Question: Only need question e. The manager at Ormonde Inc. collected the value stream mapping data from the plant's most problematic manufacturing cell that fabricates parts

Only need question e.

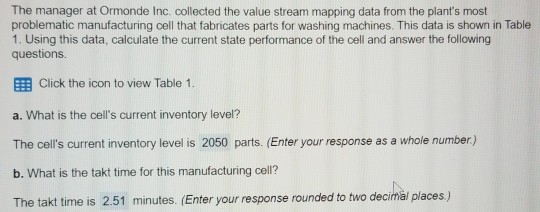

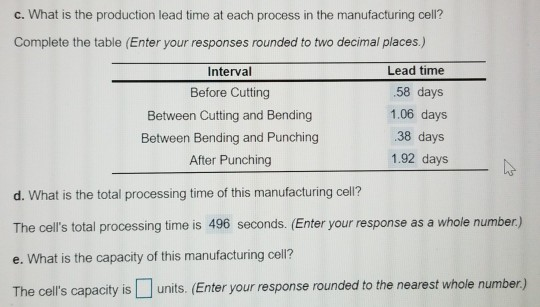

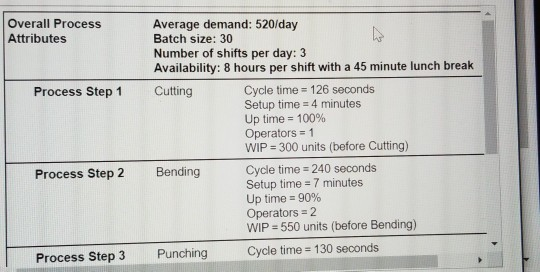

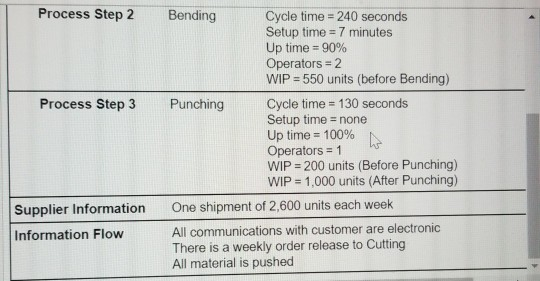

The manager at Ormonde Inc. collected the value stream mapping data from the plant's most problematic manufacturing cell that fabricates parts for washing machines. This data is shown in Table 1. Using this data, calculate the current state performance of the cell and answer the following questions. BSS Click the icon to view Table 1 a. What is the cell's current inventory level? The cell's current inventory level is 2050 parts. (Enter your response as a whole number.) b. What is the takt time for this manufacturing cell? The takt time is 2.51 minutes. (Enter your response rounded to two decimal places.) c. What is the production lead time at each process in the manufacturing cell? Complete the table (Enter your responses rounded to two decimal places.) Interval Before Cutting Between Cutting and Bending Between Bending and Punching After Punching Lead time .58 days 1.06 days 38 days 1.92 days d. What is the total processing time of this manufacturing cell? The cell's total processing time is 496 seconds. (Enter your response as a whole number.) e. What is the capacity of this manufacturing cell? The cell's capacity is units. (Enter your response rounded to the nearest whole number) Overall Process Attributes Process Step 1 Average demand: 520/day Batch size: 30 Number of shifts per day: 3 Availability: 8 hours per shift with a 45 minute lunch break Cutting Cycle time = 126 seconds Setup time = 4 minutes Up time = 100% Operators = 1 WIP = 300 units (before Cutting) Bending Cycle time = 240 seconds Setup time = 7 minutes Up time = 90% Operators = 2 WIP = 550 units (before Bending) Punching Cycle time - 130 seconds Process Step 2 Process Step 3 Process Step 2 Process Step 3 Bending Cycle time = 240 seconds Setup time = 7 minutes Up time = 90% Operators = 2 WIP = 550 units (before Bending) Punching Cycle time = 130 seconds Setup time = none Up time = 100% N Operators = 1 WIP = 200 units (Before Punching) WIP = 1,000 units (After Punching) One shipment of 2,600 units each week All communications with customer are electronic There is a weekly order release to Cutting All material is pushed Supplier Information Information FlowStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock