Question: our product assembly is Laser torch OBJECTIVES: The project allows the students to learn many DFMA concepts, principles, and guidelines and enable them to evaluate

our product assembly is Laser torch

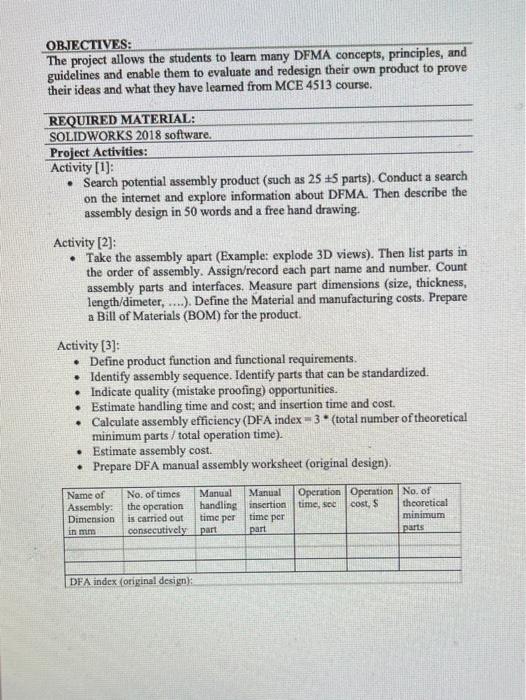

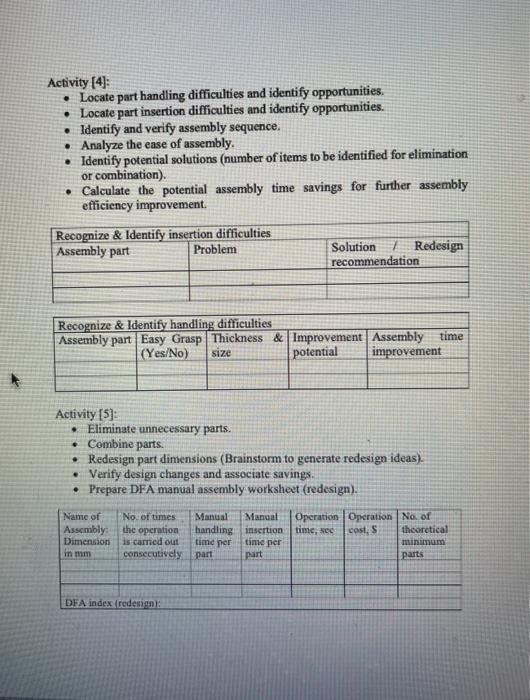

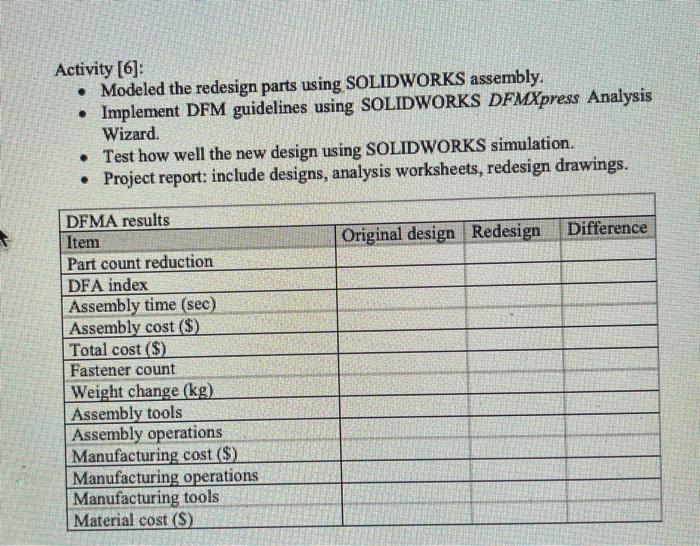

OBJECTIVES: The project allows the students to learn many DFMA concepts, principles, and guidelines and enable them to evaluate and redesign their own product to prove their ideas and what they have learned from MCE 4513 course, REQUIRED MATERIAL: SOLIDWORKS 2018 software. Project Activities: Activity (1): Search potential assembly product (such as 25 +5 parts). Conduct a search on the internet and explore information about DFMA. Then describe the assembly design in 50 words and a free hand drawing, Activity (2) Take the assembly apart (Example: explode 3D views). Then list parts in the order of assembly. Assign/record each part name and number. Count assembly parts and interfaces. Measure part dimensions (size, thickness, length/dimeter, ....). Define the Material and manufacturing costs. Prepare a Bill of Materials (BOM) for the product. Activity (3]: Define product function and functional requirements. Identify assembly sequence. Identify parts that can be standardized. Indicate quality (mistake proofing) opportunities. Estimate handling time and cost; and insertion time and cost. Calculate assembly efficiency (DFA index - 3* (total number of theoretical minimum parts/total operation time). Estimate assembly cost. Prepare DFA manual assembly worksheet (original design) Name of Assembly Dimension in mim No. of times Manual Manual Operation Operation No. of the operation handling Insertion time, sec cost, theoretical is carried out minimum consecutively part part parts time per time per DFA index (original design): Activity (4): Locate part handling difficulties and identify opportunities. Locate part insertion difficulties and identify opportunities. Identify and verify assembly sequence. Analyze the case of assembly. Identify potential solutions (number of items to be identified for elimination or combination) Calculate the potential assembly time savings for further assembly efficiency improvement. Recognize & Identify insertion difficulties Assembly part Problem Solution Redesign recommendation Recognize & Identify handling difficulties Assembly part Easy Grasp Thickness & Improvement Assembly time (Yes/No) size potential improvement Activity (5) Eliminate unnecessary parts. Combine parts Redesign part dimensions (Brainstorm to generate redesign ideas). Verify design changes and associate savings Prepare DFA manual assembly worksheet (redesign). Name of No. of times Manual Manual Operation Operation No. of Assembly the operation handling insertion time, sec theoretical Dimensioni is camned out time per minimum in mm consecutively part part parts cost, S time per DFA index redesign Activity [6]: Modeled the redesign parts using SOLIDWORKS assembly. Implement DFM guidelines using SOLIDWORKS DFMXpress Analysis Wizard. Test how well the new design using SOLIDWORKS simulation. Project report: include designs, analysis worksheets, redesign drawings. Original design Redesign Difference DFMA results Item Part count reduction DFA index Assembly time (sec) Assembly cost ($) Total cost ($) Fastener count Weight change (kg) Assembly tools Assembly operations Manufacturing cost ($) Manufacturing operations Manufacturing tools Material cost (S) Laser torch OBJECTIVES: The project allows the students to learn many DFMA concepts, principles, and guidelines and enable them to evaluate and redesign their own product to prove their ideas and what they have learned from MCE 4513 course, REQUIRED MATERIAL: SOLIDWORKS 2018 software. Project Activities: Activity (1): Search potential assembly product (such as 25 +5 parts). Conduct a search on the internet and explore information about DFMA. Then describe the assembly design in 50 words and a free hand drawing, Activity (2) Take the assembly apart (Example: explode 3D views). Then list parts in the order of assembly. Assign/record each part name and number. Count assembly parts and interfaces. Measure part dimensions (size, thickness, length/dimeter, ....). Define the Material and manufacturing costs. Prepare a Bill of Materials (BOM) for the product. Activity (3]: Define product function and functional requirements. Identify assembly sequence. Identify parts that can be standardized. Indicate quality (mistake proofing) opportunities. Estimate handling time and cost; and insertion time and cost. Calculate assembly efficiency (DFA index - 3* (total number of theoretical minimum parts/total operation time). Estimate assembly cost. Prepare DFA manual assembly worksheet (original design) Name of Assembly Dimension in mim No. of times Manual Manual Operation Operation No. of the operation handling Insertion time, sec cost, theoretical is carried out minimum consecutively part part parts time per time per DFA index (original design): Activity (4): Locate part handling difficulties and identify opportunities. Locate part insertion difficulties and identify opportunities. Identify and verify assembly sequence. Analyze the case of assembly. Identify potential solutions (number of items to be identified for elimination or combination) Calculate the potential assembly time savings for further assembly efficiency improvement. Recognize & Identify insertion difficulties Assembly part Problem Solution Redesign recommendation Recognize & Identify handling difficulties Assembly part Easy Grasp Thickness & Improvement Assembly time (Yes/No) size potential improvement Activity (5) Eliminate unnecessary parts. Combine parts Redesign part dimensions (Brainstorm to generate redesign ideas). Verify design changes and associate savings Prepare DFA manual assembly worksheet (redesign). Name of No. of times Manual Manual Operation Operation No. of Assembly the operation handling insertion time, sec theoretical Dimensioni is camned out time per minimum in mm consecutively part part parts cost, S time per DFA index redesign Activity [6]: Modeled the redesign parts using SOLIDWORKS assembly. Implement DFM guidelines using SOLIDWORKS DFMXpress Analysis Wizard. Test how well the new design using SOLIDWORKS simulation. Project report: include designs, analysis worksheets, redesign drawings. Original design Redesign Difference DFMA results Item Part count reduction DFA index Assembly time (sec) Assembly cost ($) Total cost ($) Fastener count Weight change (kg) Assembly tools Assembly operations Manufacturing cost ($) Manufacturing operations Manufacturing tools Material cost (S) Laser torch