Question: PLEASE ANSWER 1-7 WILL RATE 1 THROUGH 7 EVERY QUESTION THANK YOU Brandons Boards makes reasonably high-end skateboards which sell for $ 5 00 each.

PLEASE ANSWER 1-7 WILL RATE

1 THROUGH 7 EVERY QUESTION THANK YOU

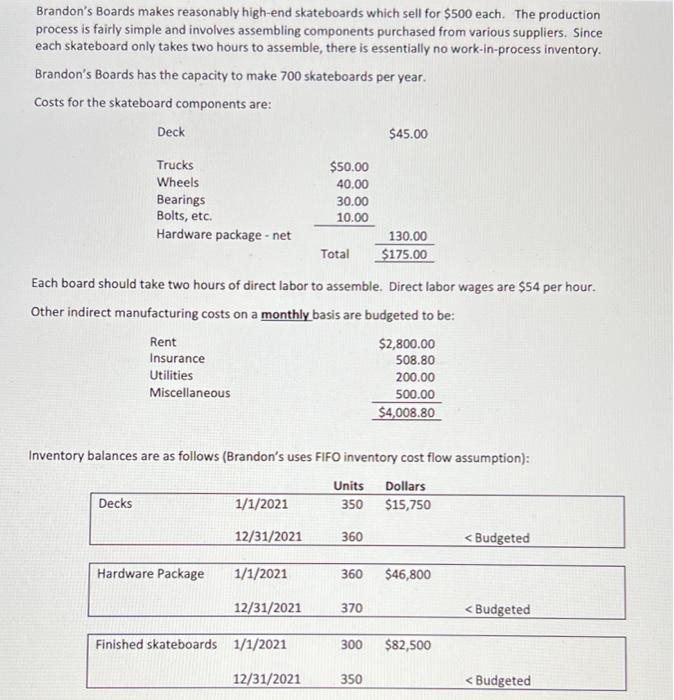

Brandons Boards makes reasonably high-end skateboards which sell for $500 each. The production process is fairly simple and involves assembling components purchased from various suppliers. Since each skateboard only takes two hoursto assemble, there is essentially no work-in-process inventory.

Brandons Boards has the capacity to make 700 skateboards per year.

Costs for the skateboard components are:

| Deck |

| $45.00 |

|

|

|

|

|

|

| Trucks | $50.00 |

|

|

| Wheels | 40.00 |

|

|

| Bearings | 30.00 |

|

|

| Bolts, etc. | 10.00 |

|

|

| Hardware package - net |

| 130.00 |

|

|

| Total | $175.00 |

|

|

|

|

|

|

Each board should take two hours of direct labor to assemble. Direct labor wages are $54 per hour.

Other indirect manufacturing costs on a monthly basis arebudgeted to be:

| Rent | $2,800.00 |

|

| Insurance | 508.80 |

|

| Utilities | 200.00 |

|

| Miscellaneous | 500.00 |

|

|

| $4,008.80 |

|

Inventory balances are as follows (Brandons uses FIFO inventory cost flow assumption):

|

|

| Units | Dollars |

|

| Decks | 1/1/2021 | 350 | $15,750 |

|

|

|

|

|

|

|

|

| 12/31/2021 | 360 |

| |

|

|

|

|

|

|

| Hardware Package | 1/1/2021 | 360 | $46,800 |

|

|

|

|

|

|

|

|

| 12/31/2021 | 370 |

| |

|

|

|

|

|

|

| Finished skateboards | 1/1/2021 | 300 | $82,500 |

|

|

|

|

|

|

|

|

| 12/31/2021 | 350 |

| |

|

|

|

|

|

|

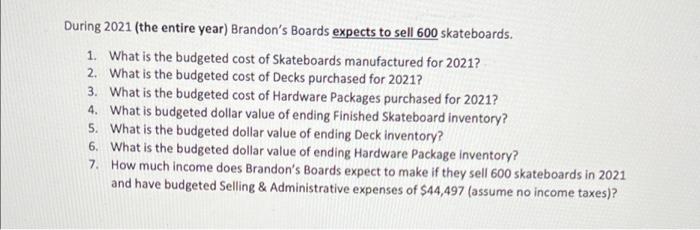

During 2021 (the entire year) Brandons Boards expects to sell 600 skateboards.

Brandon's Boards makes reasonably high-end skateboards which sell for $500 each. The production process is fairly simple and involves assembling components purchased from various suppliers. Since each skateboard only takes two hours to assemble, there is essentially no work-in-process inventory. Brandon's Boards has the capacity to make 700 skateboards per year. Costs for the skateboard components are: Deck $45.00 Trucks Wheels Bearings Bolts, etc. Hardware package - net $50.00 40,00 30.00 10.00 130.00 Total $175.00 Each board should take two hours of direct labor to assemble. Direct labor wages are $54 per hour. Other indirect manufacturing costs on a monthly basis are budgeted to be: Rent $2,800.00 Insurance 508.80 Utilities 200.00 Miscellaneous 500.00 $4,008.80 Inventory balances are as follows (Brandon's uses FIFO inventory cost flow assumption): Decks 1/1/2021 Units Dollars 350 $15,750 12/31/2021 360

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts