Question: Part 2: Flow Systems, Activity Relationships, and Space Requirements Problem 1: A factory has four planning departments (1,2,3,4). Product A is manufactured in sequence 1-2-3-4

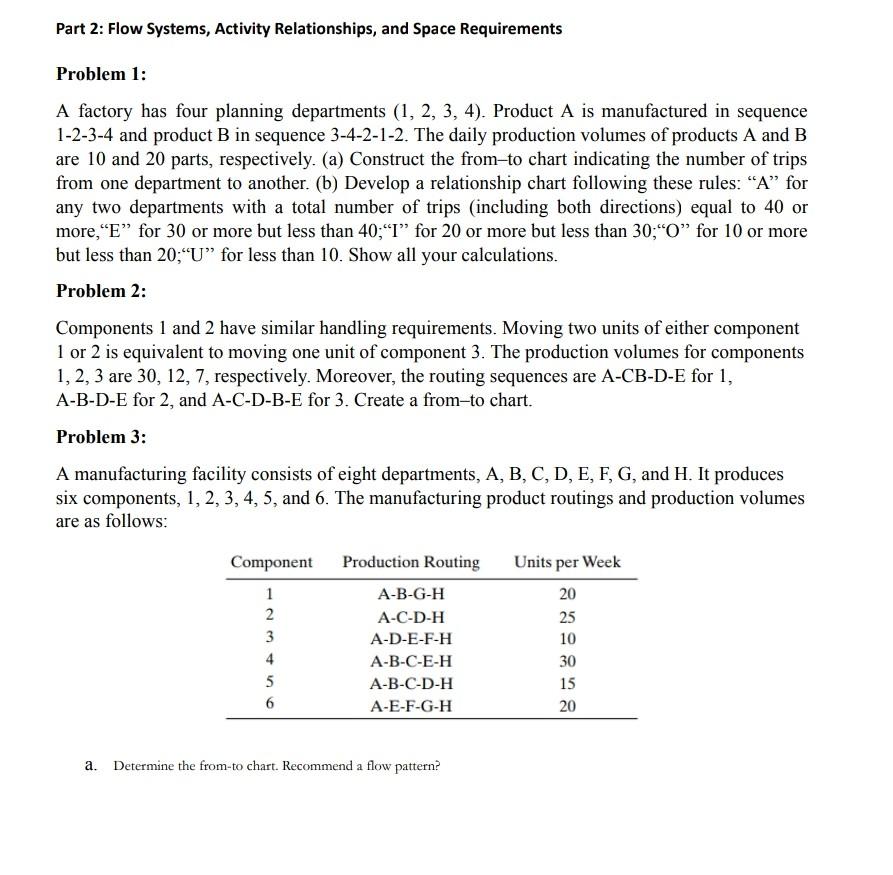

Part 2: Flow Systems, Activity Relationships, and Space Requirements Problem 1: A factory has four planning departments (1,2,3,4). Product A is manufactured in sequence 1-2-3-4 and product B in sequence 3-4-2-1-2. The daily production volumes of products A and B are 10 and 20 parts, respectively. (a) Construct the from-to chart indicating the number of trips from one department to another. (b) Develop a relationship chart following these rules: "A" for any two departments with a total number of trips (including both directions) equal to 40 or more, "E" for 30 or more but less than 40 ;"I" for 20 or more but less than 30 ;" O " for 10 or more but less than 20;; U" for less than 10 . Show all your calculations. Problem 2: Components 1 and 2 have similar handling requirements. Moving two units of either component 1 or 2 is equivalent to moving one unit of component 3 . The production volumes for components 1,2,3 are 30,12,7, respectively. Moreover, the routing sequences are A-CB-D-E for 1 , A-B-D-E for 2, and A-C-D-B-E for 3. Create a from-to chart. Problem 3: A manufacturing facility consists of eight departments, A, B, C, D, E, F, G, and H. It produces six components, 1,2,3,4,5, and 6 . The manufacturing product routings and production volumes are as follows: a. Determine the from-to chart. Recommend a flow pattern

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts