Question: Now, it is time to schedule the second task. Task C has a sew time of 1.5 hrs, so it should be scheduled next. Sew

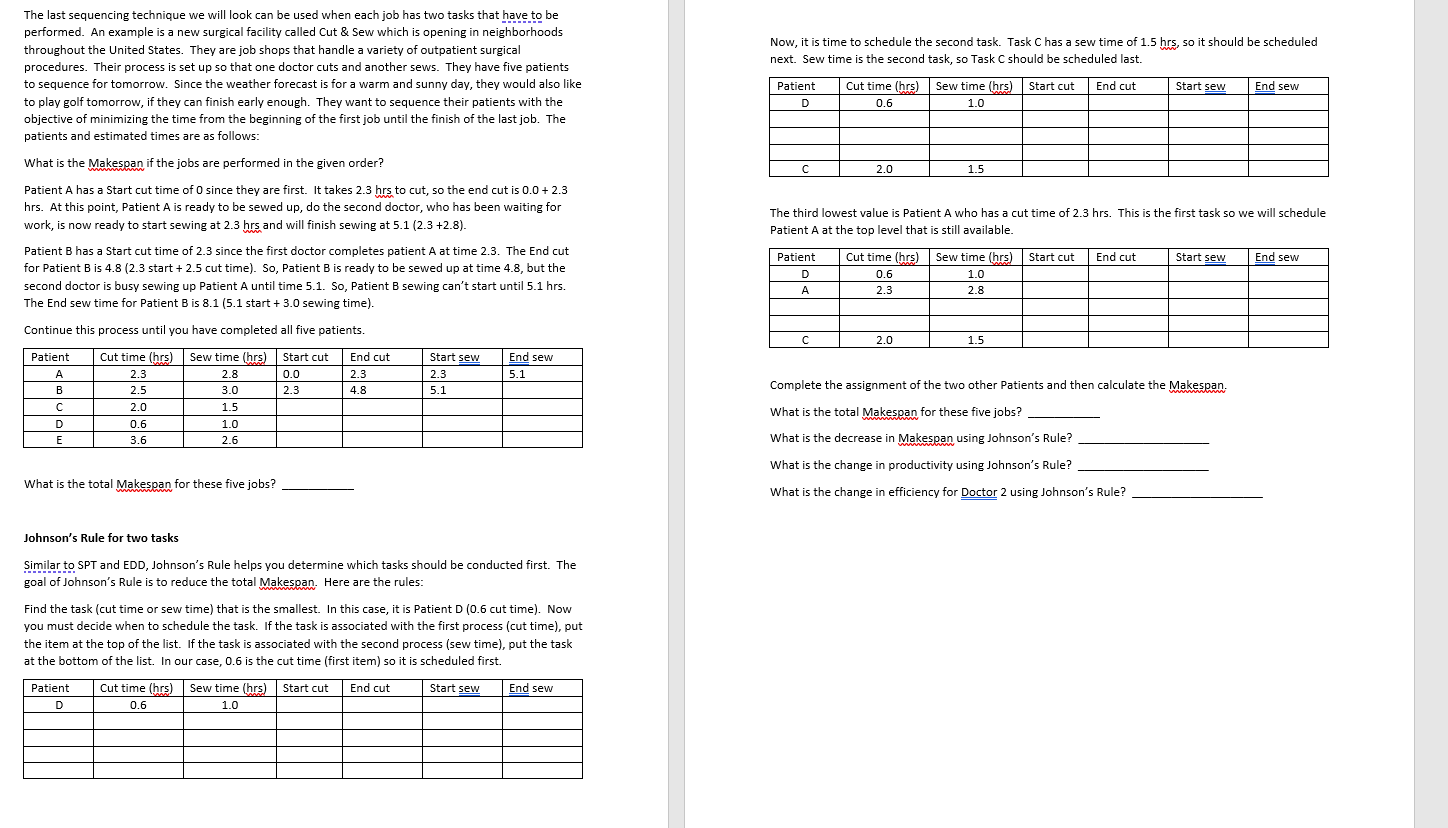

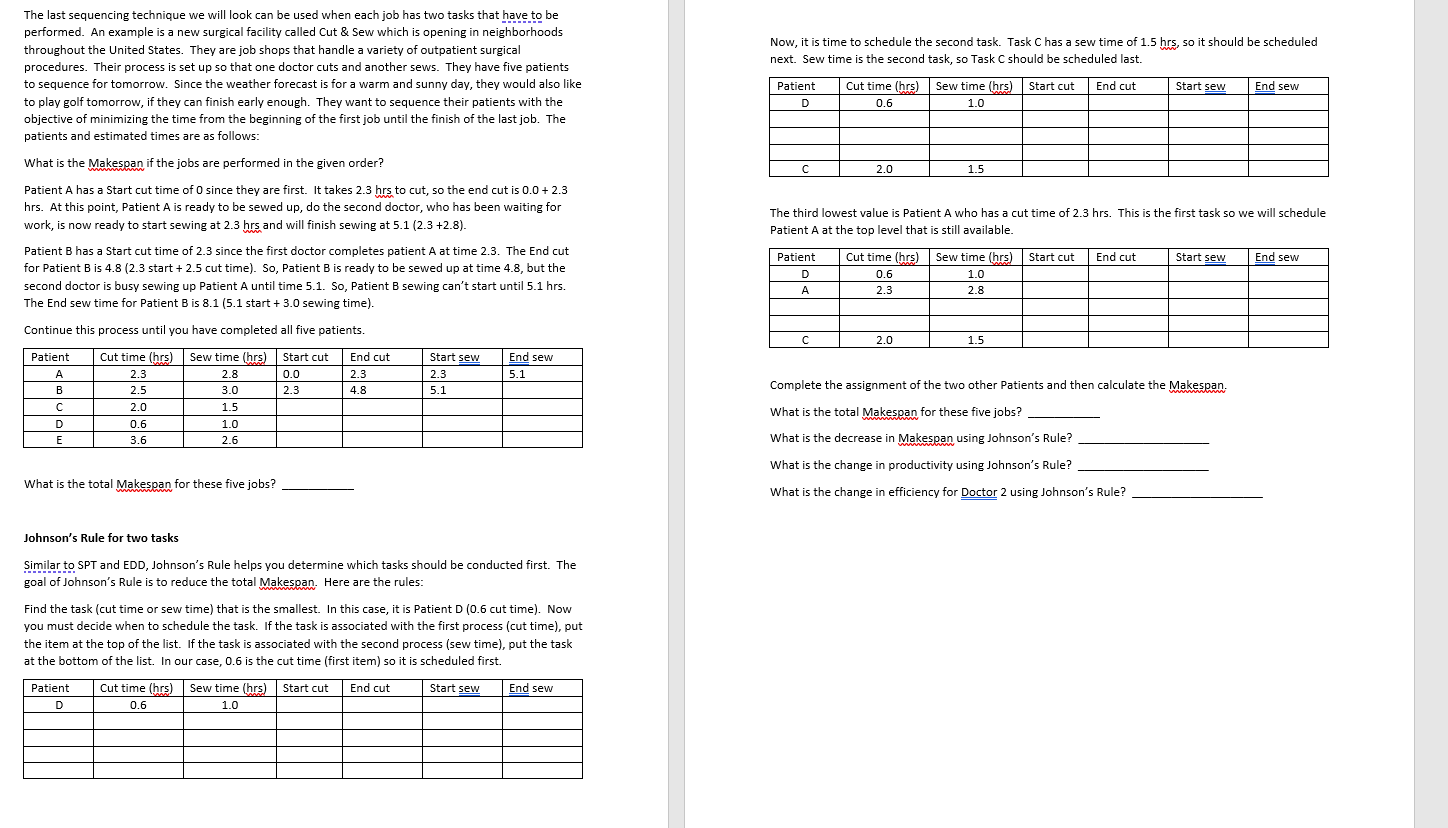

Now, it is time to schedule the second task. Task C has a sew time of 1.5 hrs, so it should be scheduled next. Sew time is the second task, so Task C should be scheduled last. The last sequencing technique we will look can be used when each job has two tasks that have to be performed. An example is a new surgical facility called Cut & Sew which is opening in neighborhoods throughout the United States. They are job shops that handle a variety of outpatient surgical procedures. Their process is set up so that one doctor cuts and another sews. They have five patients to sequence for tomorrow. Since the weather forecast is for a warm and sunny day, they would also like to play golf tomorrow, if they can finish early enough. They want to sequence their patients with the objective of minimizing the time from the beginning of the first job until the finish of the last job. The patients and estimated times are as follows: What is the Makespan if the jobs are performed in the given order? Start cut End cut Start sew End sew Patient D Cut time (hrs) Sew time (hrs) 0.6 1.0 2.0 1.5 The third lowest value is Patient A who has a cut time of 2.3 hrs. This is the first task so we will schedule Patient A at the top level that is still available. Patient A has a Start cut time of O since they are first. It takes 2.3 hrs to cut, so the end cut is 0.0 + 2.3 hrs. At this point, Patient A is ready to be sewed up, do the second doctor, who has been waiting for work, is now ready to start sewing at 2.3 hrs and will finish sewing at 5.1 (2.3 +2.8). Patient B has a Start cut time of 2.3 since the first doctor completes patient A at time 2.3. The End cut for Patient B is 4.8 (2.3 start + 2.5 cut time). So, Patient B is ready to be sewed up at time 4.8, but the second doctor is busy sewing up Patient A until time 5.1. So, Patient B sewing can't start until 5.1 hrs. The End sew time for Patient B is 8.1 (5.1 start + 3.0 sewing time). Start cut End cut Start sew End sew Patient D A Cut time (hrs) 0.6 2.3 Sew time (hrs) 1.0 2.8 Continue this process until you have completed all five patients. 2.0 1.5 Start cut 0.0 2.3 End cut 2.3 4.8 Start sew 2.3 5.1 End sew 5.1 Complete the assignment of the two other Patients and then calculate the Makespan. Patient A B C D E Cut time (hrs) 2.3 2.5 2.0 0.6 3.6 Sew time (hrs) 2.8 3.0 1.5 1.0 2.6 What is the total Makespan for these five jobs? What is the decrease in Makespan using Johnson's Rule? What is the change in productivity using Johnson's Rule? What is the change in efficiency for Doctor 2 using Johnson's Rule? What is the total Makespan for these five jobs? Johnson's Rule for two tasks Similar to SPT and EDD, Johnson's Rule helps you determine which tasks should be conducted first. The goal of Johnson's Rule is to reduce the total Makespan. Here are the rules: Find the task (cut time or sew time) that is the smallest. In this case, it is Patient D (0.6 cut time). Now you must decide when to schedule the task. If the task is associated with the first process (cut time), put the item at the top of the list. If the task is associated with the second process (sew time), put the task at the bottom of the list. In our case, 0.6 is the cut time (first item) so it is scheduled first. Start cut End cut Start sew End sew Patient D Cut time (hrs) 0.6 Sew time hrs) 1.0