Question: Part A Teloxy Engineering has received a onetime contract to design and build 10,000 units of a new product. During the proposal process, management felt

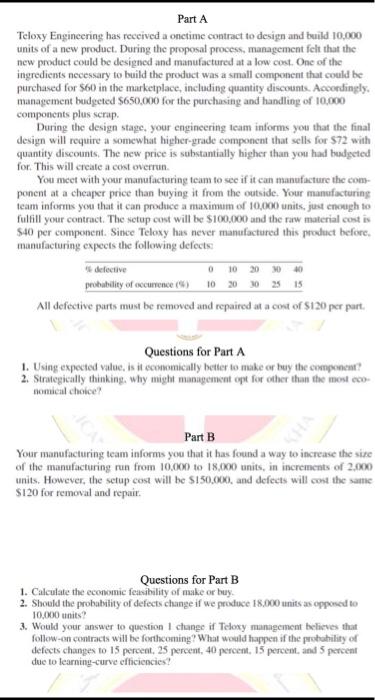

Part A Teloxy Engineering has received a onetime contract to design and build 10,000 units of a new product. During the proposal process, management felt that the new product could be designed and manufactured at a low cost. One of the ingredients necessary to build the product was a small component that could be purchased for $60) in the marketplace, including quantity discounts. Accordingly, management budgeted $650,000 for the purchasing and handling of 10,000 components plus scrap. During the design stage, your engineering team informs you that the final design will require a somewhat higher-grade component that sells for $72 with quantity discounts. The new price is substantially higher than you had budgeted for. This will create a cost overrun You meet with your manufacturing team to see if it can manufacture the com- ponent at a cheaper price than buying it from the outside. Your manufacturing team inform you that it can produce a maximum of 10,000 units, just enough to fulfill your contract. The setup cost will be $100.000 and the raw material cost is $40 per component. Since Teloxy has never manufactured this product before, manufacturing expects the following defects defective 0 10 20 30 40 probability of occurrence (8) 10 20 30 25 15 All defective parts must be removed and repaired at a cost of $120 per part Questions for Part A 1. Using expected value, is it economically better to make or buy the component? 2. Strategically thinking. Why might management opt for other than the most eco nomical choice Part B Your manufacturing team informs you that it has found a way to increase the size of the manufacturing run from 10.000 to 18.000 units, in increments of 2.000 units. However, the setup cost will be $150,000), and defects will cost the same S120 for removal and repair. Questions for Part B 1. Calculate the economic feasibility of make or buy 2. Should the probability of defects change if we produce 18.000 units as opposed to 10,000 units? 3. Would your answer to question I change if Teloxy management believes that follow-on contracts will be forthcoming? What would happen if the probability of defects changes to 15 percent, 25 percent, 40 percent, 15 percent, and 5 percent due to learning-curve efficiencies