Question: NOTE: Send the solution in computer script. Do not send by hand! Q4. ABC Clothing Company is the largest supplier of suits for W Company.

NOTE: Send the solution in computer script. Do not send by hand!

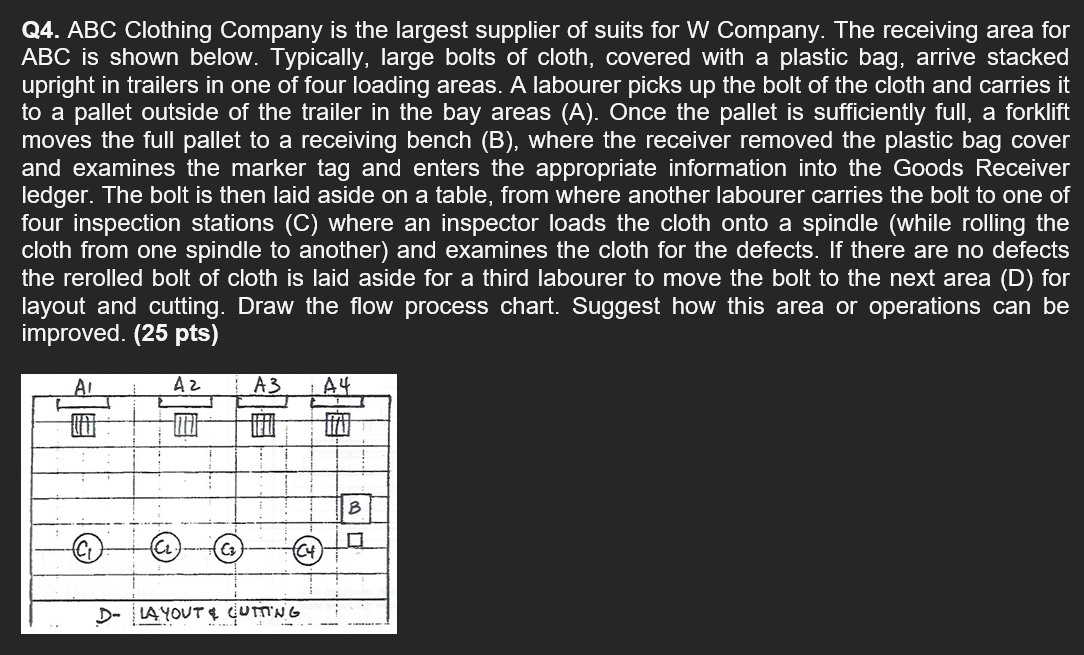

Q4. ABC Clothing Company is the largest supplier of suits for W Company. The receiving area for ABC is shown below. Typically, large bolts of cloth, covered with a plastic bag, arrive stacked upright in trailers in one of four loading areas. A labourer picks up the bolt of the cloth and carries it to a pallet outside of the trailer in the bay areas (A). Once the pallet is sufficiently full, a forklift moves the full pallet to a receiving bench (B), where the receiver removed the plastic bag cover and examines the marker tag and enters the appropriate information into the Goods Receiver ledger. The bolt is then laid aside on a table, from where another labourer carries the bolt to one of four inspection stations (C) where an inspector loads the cloth onto a spindle (while rolling the cloth from one spindle to another) and examines the cloth for the defects. If there are no defects the rerolled bolt of cloth is laid aside for a third labourer to move the bolt to the next area (D) for layout and cutting. Draw the flow process chart. Suggest how this area or operations can be improved. (25 pts) Q4. ABC Clothing Company is the largest supplier of suits for W Company. The receiving area for ABC is shown below. Typically, large bolts of cloth, covered with a plastic bag, arrive stacked upright in trailers in one of four loading areas. A labourer picks up the bolt of the cloth and carries it to a pallet outside of the trailer in the bay areas (A). Once the pallet is sufficiently full, a forklift moves the full pallet to a receiving bench (B), where the receiver removed the plastic bag cover and examines the marker tag and enters the appropriate information into the Goods Receiver ledger. The bolt is then laid aside on a table, from where another labourer carries the bolt to one of four inspection stations (C) where an inspector loads the cloth onto a spindle (while rolling the cloth from one spindle to another) and examines the cloth for the defects. If there are no defects the rerolled bolt of cloth is laid aside for a third labourer to move the bolt to the next area (D) for layout and cutting. Draw the flow process chart. Suggest how this area or operations can be improved. (25 pts)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts