Question: only set problem, do not need to solve. 15. A plant purchases components that are then combined into subassemblies. The subassemblies are produced in batches

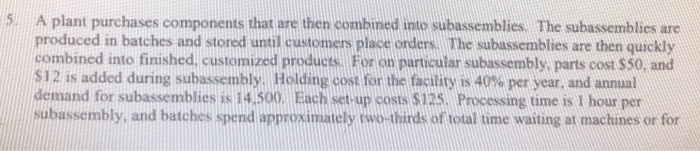

15. A plant purchases components that are then combined into subassemblies. The subassemblies are produced in batches and stored until customers place orders. The subassemblies are then quickly combined into finished, customized products For on particular subassembly, parts cost $50, and $12 is added during subassembly Holding cost for the facility is 40% per year, and annual demand for subassemblies is 14,500. Each set-up costs $125 Processing time is 1 hour per subassembly, and batches spend approximately two-thirds of total time waiting at machines or for material handling. Find the optimal batch size for making the subassemblies. Assume 2,000 hours per year (50 weeks at 40 hours/week)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts