Question: Old MathJax webview Only give answer with correct significant digits this is the whole question I have Support Processes A support process provides vital resources

Old MathJax webview

Only give answer with correct significant digits

this is the whole question I have

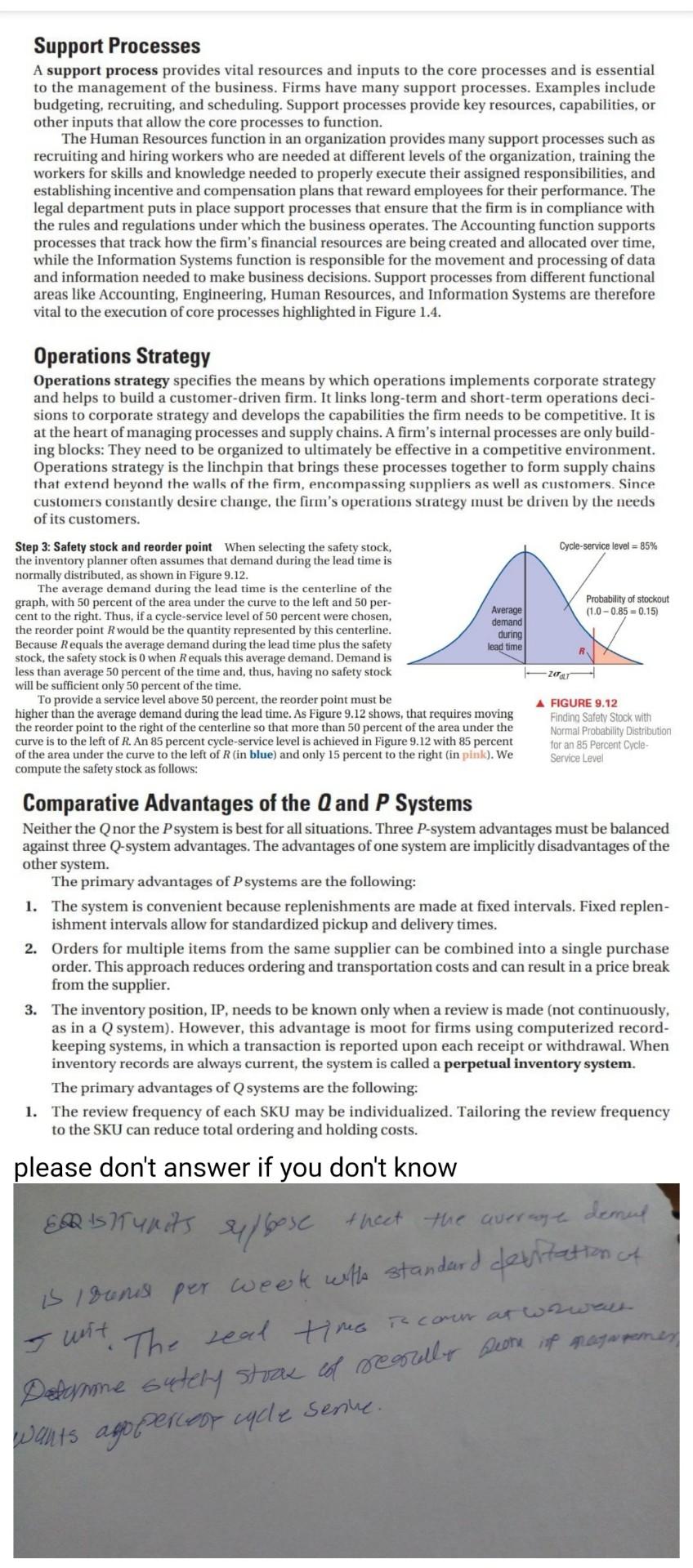

Support Processes A support process provides vital resources and inputs to the core processes and is essential to the management of the business. Firms have many support processes. Examples include budgeting, recruiting, and scheduling. Support processes provide key resources, capabilities, or other inputs that allow the core processes to function. The Human Resources function in an organization provides many support processes such as recruiting and hiring workers who are needed at different levels of the organization, training the workers for skills and knowledge needed to properly execute their assigned responsibilities, and establishing incentive and compensation plans that reward employees for their performance. The legal department puts in place support processes that ensure that the firm is in compliance with the rules and regulations under which the business operates. The Accounting function supports processes that track how the firm's financial resources are being created and allocated over time, while the Information Systems function is responsible for the movement and processing of data and information needed to make business decisions. Support processes from different functional areas like Accounting, Engineering, Human Resources, and Information Systems are therefore vital to the execution of core processes highlighted in Figure 1.4. Operations Strategy Operations strategy specifies the means by which operations implements corporate strategy and helps to build a customer-driven firm. It links long-term and short-term operations deci- sions to corporate strategy and develops the capabilities the firm needs to be competitive. It is at the heart of managing processes and supply chains. A firm's internal processes are only build- ing blocks: They need to be organized to ultimately be effective in a competitive environment. Operations strategy is the linchpin that brings these processes together to form supply chains that extend beyond the walls of the firm, encompassing suppliers as well as customers. Since customers constantly desire change, the firm's operations strategy must be driven by the needs of its customers. Step 3: Safety stock and reorder point When selecting the safety stock, Cycle-service level = 85% the inventory planner often assumes that demand during the lead time is normally distributed, as shown in Figure 9.12. The average demand during the lead time is the centerline of the Probability of stockout graph, with 50 percent of the area under the curve to the left and 50 per- Average (1.0-0.85 = 0.15) cent to the right. Thus, if a cycle-service level of 50 percent were chosen, demand the reorder point would be the quantity represented by this centerline. during Because Requals the average demand during the lead time plus the safety lead time stock, the safety stock is when Requals this average demand. Demand is less than average 50 percent of the time and, thus, having no safety stock ZOLT will be sufficient only 50 percent of the time. To provide a service level above 50 percent, the reorder point must be A FIGURE 9.12 higher than the average demand during the lead time. As gure 9.12 shows, that requires moving Finding Safety Stock with the reorder point to the right of the centerline so that more than 50 percent of the area under the Normal Probability Distribution curve is to the left of R. An 85 percent cycle-service level is achieved in Figure 9.12 with 85 percent for an 85 Percent Cycle of the area under the curve to the left of R (in blue) and only 15 percent to the right in pink). We Service Level compute the safety stock as follows: Comparative Advantages of the Q and P Systems Neither the Qnor the P system is best for all situations. Three P-system advantages must be balanced against three Q-system advantages. The advantages of one system are implicitly disadvantages of the other system. The primary advantages of P systems are the following: 1. The system is convenient because replenishments are made at fixed intervals. Fixed replen- ishment intervals allow for standardized pickup and delivery times. 2. Orders for multiple items from the same supplier can be combined into a single purchase order. This approach reduces ordering and transportation costs and can result in a price break from the supplier. 3. The inventory position, IP, needs to be known only when a review is made (not continuously, as in a Q system). However, this advantage is moot for firms using computerized record- keeping systems, in which a transaction is reported upon each receipt or withdrawal. When inventory records are always current, the system is called a perpetual inventory system. The primary advantages of Q systems are the following: 1. The review frequency of each SKU may be individualized. Tailoring the review frequency to the SKU can reduce total ordering and holding costs. please don't answer if you don't know Edisitunits suppose theat the average demul I wit is bonis per week wille standard desitation 4 The real time to comm at wawach Determine sutely strak en begruello Deore if nega pomen Wanys ago percent que senke

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts