Question: Operational Desicion Making Question Part A. (Chapter 9: Forecasting): A recent college graduate was hired by a whole foods store as an operations planner. The

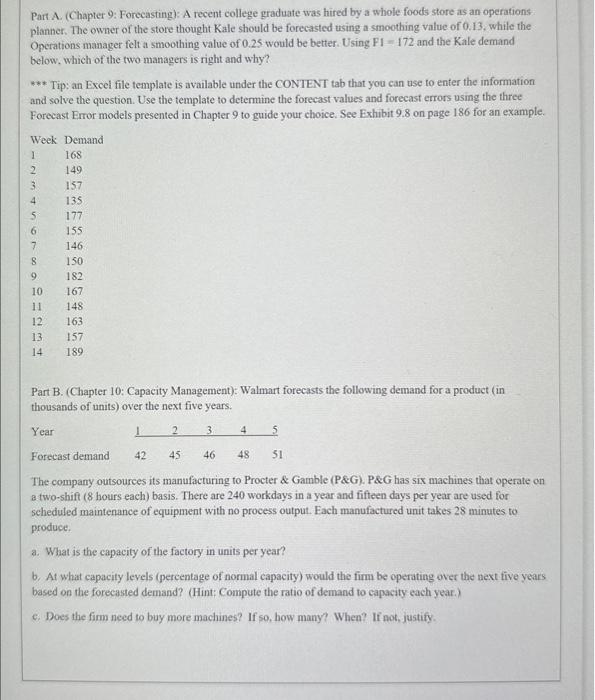

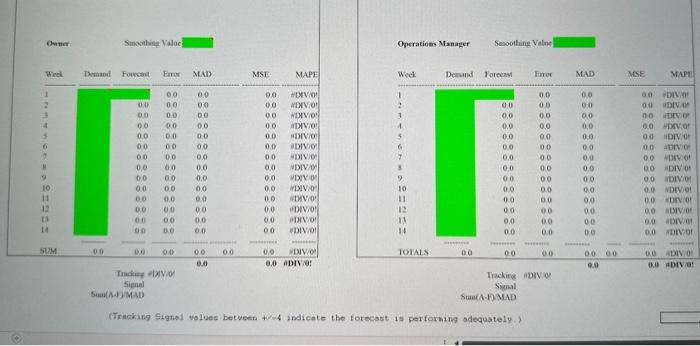

Part A. (Chapter 9: Forecasting): A recent college graduate was hired by a whole foods store as an operations planner. The owner of the store thought Kale should be forecasted using a smoothing value of 0 .13, while the Operations manager felt a smoothing value of 0.25 would be better. Using FI=172 and the Kale demand below, which of the two managers is right and why? Tip: an Excel file template is available under the CONIENT tab that you can use to enter the information and solve the question. Use the template to determine the forecast values and forecast errors using the three Forecast Error models presented in Chapter 9 to guide your choice. See Exhibit 9.8 on page 186 for an example. Part B. (Chapter 10: Capacity Management): Walmart forecasts the following demand for a product (in thousands of units) over the next five years. The company outsources its manufacturing to Procter \& Gamble (P\&G). P\&G has six machines that operate on a two-shift ( 8 hours each) basis. There are 240 workdays in a year and fifteen days per year are used for scheduled maintenance of equipment with no process output. Each manufactured unit takes 28 minutes to produce. a. What is the capacity of the factory in units per year? b. At what capacity levels (percentage of normal capacity) would the firm be operating over the next five years based on the forecasted demand? (Hint: Compute the ratio of demand to capacity each year.) e. Does the firm need to buy more machines? If so, how many? When? If not, justify. (Tracking Srgno1 volues between toe indicate the torecsst is perforaing adequately.)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts