Question: PART 4 : LEAN OPERATIONS Part 4 is the continuation of Part 3 . Part 3 is mainly about how the restaurant operates given the

PART : LEAN OPERATIONS

Part is the continuation of Part Part is mainly about how the restaurant operates given

the current settings. Part goes further to identify wastes and eliminate them, which is the

notion of lean operations. To enrich your work, you would need to review and apply the

concepts of lean operations in Module and methods of process improvements in Module

In your report of this part, you need to present the following:

a Explicitly state the wastes that you see in the Uprofile in Part State if the process is

balanced or not. Briefly discuss the effects of the wastes on production, revenue, and profit.

b A brief proposal on how to eliminate the wastes that you find. Hint: labor reconfiguration

c A new Extended Table to show how your proposal in b can work. Essentially, you would do

some experiments trials and errors with the new Extended Table in Excel where:

The total number of employees stays unchanged throughout your experiment.

Assume that you already crosstrained the workers and, hence, you can easily move them

around the resources.

The number of workers at one resource can be understood as the percentages of time they

work at that resource or station for example: two workers work full time or and the third

worker spends only of hisher time at that station Thus, the number of workers can be

presented as a decimal number for example: workers

You can move the workers around the resources with increments as fine as workers.

With a new labor setup, you should achieve all utilizationPart Confused on how to calculate the new processing times to balance the IU profile. Please help

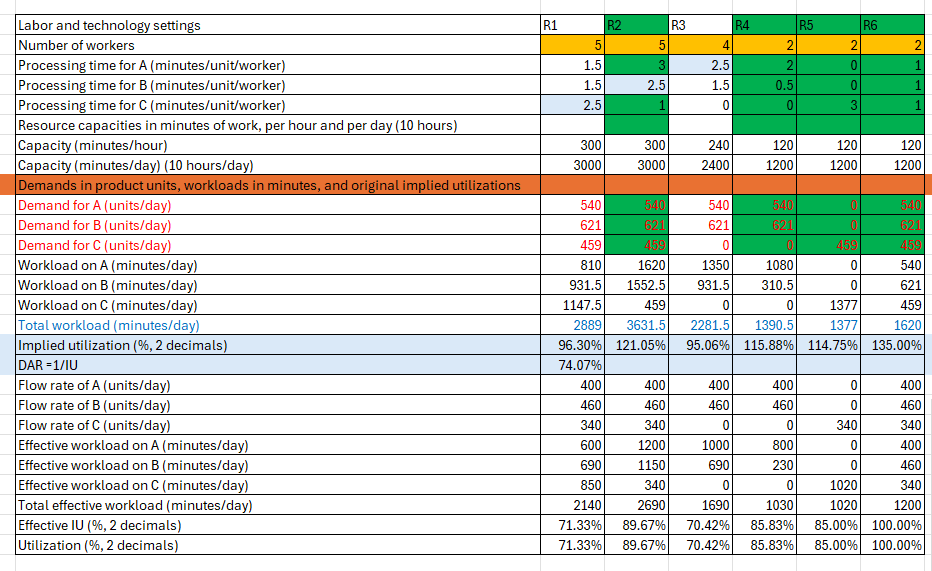

tableLabor and technology settings,RRRsqrtRbar Rbar RNumber of workers,Processing time for A minutesunitworkerProcessing time for B minutesunitworkerProcessing time for C minutesunitworkerResource capacities in minutes of work, per hour and per day hoursCapacity minuteshourCapacity minutesday hoursdayDemands in product units, workloads in minutes, and original implied utilizationsDemand for A unitsdayDemand for B unitsdayDemand for C unitsdayWorkload on A minutesdayWorkload on B minutesdayWorkload on C minutesdayTotal workload minutesdaytableImplied utilization decimalstabletableDAR IUFlow rate of A unitsdayFlow rate of B unitsdayFlow rate of C unitsdayEffective workload on A minutesdayEffective workload on B minutesdayEffective workload on C minutesdayTotal effective workload minutesdayEffective IU decimalsUtilization decimals

is the continuation of Part Part is mainly about how the restaurant operates given

the current settings. Part goes further to identify wastes and eliminate them, which is the

notion of lean operations. To enrich your work, you would need to review and apply the

concepts of lean operations in Module and methods of process improvements in Module

In your report of this part, you need to present the following:

a Explicitly state the wastes that you see in the Uprofile in Part State if the process is

balanced or not. Briefly discuss the effects of the wastes on production, revenue, and profit.

b A brief proposal on how to eliminate the wastes that you find. Hint: labor reconfiguration

c A new Extended Table to show how your proposal in b can work. Essentially, you would do

some experiments trials and errors with the new Extended Table in Excel where:

The total number of employees stays unchanged throughout your experiment.

Assume that you already crosstrained the workers and, hence, you can easily move them

around the resources.

The number of workers at one resource can be understood as the percentages of time they

work at that resource or station for example: two workers work full time or and the third

worker spends only of hisher time at that station Thus, the number of workers can be

presented as a decimal number for example: workers

You can move the workers around the resources with increments as fine as workers.

With a new labor setup, you should achieve all utilizations close to eg more than

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock