Question: Part I: Problems #2, 3, 4, and 5 from textbook (Ch.2) Part I: Case Study in Process analysis & cont. Improvement The ACORN Corp. operates

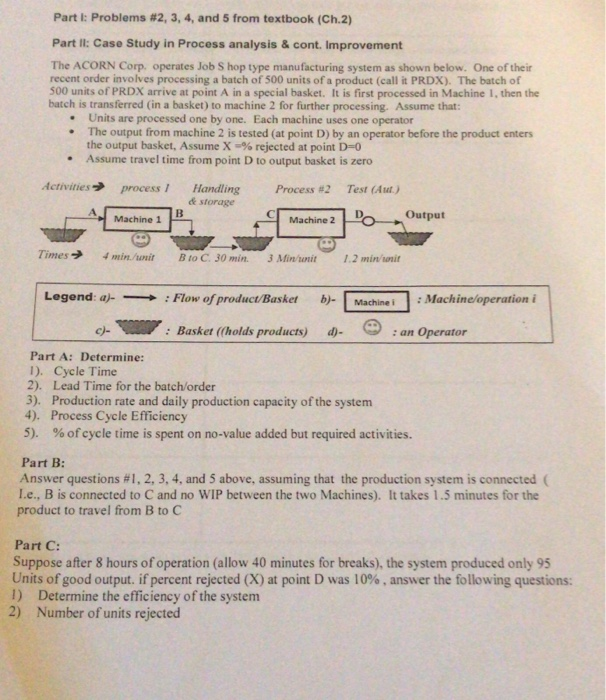

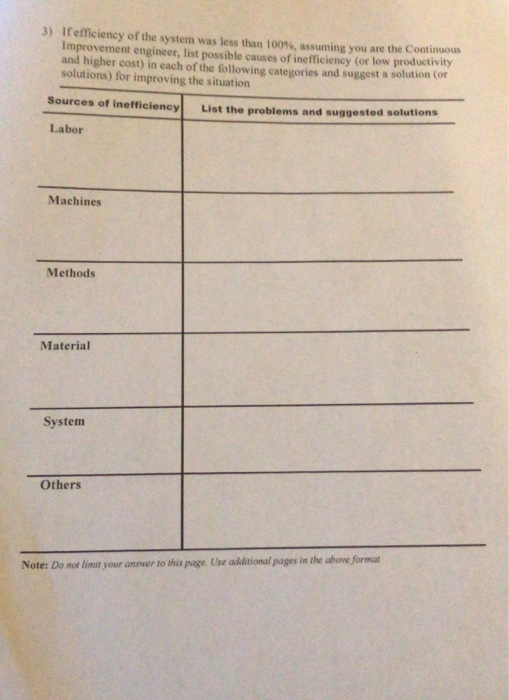

Part I: Problems #2, 3, 4, and 5 from textbook (Ch.2) Part I: Case Study in Process analysis & cont. Improvement The ACORN Corp. operates Job Shop type manufacturing system as shown below. One of their recent order involves processing a batch of 500 units of a product (call it PRDX). The batch of 500 units of PRDX arrive at point A in a special basket. It is first processed in Machine 1, then the batch is transferred (in a basket) to machine 2 for further processing. Assume that: Units are processed one by one. Each machine uses one operator The output from machine 2 is tested (at point D) by an operator before the product enters the output basket, Assume X -% rejected at point D=0 Assume travel time from point D to output basket is zero Activities process / Handling storage Process #2 Test (Aut) Do Output Machine 1 Machine 2 Times mi t B to C. 30 min. 3 Min . 2 min Legend: a)- - : Flow of product/Basket b)- Machine : Machine operation i : Basket ((holds products) d) : an Operator Part A: Determine: 1). Cycle Time 2). Lead Time for the batch/order 3). Production rate and daily production capacity of the system 4). Process Cycle Efficiency 5). % of cycle time is spent on no-value added but required activities. Part B: Answer questions #1, 2, 3, 4, and 5 above, assuming that the production system is connected I.e., B is connected to C and no WIP between the two Machines). It takes 1.5 minutes for the product to travel from B to C Part C: Suppose after 8 hours of operation (allow 40 minutes for breaks), the system produced only 95 Units of good output. if percent rejected (X) at point D was 10%, answer the following questions: 1) Determine the efficiency of the system 2) Number of units rejected 3) Ieticiency of the system was less than 100%, assuming you are the Continuous Improvement engineer, list possible causes of inefficiency (or low productivity and higher cost) in each of the following categories and suggest a solution (or solutions) for improving the situation Sources of inefficiency List the problems and suggested solutions Labor Machines Methods Material System Others Note: Do not limit your answer to this page. Use additional pages in the above format 3) Ieticiency of the system was less than 100%, assuming you are the Continuous Improvement engineer, list possible causes of inefficiency (or low productivity and higher cost) in each of the following categories and suggest a solution (or solutions) for improving the situation Sources of inefficiency List the problems and suggested solutions Labor Machines Methods Material System Others Note: Do not limit your answer to this page. Use additional pages in the above format Part I: Problems #2, 3, 4, and 5 from textbook (Ch.2) Part I: Case Study in Process analysis & cont. Improvement The ACORN Corp. operates Job Shop type manufacturing system as shown below. One of their recent order involves processing a batch of 500 units of a product (call it PRDX). The batch of 500 units of PRDX arrive at point A in a special basket. It is first processed in Machine 1, then the batch is transferred (in a basket) to machine 2 for further processing. Assume that: Units are processed one by one. Each machine uses one operator The output from machine 2 is tested (at point D) by an operator before the product enters the output basket, Assume X -% rejected at point D=0 Assume travel time from point D to output basket is zero Activities process / Handling storage Process #2 Test (Aut) Do Output Machine 1 Machine 2 Times mi t B to C. 30 min. 3 Min . 2 min Legend: a)- - : Flow of product/Basket b)- Machine : Machine operation i : Basket ((holds products) d) : an Operator Part A: Determine: 1). Cycle Time 2). Lead Time for the batch/order 3). Production rate and daily production capacity of the system 4). Process Cycle Efficiency 5). % of cycle time is spent on no-value added but required activities. Part B: Answer questions #1, 2, 3, 4, and 5 above, assuming that the production system is connected I.e., B is connected to C and no WIP between the two Machines). It takes 1.5 minutes for the product to travel from B to C Part C: Suppose after 8 hours of operation (allow 40 minutes for breaks), the system produced only 95 Units of good output. if percent rejected (X) at point D was 10%, answer the following questions: 1) Determine the efficiency of the system 2) Number of units rejected 3) Ieticiency of the system was less than 100%, assuming you are the Continuous Improvement engineer, list possible causes of inefficiency (or low productivity and higher cost) in each of the following categories and suggest a solution (or solutions) for improving the situation Sources of inefficiency List the problems and suggested solutions Labor Machines Methods Material System Others Note: Do not limit your answer to this page. Use additional pages in the above format 3) Ieticiency of the system was less than 100%, assuming you are the Continuous Improvement engineer, list possible causes of inefficiency (or low productivity and higher cost) in each of the following categories and suggest a solution (or solutions) for improving the situation Sources of inefficiency List the problems and suggested solutions Labor Machines Methods Material System Others Note: Do not limit your answer to this page. Use additional pages in the above format