Question: Other answers on here are wrong. Manager T. C. Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must develop an aggregate

Other answers on here are wrong.

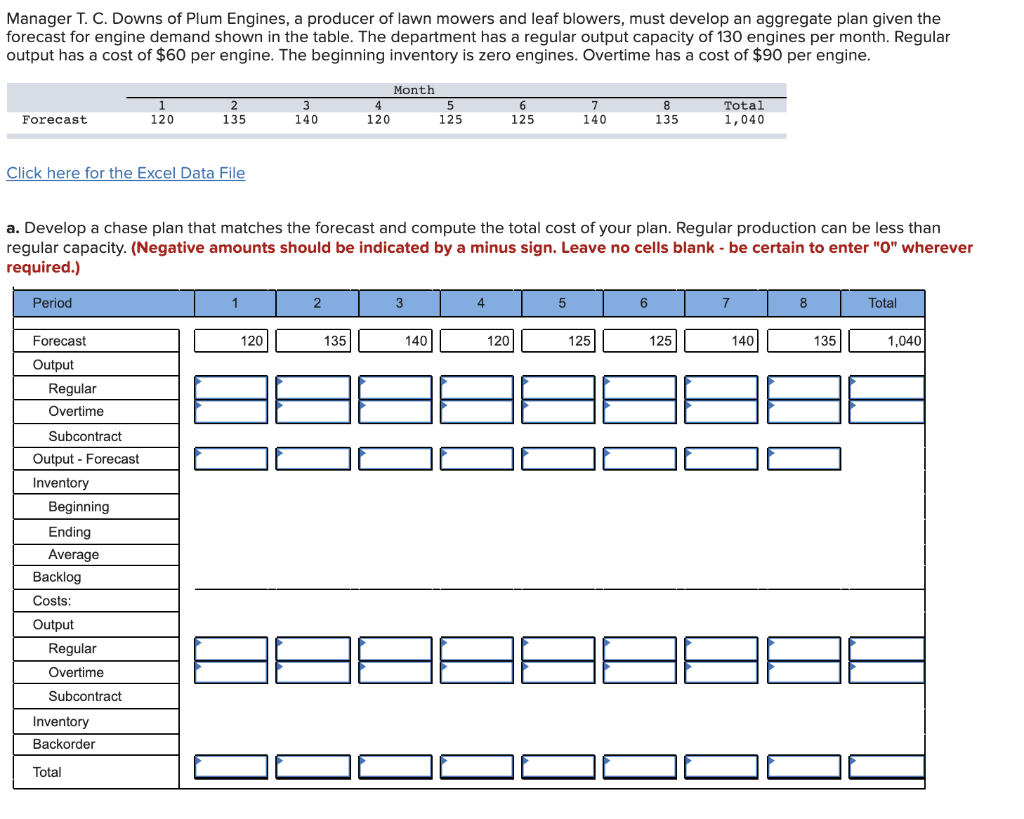

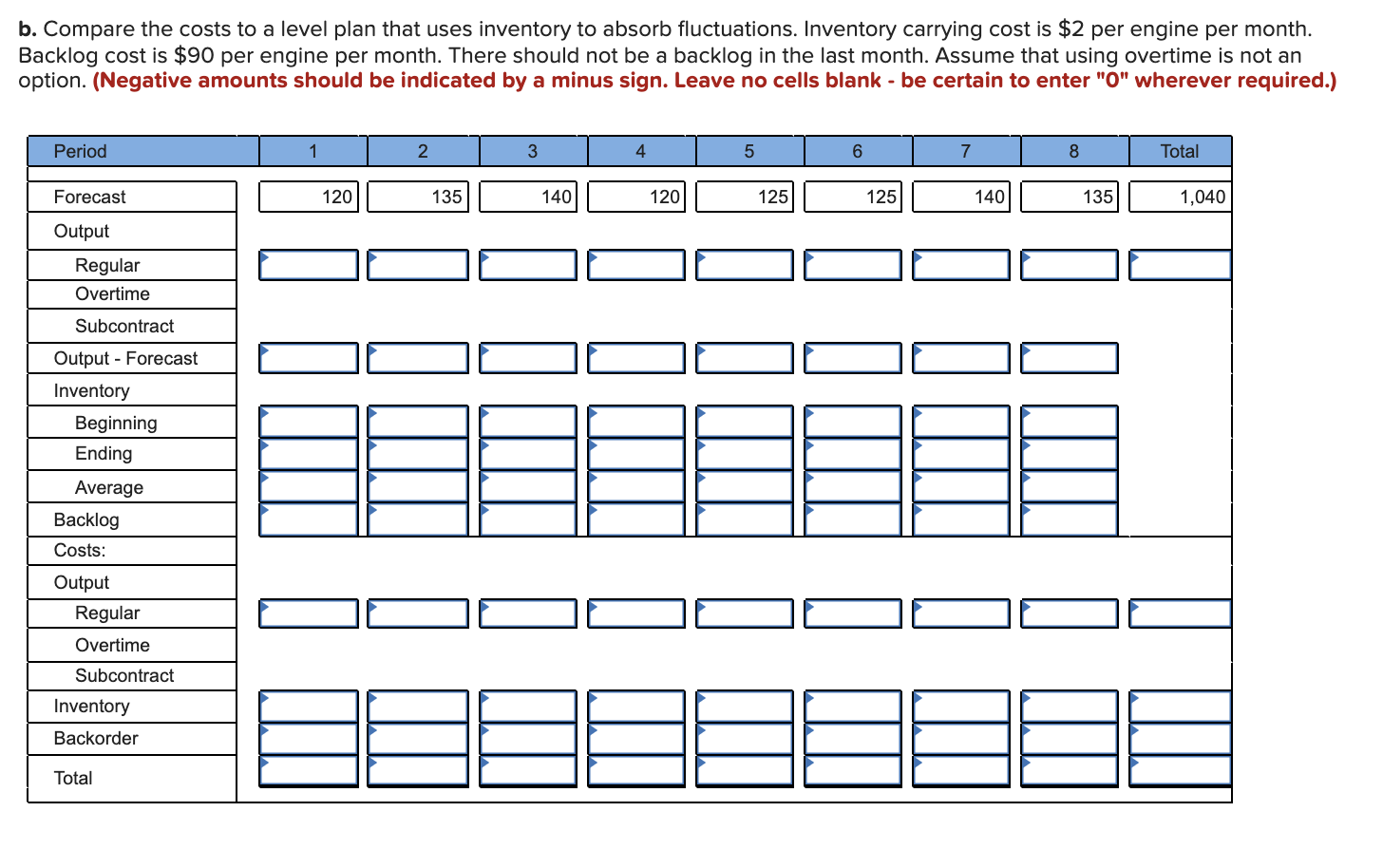

Manager T. C. Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must develop an aggregate plan given the forecast for engine demand shown in the table. The department has a regular output capacity of 130 engines per month. Regular output has a cost of $60 per engine. The beginning inventory is zero engines. Overtime has a cost of $90 per engine. Month 4 120 125 120 Forecast 135 6 125 140 8 135 140 Total 1,040 Click here for the Excel Data File a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Regular production can be less than regular capacity. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" wherever required.) Period 2. 3 4 5 6 7 8 Total 120 135 140 120 125 125 140 135 1,040 Forecast Output Regular Overtime Subcontract Output - Forecast Inventory Beginning Ending Average Backlog Costs: Output Regular Overtime Subcontract Inventory Backorder Total b. Compare the costs to a level plan that uses inventory to absorb fluctuations. Inventory carrying cost is $2 per engine per month. Backlog cost is $90 per engine per month. There should not be a backlog in the last month. Assume that using overtime is not an option. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "O" wherever required.) Period 2 3 4 5 6 7 8 Total Forecast 120 135 140 120 125 125 140 135 1,040 Output Regular Overtime Subcontract Output - Forecast Inventory Beginning Ending Average Backlog Costs: Output Regular Overtime Subcontract Inventory Backorder TotalStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock