Question: P 6 . 4 1 High - purity silicon, used in making electronic devices and solar cells, is produced from two inexpensive raw materials, sand

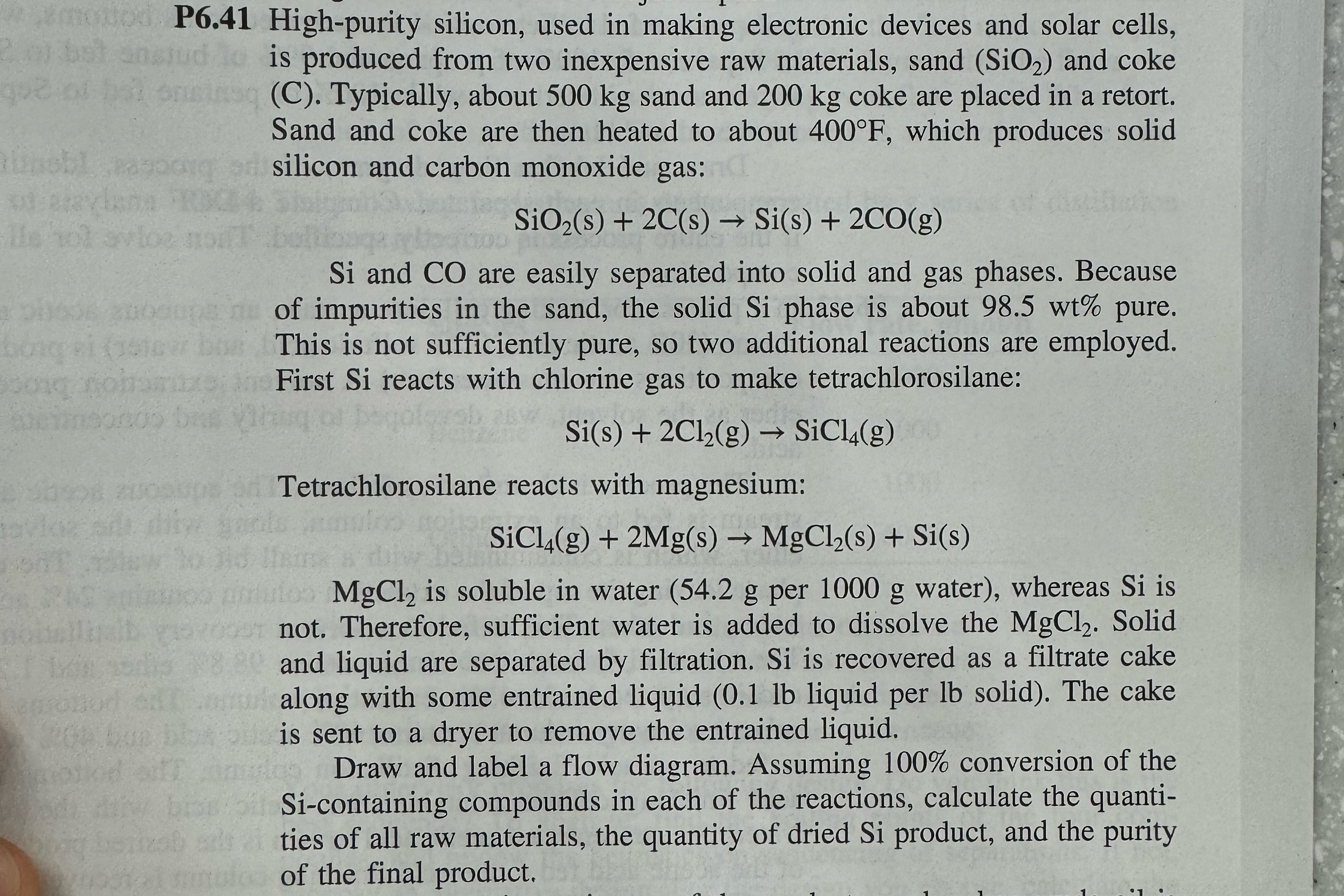

P Highpurity silicon, used in making electronic devices and solar cells, is produced from two inexpensive raw materials, sand and coke C Typically, about sand and coke are placed in a retort. Sand and coke are then heated to about which produces solid silicon and carbon monoxide gas:

and are easily separated into solid and gas phases. Because of impurities in the sand, the solid phase is about pure. This is not sufficiently pure, so two additional reactions are employed. First Si reacts with chlorine gas to make tetrachlorosilane:

Tetrachlorosilane reacts with magnesium:

is soluble in water per water whereas is not. Therefore, sufficient water is added to dissolve the Solid and liquid are separated by filtration. is recovered as a filtrate cake along with some entrained liquid liquid per solid The cake is sent to a dryer to remove the entrained liquid.

Draw and label a flow diagram. Assuming conversion of the Sicontaining compounds in each of the reactions, calculate the quantities of all raw materials, the quantity of dried Si product, and the purity of the final product.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock