Question: The questions under the case study below which i need to be answered based on this study with reference to the case study: Which can

The questions under the case study below which i need to be answered based on this study

with reference to the case study:

with reference to the case study:

Which can be found in the Total Quality Management and Operational Excellence book

TQM objectives management process in Nissan

please answer the following questions:

1. Evaluate the Hoshin Kanri based approach of objectives management adopted by Nissan, in relation to the nature of their business in the automotive sector; could this type of approach be adapted for an organization operating in the health or education sector?

2. Discuss the leadership, commitment and strategic requirements of the type of approach used in Nissan.

3. What role could benchmarking play in the development of the OMP methods used?

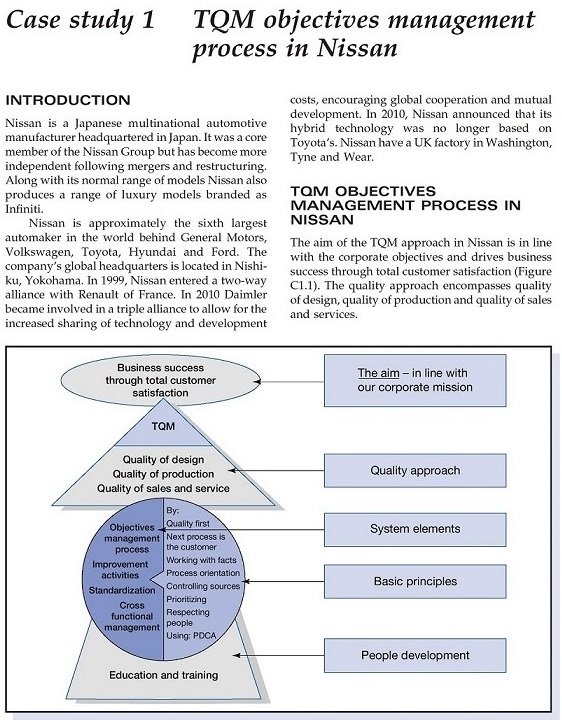

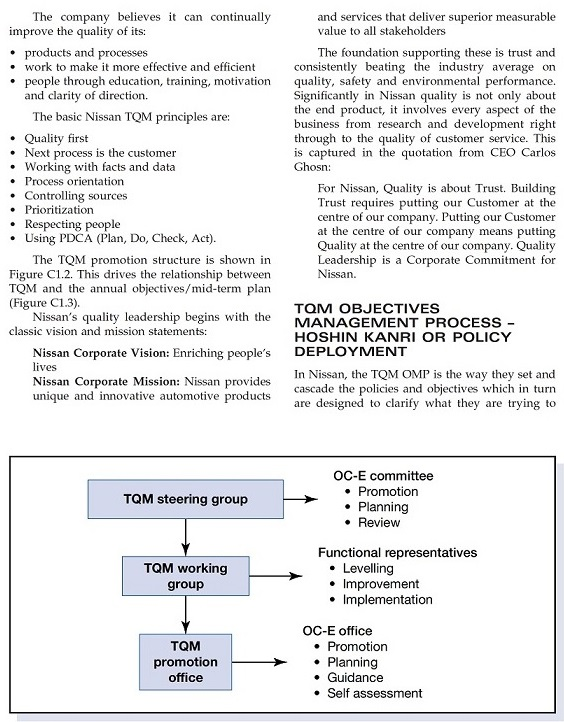

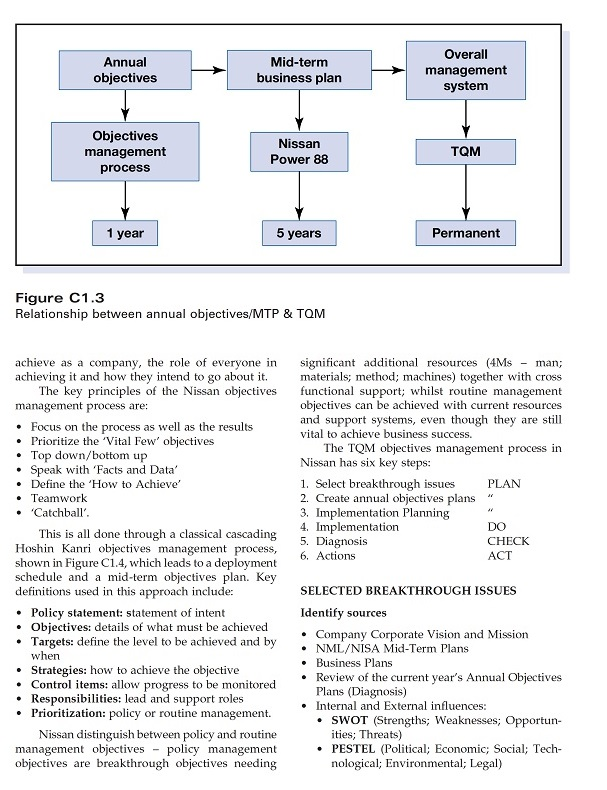

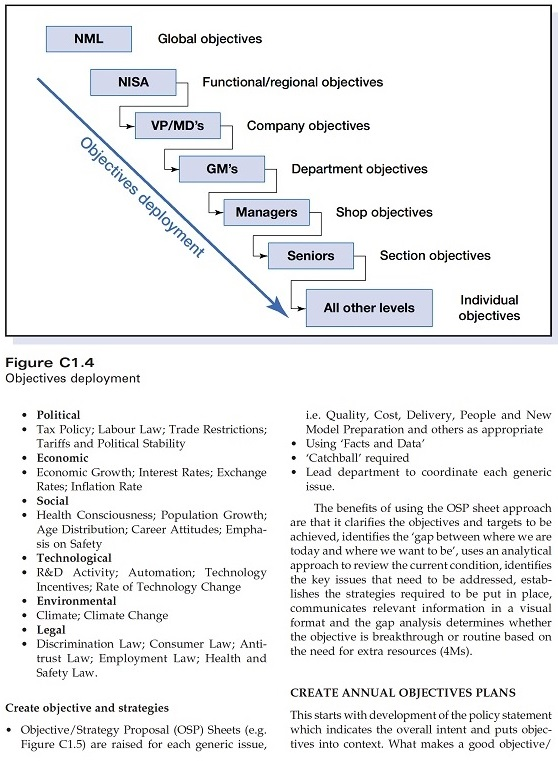

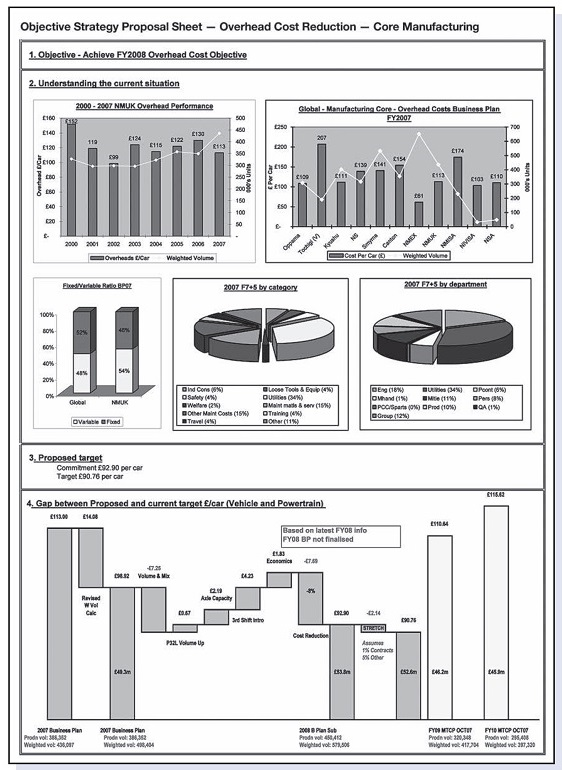

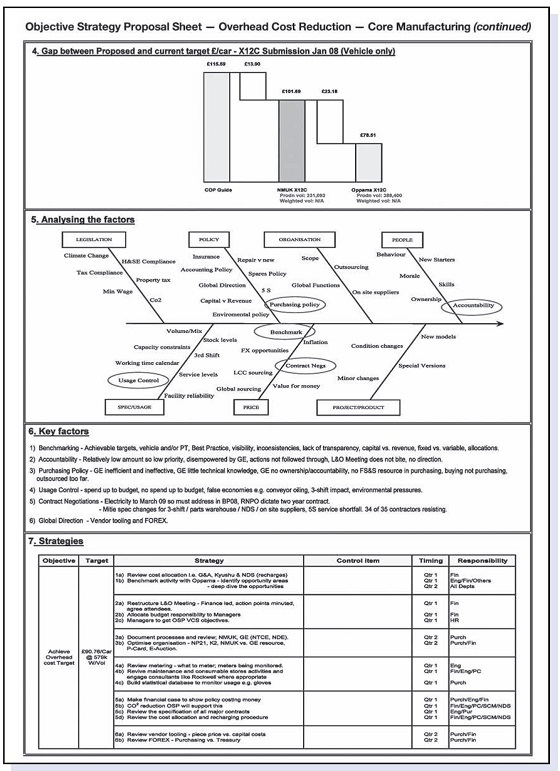

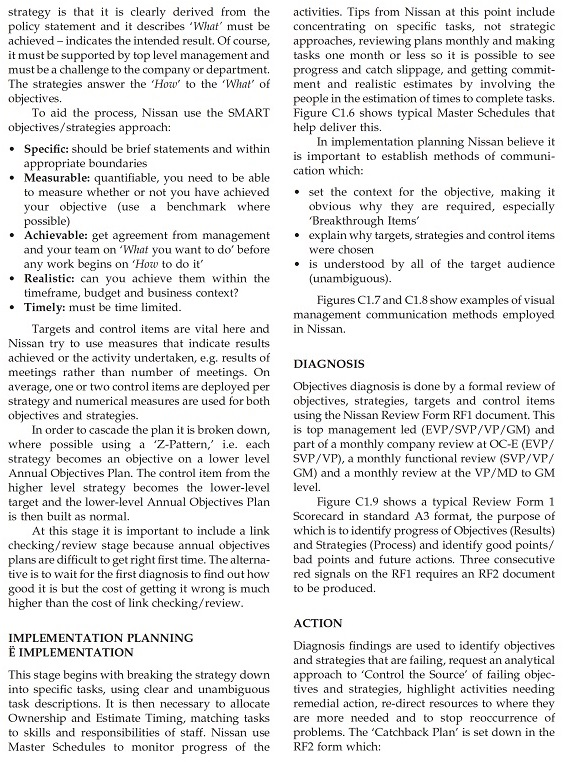

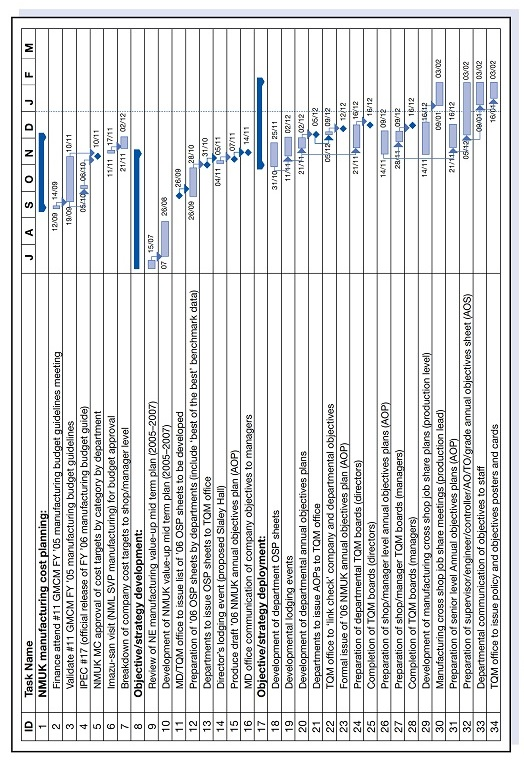

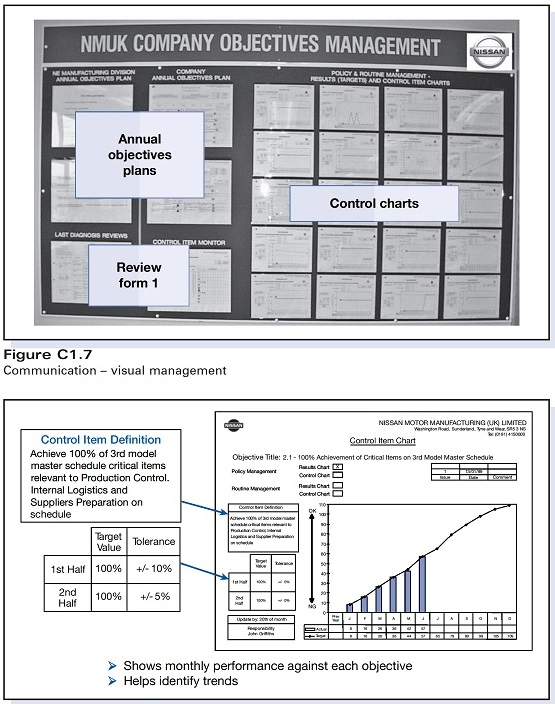

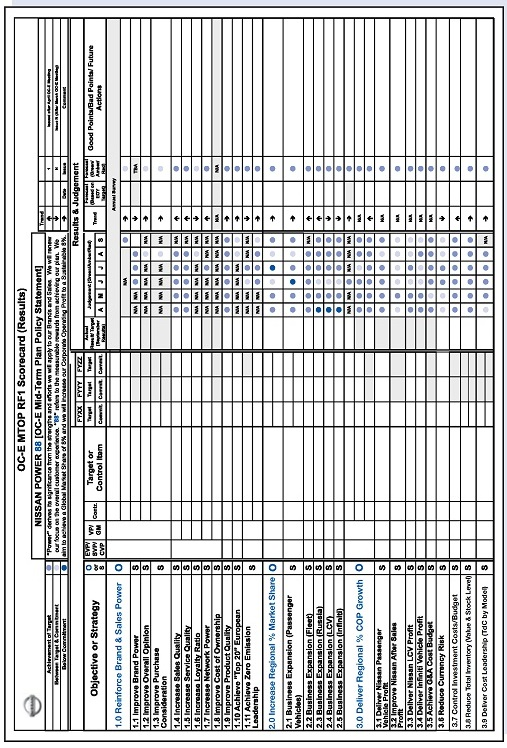

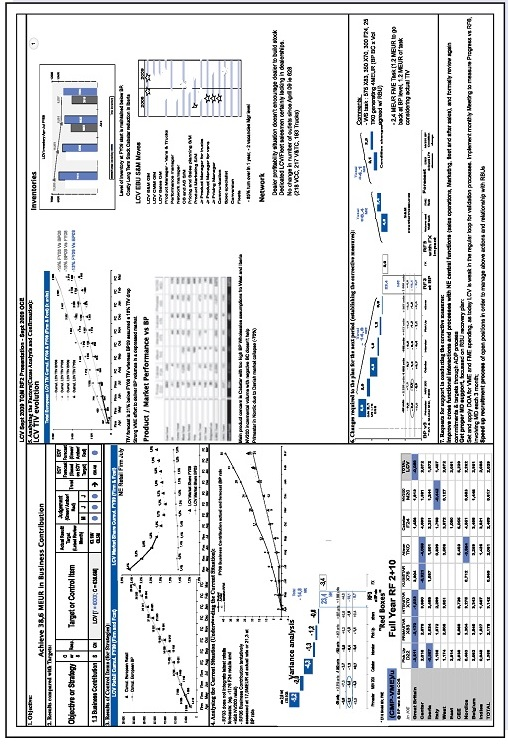

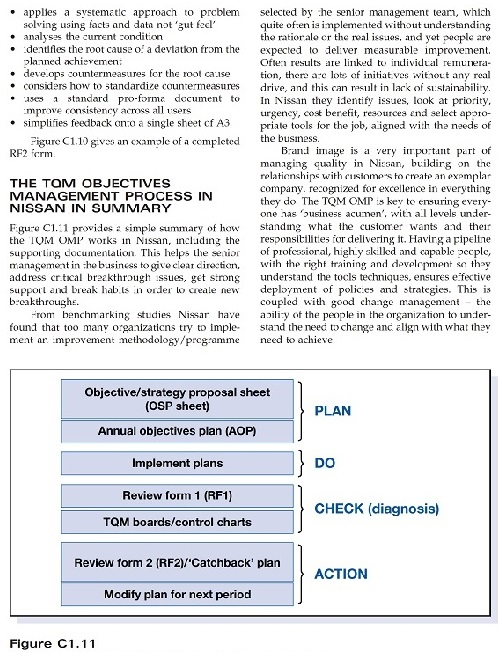

Case study 1 TQM objectives management process in Nissan costs, encouraging global cooperation and mutual development. In 2010, Nissan announced that its hybrid technology was no longer based on Toyota's. Nissan have a UK factory in Washington, Tyne and Wear. INTRODUCTION Nissan is a Japanese multinational automotive manufacturer headquartered in Japan. It was a core member of the Nissan Group but has become more independent following mergers and restructuring. Along with its normal range of models Nissan also produces a range of luxury models branded as Infiniti. Nissan is approximately the sixth largest automaker in the world behind General Motors, Volkswagen, Toyota, Hyundai and Ford. The company's global headquarters is located in Nishi- ku, Yokohama. In 1999, Nissan entered a two-way alliance with Renault of France. In 2010 Daimler became involved in a triple alliance to allow for the increased sharing of technology and development TOM OBJECTIVES MANAGEMENT PROCESS IN NISSAN The aim of the TQM approach in Nissan is in line with the corporate objectives and drives business success through total customer satisfaction (Figure C1.1). The quality approach encompasses quality of design, quality of production and quality of sales and services. Business success through total customer satisfaction The aim - in line with our corporate mission TQM Quality of design Quality of production Quality of sales and service Quality approach System elements . Objectives Quality firs management Next process is process the customer Working with facts Improvement activities Process orientation Standardization Controlling sources Prioritizing Cross functional Respecting management people Using: PDCA Basic principles People development Education and training and services that deliver superior measurable value to all stakeholders The company believes it can continually improve the quality of its: products and processes work to make it more effective and efficient people through education, training, motivation and clarity of direction. The basic Nissan TQM principles are: Quality first Next process is the customer Working with facts and data Process orientation Controlling sources Prioritization Respecting people Using PDCA (Plan, Do, Check, Act). The TQM promotion structure is shown in Figure C1.2. This drives the relationship between TQM and the annual objectives/mid-term plan (Figure C1.3). Nissan's quality leadership begins with the classic vision and mission statements: Nissan Corporate Vision: Enriching people's lives Nissan Corporate Mission: Nissan provides unique and innovative automotive products The foundation supporting these is trust and consistently beating the industry average on quality, safety and environmental performance. Significantly in Nissan quality is not only about the end product, it involves every aspect of the business from research and development right through to the quality of customer service. This is captured in the quotation from CEO Carlos Ghosn: For Nissan, Quality is about Trust. Building Trust requires putting our Customer at the centre of our company. Putting our Customer at the centre of our company means putting Quality at the centre of our company. Quality Leadership is a Corporate Commitment for Nissan. TQM OBJECTIVES MANAGEMENT PROCESS - HOSHIN KANRI OR POLICY DEPLOYMENT In Nissan, the TOM OMP is the way they set and cascade the policies and objectives which in turn are designed to clarify what they are trying to TQM steering group OC-E committee Promotion Planning Review TQM working group Functional representatives Levelling Improvement Implementation TQM promotion office OC-E office Promotion Planning Guidance Self assessment Annual objectives Mid-term business plan Overall management system Objectives management process Nissan Power 88 TQM 1 year 5 years Permanent Figure C1.3 Relationship between annual objectives/MTP & TQM significant additional resources (4Ms - man; materials; method; machines) together with cross functional support; whilst routine management objectives can be achieved with current resources and support systems, even though they are still vital to achieve business success. The TQM objectives management process in Nissan has six key steps: 1. Select breakthrough issues PLAN 2. Create annual objectives plans" 3. Implementation Planning 4. Implementation DO 5. Diagnosis CHECK 6. Actions ACT achieve as a company, the role of everyone in achieving it and how they intend to go about it. The key principles of the Nissan objectives management process are: Focus on the process as well as the results Prioritize the 'Vital Few' objectives Top down/bottom up Speak with 'Facts and Data' Define the 'How to Achieve' Teamwork . 'Catchball'. This is all done through a classical cascading Hoshin Kanri objectives management process, shown in Figure C1.4, which leads to a deployment schedule and a mid-term objectives plan. Key definitions used in this approach include: Policy statement: statement of intent Objectives: details of what must be achieved Targets: define the level to be achieved and by when Strategies: how to achieve the objective Control items: allow progress to be monitored Responsibilities: lead and support roles Prioritization: policy or routine management. Nissan distinguish between policy and routine management objectives - policy management objectives are breakthrough objectives needing SELECTED BREAKTHROUGH ISSUES Identify sources Company Corporate Vision and Mission NML/NISA Mid-Term Plans Business Plans Review of the current year's Annual Objectives Plans (Diagnosis) Internal and external influences: SWOT (Strengths; Weaknesses; Opportun- ities; Threats) PESTEL (Political; Economic; Social; Tech- nological; Environmental; Legal) NML Global objectives NISA Functional/regional objectives VP/MD's Company objectives Objectives deployment GM's Department objectives Managers Shop objectives Seniors Section objectives All other levels Individual objectives Figure C1.4 Objectives deployment Political Tax Policy; Labour Law; Trade Restrictions; Tariffs and Political Stability Economic Economic Growth; Interest Rates; Exchange Rates; Inflation Rate Social Health Consciousness; Population Growth; Age Distribution; Career Attitudes; Empha- sis on Safety Technological R&D Activity; Automation; Technology Incentives; Rate of Technology Change Environmental Climate; Climate Change Legal Discrimination Law; Consumer Law; Anti- trust Law; Employment Law; Health and Safety Law. i.e. Quality, Cost, Delivery, People and New Model Preparation and others as appropriate Using 'Facts and Data' 'Catchball' required Lead department to coordinate each generic issue. The benefits of using the OSP sheet approach are that it clarifies the objectives and targets to be achieved, identifies the gap between where we are today and where we want to be', uses an analytical approach to review the current condition, identifies the key issues that need to be addressed, estab- lishes the strategies required to be put in place, communicates relevant information in a visual format and the gap analysis determines whether the objective is breakthrough or routine based on the need for extra resources (4M). Create objective and strategies Objective/Strategy Proposal (OSP) Sheets (eg. Figure C1.5) are raised for each generic issue, CREATE ANNUAL OBJECTIVES PLANS This starts with development of the policy statement which indicates the overall intent and puts objec- tives into context. What makes a good objective/ Objective Strategy Proposal Sheet - Overhead Cost Reduction - Core Manufacturing 1. Objective - Achieve FY2008 Overhead Cost Obloctive 2. Understanding the current situation 2000 - 2007 NMUK Overhead Performance Global - Manufacturing Core - Overhead Coats Business Plan 8 8 CH 8 1306141 Overcar 150 Units 8 Ha 8 s 8 50+ 8 2000 2001 2002 2003 2004 Overhede CCP 2005 2006 2007 Waighted Volume D Cost Per Car Weld Volume Flertaletto B.222 2007 F745. by category 2007 745 by department Safety (4%) BLose Tools & Equip Ds) Monts er (15%) NUK Deng (18) BU () owhand ( 1 M (11%) PO/Sparta (0) Prod (10%) Grop (29 Pont (0%) Pers ) BOA (1%) Other Maint Costs (15%) Vatable around 3. Proposed target Commitment 92.90 per car Target 90.78 per car 4. Gap between Proposed and current target /car Vehicle and Powertrain) 193.00 Based on latest F YOB into FYON BP not finalised 12 Volume 433 29 Aude Capacity DOT 02. 0 2 .14 3rd s C adu Pa Volume Up me Business Plan 2007 Bus Plan Prode Weigd vol 8,404 Weld vol 490,00 Proto 442 Weighted vol. 52,305 Prorok 2 3 Pinyol: 215. godt 412.704 Wegd vot 27,330 Objective Strategy Proposal Sheet - Overhead Cost Reduction - Core Manufacturing (continued) 4. Gap between Proposed and current target Elcar - X12C Submission Jan 08 (Vehicle only) 5. Analysing the factors LEELATION PEOPLE Ce change New Starters Tax Compliance Property tax the coge Accounting Polly Spare Polly Global Direction Global Punctions Capital Revene rastin e Ossipples Blanchmark New models Inflation Vetuma Mix Capely costs Ind St Working time calendar Comic changes opper OC Center Service levels Lage Value for money in the rely o l baltore 6. Key factors 1) Benchmarking - Achievable targets vehicle ander PT. Best Practice, vistyinconsistenci lack of transparency, cap a venue food v vabe, allons 2) Accountability. Relatively low amount so low priority, disempowered by GE, actions not followed through, Lao Mosting does not be, no direction 3) Purchasing Policy GE inefficient and ineffective, Ele technical knowledge, GE no ownership accountability, no F848 resource in purchasing, buying not purchasing. Outsourced too far 4) Usage Control - spend up to budget to spend up to budget, ale economic conveyor oling. 3-shift impact environmental pressures 5) Contract Negotiations - Electricity to March 0 som address in PORNPO dictatoto wear contract - M ospec changes for 3-shit/parts warehouse/ NOS/onsite suppliers, 5$ service shortfall 34 of 35 contractors resisting 6) Global Direction. Vendor tooling and FOREX 7. Strategies Objective Target Strategy Control item T iming Responsibility co n ta OSA. Kush &NDS recharges Benchmarkity winema Nervitooruniter Restructure LAO Meeting Finance led action point mind and review NWUK, GENTCE, NDE) 3 or PC FEOPO/SCMNDS FIVE OPCOMINDS strategy is that it is clearly derived from the policy statement and it describes 'What' must be achieved - indicates the intended result. Of course, it must be supported by top level management and must be a challenge to the company or department. The strategies answer the 'How to the 'What' of objectives. To aid the process, Nissan use the SMART objectives/strategies approach: Specific: should be brief statements and within appropriate boundaries Measurable: quantifiable, you need to be able to measure whether or not you have achieved your objective (use a benchmark where possible) Achievable: get agreement from management and your team on 'What you want to do before any work begins on 'How to do it' Realistic: can you achieve them within the timeframe, budget and business context? Timely: must be time limited. Targets and control items are vital here and Nissan try to use measures that indicate results achieved or the activity undertaken, e.g. results of meetings rather than number of meetings. On average, one or two control items are deployed per strategy and numerical measures are used for both objectives and strategies. In order to cascade the plan it is broken down, where possible using a 'Z-Pattern,' i.e. each strategy becomes an objective on a lower level Annual Objectives Plan. The control item from the higher level strategy becomes the lower-level target and the lower-level Annual Objectives Plan is then built as normal. At this stage it is important to include a link checking/review stage because annual objectives plans are difficult to get right first time. The alterna- tive is to wait for the first diagnosis to find out how good it is but the cost of getting it wrong is much higher than the cost of link checking/review. activities. Tips from Nissan at this point include concentrating on specific tasks, not strategic approaches, reviewing plans monthly and making tasks one month or less so it is possible to see progress and catch slippage, and getting commit- ment and realistic estimates by involving the people in the estimation of times to complete tasks. Figure C1.6 shows typical Master Schedules that help deliver this. In implementation planning Nissan believe it is important to establish methods of communi- cation which: set the context for the objective, making it obvious why they are required, especially Breakthrough Items' explain why targets, strategies and control items were chosen is understood by all of the target audience (unambiguous). Figures C1.7 and C1.8 show examples of visual management communication methods employed in Nissan DIAGNOSIS Objectives diagnosis is done by a formal review of objectives, strategies, targets and control items using the Nissan Review Form RF1 document. This is top management led (EVP/SVP/VP/GM) and nthly company review at OC-E (EVP/ SVP/VP), a monthly functional review (SVP/VP/ GM) and a monthly review at the VP/MD to GM level. Figure C1.9 shows a typical Review Form 1 Scorecard in standard A3 format, the purpose of which is to identify progress of Objectives (Results) and Strategies (Process) and identify good points/ bad points and future actions. Three consecutive red signals on the RF1 requires an RF2 document to be produced. IMPLEMENTATION PLANNING IMPLEMENTATION This stage begins with breaking the strategy down into specific tasks, using clear and unambiguous task descriptions. It is then necessary to allocate Ownership and Estimate Timing, matching tasks to skills and responsibilities of staff. Nissan use Master Schedules to monitor progress of the ACTION Diagnosis findings are used to identify objectives and strategies that are failing, request an analytical approach to 'Control the Source' of failing objec- tives and strategies, highlight activities needing remedial action, re-direct resources to where they are more needed and to stop reoccurrence of problems. The 'Catchback Plan' is set down in the RF2 form which: JASON DJ 12/09 14/09 19/09 0510 06.10. 10/11 a. No 11711 21/11 10/11 17/11 02/12 h 15/07 07 2 6/08 20/ 00 26/09 2 8/10 31/10 04/11 - 0611 07/11 14/11 Task Name NMUK manufacturing cost planning: Finance attend #11 GMCM FY '05 manufacturing budget guidelines meeting Validate #11 GMCM FY '05 manufacturing budget guidelines IPEC #17 (official release of FY '06 manufacturing budget guide) NMUK MC approval of cost targets by category by department Imazu-san visit (NML SVP manufacturing) for budget approval Breakdown of company cost targets to shop/manager level Objective/strategy development: Review of NE manufacturing value-up mid term plan (2005-2007) Development of NMUK value-up midterm plan (2005-2007) MD/TOM office to issue list of '06 OSP sheets to be developed Preparation of '06 OSP sheets by departments (include 'best of the best benchmark data) Departments to issue OSP sheets to TQM office Director's lodging event (proposed Slaley Hall) Produce draft OG NMUK annual objectives plan (AOP) MD office communication of company objectives to managers Objective/strategy deployment: Development of department OSP sheets Developmental lodging events Development of departmental annual objectives plans Departments to issue AOPs to TOM office TOM office to link check' company and departmental objectives Formal issue of '06 NMUK annual objectives plan (AOP) Preparation of departmental TOM boards (directors) Completion of TOM boards (directors) Preparation of shop/manager level annual objectives plans (AOP) Preparation of shop/manager TOM boards (managers) Completion of TOM boards (managers) Development of manufacturing cross shop lob share plans (production level) Manufacturing cross shop job share meetings (production lead) Preparation of senior level Annual objectives plans (AOP) Preparation of supervisor/engineer/controller/AO/TO/grade annual objectives sheet (AOS) Departmental communication of objectives to staff TOM office to issue policy and objectives posters and cards 31/19 2011 | 20 21/11 02/12 21/11 12/12 /12 1612 09/12 09/12 16/12 1 012 090 18/12 1011 21/ 1 31 32 05/12 34 NMUK COMPANY OBJECTIVES MANAGEMENT NEMANGGISHLAN ANNUAL RECTIVES PLAN POLICY A ROUTINE MANAGEMENT ESTS TARGET AND CONTROL TEM CURTS Annual objectives plans Control charts Review form 1 Figure C1.7 Communication - visual management NISSAN MOTOR MANUFACTURING (UK LIMITED Control Item Chart Objective Title: 2.1 - 100% Achievement of Ortical Items on 3rd Model Master Schedule Pusat Pole Morgan Control Item Definition Achieve 100% of 3rd model master schedule critical items relevant to Production Control. Internal Logistics and Suppliers Preparation on schedule C her Target Value Tolerance 1st Half 100% +/- 10% 100% +/-5% Half - PU DUOTI > Shows monthly performance against each objective > Helps identify trends OC-E MTOP RF1 Scorecard (Results) NISSAN POWER 88 [OC-E Mid-Term Plan Policy Statement P e ntrum voor onder Women wur focus on the w all customer serience to the r ewards from achieving our per we tomto Glob al Servis and we were w powie Opere Preft to see Results & Judgement l e ver Objective or Strategy con control tam Good Pointa/Bad Pointed Future Actions CO 80 1.0 Reinforce Brand & Sales Power 1.1 Improve Brand Power 1.2 Improve Overall Opinion 1.3 Improve Purchase Consideration 1A Increase Saten Quality 1.5 Increase Service Quality 1.6 Increase Loyalty Ratio 1.7 Increase Network Power 1.8 Improve Cost of Ownership 1. Improve Product Quality 1.10 Achieve Top 20 European 1.11 Achieve Zero Emission Leadership CO CO CO CO CO CO 20 ODIO. COCO000000OO lllllllllllll 2.0 Increase Regional % Market Share O 2.1 Business Expansion (Passenger Vehicles) 2.2 Business Expansion Fleet) 2.3 Business Expansion Russia) 2.4 Business Expansion LCV 2.5 Business Expansion Infinit GOG 3.0 Deliver Regional % COP Growth D an Passenger 32 Improve Nissan Alter Sales 3.3 Dellver Nissan LCV Profit 3.4 Deliver Infiniti Vehicle Profit 3.5 ACHOTOGLIA cost Budget 3.6 Reduce Currency Risk 3.7 Control Investment Cost Budget 3.8 Reduce Total Inventory (Make a Stock Levels 3.9 Delver Cost Leadership (TC by Moden S LOV TV Svor Achieve 35 MEUR In Business Contribution Target or Controllam U B erola ATC -CALON NEW F ly IVYO TV MTV Product Market Performance vs SP 2 RE WARRA Network Durat Herren Beryloo wewno le Yalance analysis No change in unter den he 218 VCC, 217 VSTG 100 TWIN 18 VCC 217 244 Change rate the pleee the re lig i e Weiss X3, 360 XI, 2007, 21 - megewing ANEURIP BV w "Red Bones Full Year RF 2-10 .24 MEURIMET 2 MEUR Deck PvMUR ng sul TV iiiiiiiii pe crowd functional intercom and protected functions at there were no w iiiiiiiii at andy Or Wand Edelse opforvaltningen menyeram in Vachment pedig rent whenengo applies a systematic approach to problem solving using lacts and data not'zut fed' analyses the current condition denufles the root cause o' a deviation from the planned achievemen: deve.ops countermeasures for the root cause considers how to standardize countermeasures ases 1 standard pro-forma document to improve consistency across all users simplifies feedback on a single sheet cf A3 Figure C11 gvas an camole of a completed RF2 crm THE TOM OBJECTIVES MANAGEMENT PROCESS IN NISSAN IN SUMMARY Fgure C1.11 provides a simple summary of how the TOM OMP works in Nissan, including the supporting documentation This helps the senior management in the business to give clear direction, address critical breakthrough issues, get strong support and break hab is n order to creale new breakthroughs. From benchmarking studies Nissar have found that too many organizations try to imple meat or improvement methodology/programme selected by he senior management tean, which quite of en is implemented without understanding the ratioralo cr the real issues, and yot people are expected to deliver measurable improvement Often results are linked to individual r tion, there are lots of initiat ves without any real drive, and this can result in lack of sustainability. In Nissan they identify issues, look at priority. urgency, cost berefit, resources end select aporo- priate tools for the job, a igned with the needs of the business Bran: image is a very important part of managing quality in Nissan, buildirg on the relationships with customers to create an examplar company recognized for excellence in everything they do The TOM OMP is key te ensuring every- one has 'usiness acumen'. with all levels under- standing what the customer wants and their responsitilities for delivering it. Having a pipeline of professioral, high y skilled and capable pecple, with the right training and development so they understand the tocis techniques, ensures efective deployment of polices and strategies. This is coupled with good change management - the ability of the people in the organization to under- stand the need to change and align with what they need to achieve Objective/strategy proposal sheet (OSP sheet) PLAN Annual objectives plan (AOP) Implement plans DO Review form 1 (F1) CHECK (diagnosis) TQM boards/control charts Review form 2 (RF2)"Catchback plan ACTION Modify plan for next period Figure C1.11Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts