Question: PART 2 : BIDS The price point the team thought made the most sense was $ 5 9 9 . To mass - produce the

PART : BIDS

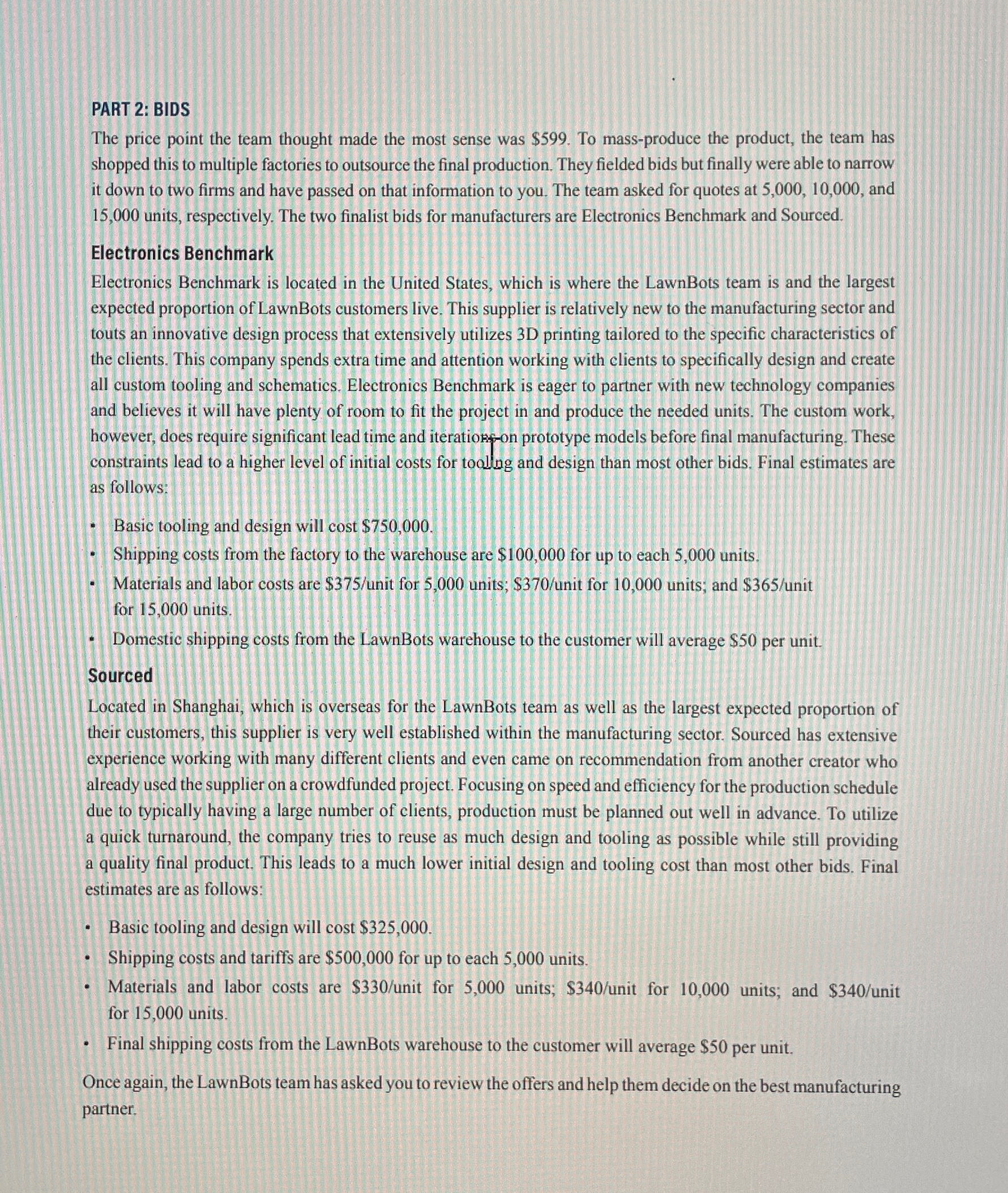

The price point the team thought made the most sense was $ To massproduce the product, the team has shopped this to multiple factories to outsource the final production. They fielded bids but finally were able to narrow it down to two firms and have passed on that information to you. The team asked for quotes at and units, respectively. The two finalist bids for manufacturers are Electronics Benchmark and Sourced.

Electronics Benchmark

Electronics Benchmark is located in the United States, which is where the LawnBots team is and the largest expected proportion of LawnBots customers live. This supplier is relatively new to the manufacturing sector and touts an innovative design process that extensively utilizes D printing tailored to the specific characteristics of the clients. This company spends extra time and attention working with clients to specifically design and create all custom tooling and schematics. Electronics Benchmark is eager to partner with new technology companies and believes it will have plenty of room to fit the project in and produce the needed units. The custom work, however, does require significant lead time and iteratiofon prototype models before final manufacturing. These constraints lead to a higher level of initial costs for toollog and design than most other bids. Final estimates are as follows:

Basic tooling and design will cost $

Shipping costs from the factory to the warehouse are $ for up to each units.

Materials and labor costs are $ unit for units; $ unit for units; and $ unit for units.

Domestic shipping costs from the LawnBots warehouse to the customer will average $ per unit.

Sourced

Located in Shanghai, which is overseas for the LawnBots team as well as the largest expected proportion of their customers, this supplier is very well established within the manufacturing sector. Sourced has extensive experience working with many different clients and even came on recommendation from another creator who already used the supplier on a crowdfunded project. Focusing on speed and efficiency for the production schedule due to typically having a large number of clients, production must be planned out well in advance. To utilize a quick turnaround, the company tries to reuse as much design and tooling as possible while still providing a quality final product. This leads to a much lower initial design and tooling cost than most other bids. Final estimates are as follows:

Basic tooling and design will cost $

Shipping costs and tariffs are $ for up to each units.

Materials and labor costs are $ unit for $ units; $ unit for units; and $ unit for units.

Final shipping costs from the LawnBots warehouse to the customer will average $ per unit.

Once again, the LawnBots team has asked you to review the offers and help them decide on the best manufacturing partner.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock