Question: On page 98, Rogo's team decides to implement a release-of-materials schedule. As Bob Donovan notes, We don't want too much inventory flooding the floor, but

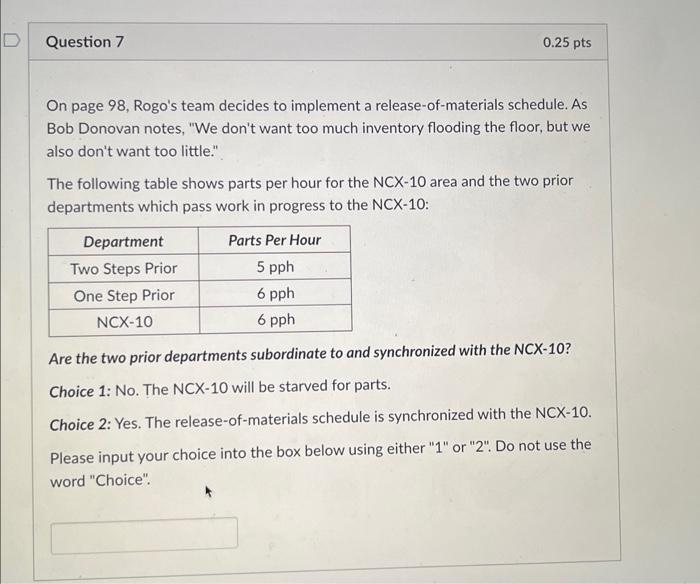

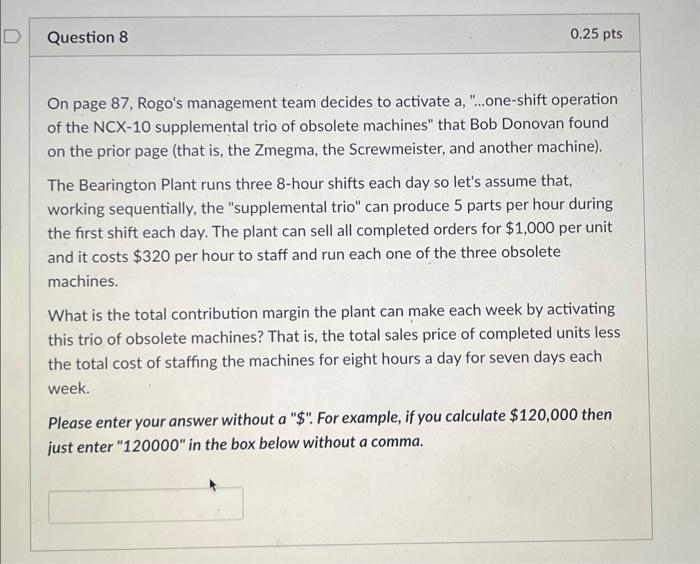

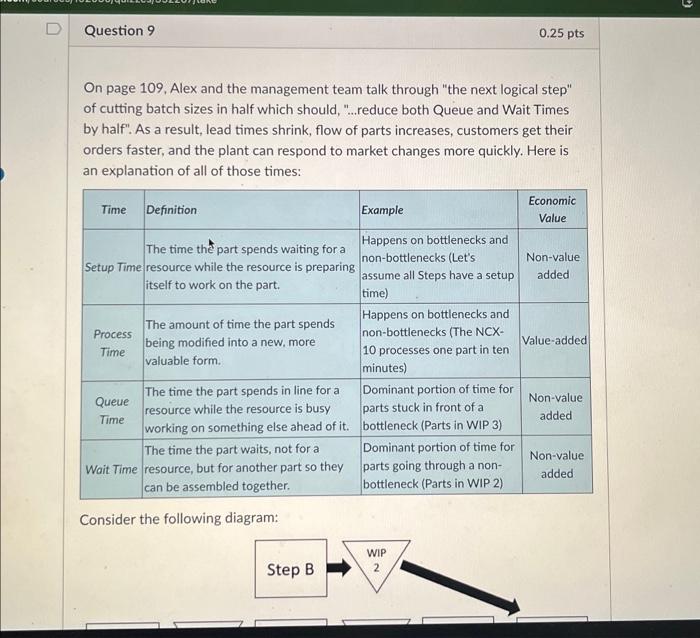

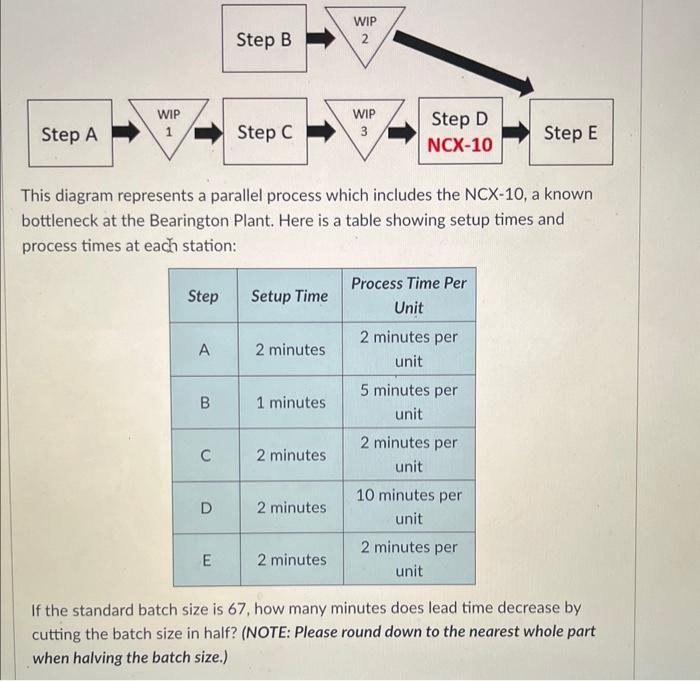

On page 98, Rogo's team decides to implement a release-of-materials schedule. As Bob Donovan notes, "We don't want too much inventory flooding the floor, but we also don't want too little." The following table shows parts per hour for the NCX-10 area and the two prior departments which pass work in progress to the NCX-10: Are the two prior departments subordinate to and synchronized with the NCX-10? Choice 1: No. The NCX-10 will be starved for parts. Choice 2: Yes. The release-of-materials schedule is synchronized with the NCX-10. Please input your choice into the box below using either " 1 " or " 2 ". Do not use the word "Choice". On page 87, Rogo's management team decides to activate a, "...one-shift operation of the NCX-10 supplemental trio of obsolete machines" that Bob Donovan found on the prior page (that is, the Zmegma, the Screwmeister, and another machine). The Bearington Plant runs three 8-hour shifts each day so let's assume that, working sequentially, the "supplemental trio" can produce 5 parts per hour during the first shift each day. The plant can sell all completed orders for $1,000 per unit and it costs $320 per hour to staff and run each one of the three obsolete machines. What is the total contribution margin the plant can make each week by activating this trio of obsolete machines? That is, the total sales price of completed units less the total cost of staffing the machines for eight hours a day for seven days each week. Please enter your answer without a "\$". For example, if you calculate $120,000 then just enter "120000" in the box below without a comma. This diagram represents a parallel process which includes the NCX-10, a known bottleneck at the Bearington Plant. Here is a table showing setup times and process times at eachi station: If the standard batch size is 67 , how many minutes does lead time decrease by cutting the batch size in half? (NOTE: Please round down to the nearest whole part when halving the batch size.) On page 109 , Alex and the management team talk through "the next logical step" of cutting batch sizes in half which should, "...reduce both Queue and Wait Times by half". As a result, lead times shrink, flow of parts increases, customers get their orders faster, and the plant can respond to market changes more quickly. Here is an explanation of all of those times: Consider the following diagram

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts