Question: Performing a DRP calculation at ABC Electronics. As the distribution inventory planning manager for ABC Electronics, you have been contacted by the manufacturing plant manager

Performing a DRP calculation at ABC Electronics.

As the distribution inventory planning manager for ABC Electronics, you have been contacted by the manufacturing plant manager regarding the projected channel demand for a high-volume item stocked everywhere in the companys distribution channel, the K200-10, DVD video recorder. The manufacturing manager needs to see the projected demand for this product over the next eight weeks.

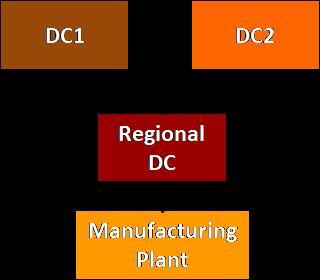

To begin the process, you have reviewed the bill of distribution kept in ABCs DRP system and have found that the distribution channel contains three echelons. You have diagramed the distribution channel and it appears as follows:

The DRP planning system also provides some critical information.

1. All of the DCs are distribution facilities only. The plant is the only facility that makes the product.

2. DCs 1 and 2 are supplied only from Regional DC.

3. The Regional DC is supplied directly from the Manufacturing Plant.

4. All of the facilities in the channel sell product to the customer, including the Manufacturing Plant.

5. Since all of the facilities are subject to independent demand, each facility has a forecast. The forecasts for DC1 and DC2 appear in the gross requirements rows on the DRP grid displayed on the next page. For Regional DC, the forecast for the eight-week planning horizon is 200 units each week. For the Manufacturing Plant, the forecast is also 200 units each week.

6. The DRP grid for the K200-10 item also shows the DRP in transit receipts that are awaiting arrival at each of the facilities.

7. Based on this information, and the planning data provided on the DRP grids displayed on the next page, calculate the projected channel demand on the Manufacturing Plant for item K200-10. Also, assist the manufacturing manager to calculate the MRP plan.

| Lead Time/weeks | 1 | DISTRIBUTION CENTER 1 | |||||||

| Order Quantity/min | 200 | ||||||||

| On Hand Inventory/units | 50 | WEEKLY PERIODS | |||||||

| PRODUCT - K200-10 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Gross Requirements | 250 | 250 | 300 | 300 | 350 | 350 | 375 | 375 | |

| DRP In Transit Receipts | 300 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Projected Available Balance | |||||||||

| Net Requirements | |||||||||

| DRP Planned Order Receipt | |||||||||

| DRP Planned Order Release | |||||||||

| Lead Time/weeks | 1 | DISTRIBUTION CENTER 2 | |||||||

| Order Quantity/min | 100 | ||||||||

| On Hand Inventory/units | 50 | WEEKLY PERIODS | |||||||

| PRODUCT - K200-10 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Gross Requirements | 175 | 175 | 200 | 200 | 200 | 225 | 225 | 250 | |

| DRP In Transit Receipts | 175 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Projected Available Balance | |||||||||

| Net Requirements | |||||||||

| DRP Planned Order Receipt | |||||||||

| DRP Planned Order Release | |||||||||

| Lead Time/weeks | 1 | REGIONAL DISTRIBUTION CENTER | |||||||

| Order Quantity/min | 525 | ||||||||

| Forecast/weekly | 200 | ||||||||

| On Hand Inventory/units | 100 | WEEKLY PERIODS | |||||||

| PRODUCT - K200-10 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Gross Requirements | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| DRP In Transit Receipts | 525 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Projected Available Balance | |||||||||

| Net Requirements | |||||||||

| DRP Planned Order Receipt | |||||||||

| DRP Planned Order Release | |||||||||

| Lead Time/weeks | 2 | MANUFACTURING PLANT | |||||||

| Order Quantity | 1,000 | ||||||||

| Forecast/weekly | 200 | ||||||||

| On Hand Inventory/units | 700 | WEEKLY PERIODS | |||||||

| PRODUCT - K200-10 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Gross Requirements | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| MRP Scheduled Receipts | 1000 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Projected Available Balance | |||||||||

| Net Requirements | |||||||||

| MRP Planned Order Receipt | |||||||||

| MRP Planned Order Release |

Regional DC Manuifactituring: Plant

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts