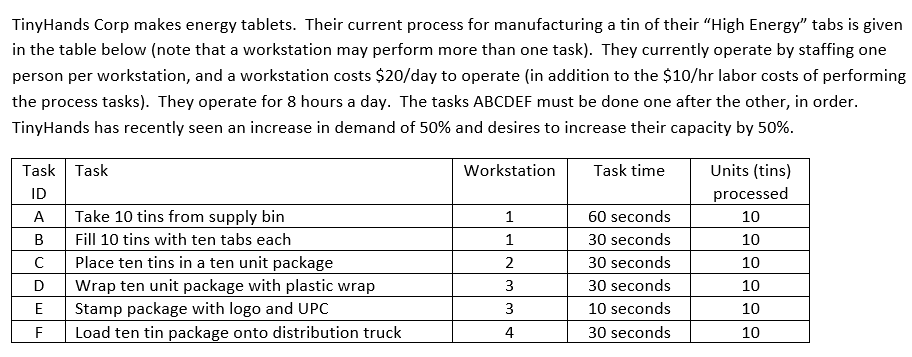

Question: Operations Management Redesign the process to increase capacity at least 50% without changing the tasks per station (ie, adding one or more stations rather than

Operations Management

- Redesign the process to increase capacity at least 50% without changing the tasks per station (ie, adding one or more stations rather than moving tasks around to different workstations) and calculate the new cycle time of the process and the new capacity of the process.

- Calculate utilization by station and in total for the process.

- Redesign the process to decrease idle time (you may use any design that maintains precedence), while still meeting the capacity increase goals of TinyHands.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock