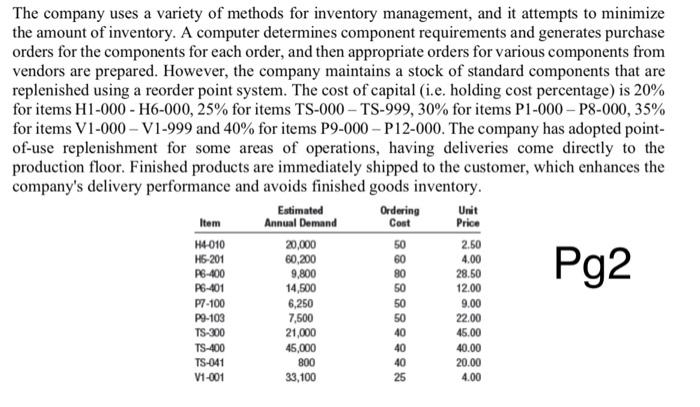

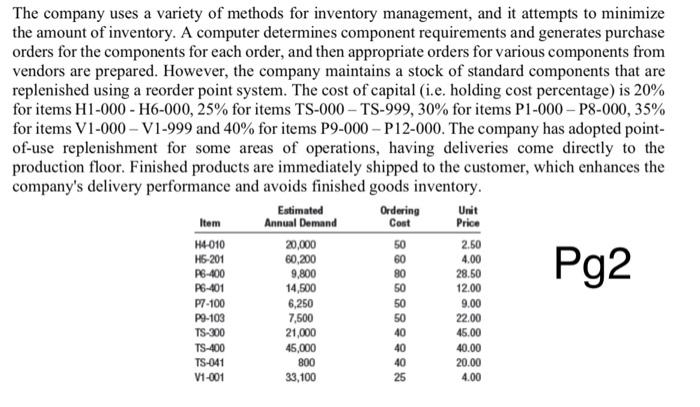

Note: If you would like to use Excel for this problem, please do so. If you choose this option, please make sure to submit an Excel file so I can still see your formulas and still place your answers in the Word document as well. Pg#1 PSC designs and produces a variety of laser bar code scanning devices. The products include handheld bar code readers, high-speed fixed-position industrial scanners, and retail checkout scanners as well as a full line of accessories, software, and supplies to support its products. Headquartered in Eugene, Oregon, the company has manufacturing facilities in Eugene and Paris, France, with roughly 1,200 employees worldwide. Bar code scanners are designed for a variety of situations that can involve long-range scanning, reading small bar codes, and performing high-speed scans. They are used extensively in industry, business, and government to manage and control the entire supply chain, which includes suppliers, production, warehousing, distribution, retail sales, and service. Examples of bar code readers include the familiar point-of-sale scanners encountered at supermarkets and other retail stores. They come in a variety of forms, ranging from handheld to built-in models. High-speed, unattended scanners are used for automated material handling and sorting. Typical installations include high-volume distribution centers such as JC Penney's catalog operation and airport baggage handling systems. Use of bar code readers has greatly increased the speed and accuracy of data collection, resulting in increased productivity, improved production and inventory tracking and control, and improved market information. The company uses a variety of methods for inventory management, and it attempts to minimize the amount of inventory. A computer determines component requirements and generates purchase orders for the components for each order, and then appropriate orders for various components from vendors are prepared. However, the company maintains a stock of standard components that are replenished using a reorder point system. The cost of capital (i.e. holding cost percentage) is 20% for items H1-000 - H6-000, 25% for items TS-000 - TS-999, 30% for items P1-000 - P8-000, 35% for items V1-000 - V1-999 and 40% for items P9-000 - P12-000. The company has adopted point- of-use replenishment for some areas of operations, having deliveries come directly to the production floor. Finished products are immediately shipped to the customer, which enhances the company's delivery performance and avoids finished goods inventory. Estimated Ordering Unit Item Annual Demand Cost H4-010 20,000 50 H5-201 60,200 P6-400 9,800 80 P6-401 14,500 50 P7-100 6,250 50 9.00 P9-108 7,500 22.00 TS-300 21,000 45,000 TS-041 40 33,100 Price 60 2.50 4.00 28.50 12.00 Pg2 40 40 TS-400 45.00 40.00 20.00 4.00 800 V1-001 25 Using the data above and the information from the case, please do the following: 1.) Perform an ABC Inventory classification analysis on the system above. The company has set the following policy for classification: A items should represent between 70-73% of the annual dollar value; B items should represent between 16 - 18% of the annual dollar value; C items should represent 9-12% of the annual dollar value. (Round your percentages the 2 decimal places). Pg3 2.) Determine the EOQ (using the basic EOQ model) for each item (Round your answers the nearest whole unit). 3.) Using your answers from #1 and #2, please explain how the company should go about managing its inventory (i.e. which inventory should be tracked more, ordered more, counted more, prioritize, and etc.)