Question: Please answer #4 and #5 in excel format with the formulas showing. Screenshots work perfectly! 9:48 Cancel Text - operati...nd-edition.pdf ... requirements I were is

Please answer #4 and #5 in excel format with the formulas showing. Screenshots work perfectly!

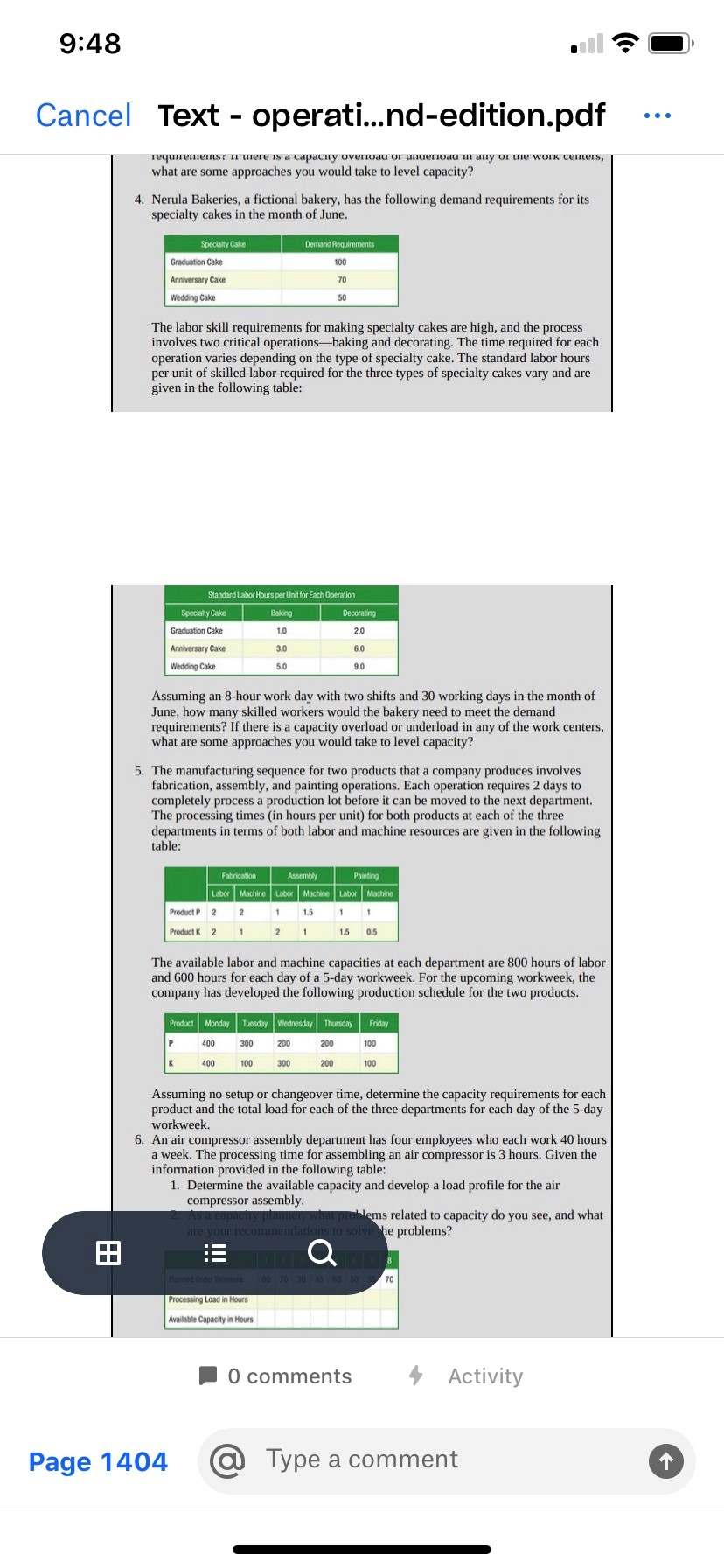

9:48 Cancel Text - operati...nd-edition.pdf ... requirements I were is a capacity uveriodu or under III duy ui ue work centers, what are some approaches you would take to level capacity? 4. Nerula Bakeries, a fictional bakery, has the following demand requirements for its specialty cakes in the month of June. Demand Requirements 100 Specialty Cake Graduation Cake Anniversary Cake Wedding Cake 70 50 The labor skill requirements for making specialty cakes are high, and the process involves two critical operationsbaking and decorating. The time required for each operation varies depending on the type of specialty cake. The standard labor hours per unit of skilled labor required for the three types of specialty cakes vary and are given in the following table: Standard Labor Hours per Unit for Each Operation Specialty Cake Baking Decorating Graduation Cake 1.0 2.0 3.0 Anniversary Cake Wedding Cake 6.0 9.0 5.0 Assuming an 8-hour work day with two shifts and 30 working days in the month of June, how many skilled workers would the bakery need to meet the demand requirements? If there is a capacity overload or underload in any of the work centers, what are some approaches you would take to level capacity? 5. The manufacturing sequence for two products that a company produces involves fabrication, assembly, and painting operations. Each operation requires 2 days to completely process a production lot before it can be moved to the next department. The processing times in hours per unit) for both products at each of the three departments in terms of both labor and machine resources are given in the following table: Painting Fabrication Assembly Labor Machine Labor Machine Labor Machine Product P2 2 1 1.5 Product K 2 1 2 1 1.5 0.5 The available labor and machine capacities at each department are 800 hours of labor and 600 hours for each day of a 5-day workweek. For the upcoming workweek, the company has developed the following production schedule for the two products. Friday Product Monday Tuesday Wednesday Thursday P 400 300 200 200 100 K 400 100 300 200 100 Assuming no setup or changeover time, determine the capacity requirements for each product and the total load for each of the three departments for each day of the 5-day workweek. 6. An air compressor assembly department has four employees who each work 40 hours a week. The processing time for assembling an air compressor is 3 hours. Given the information provided in the following table: 1. Determine the available capacity and develop a load profile for the air compressor assembly. blems related to capacity do you see, and what are YOL commendations to solve the problems? a Processing Load in Hours Available Capacity in Hours 0 comments Activity Page 1404 @ Type a comment 1 9:48 Cancel Text - operati...nd-edition.pdf ... requirements I were is a capacity uveriodu or under III duy ui ue work centers, what are some approaches you would take to level capacity? 4. Nerula Bakeries, a fictional bakery, has the following demand requirements for its specialty cakes in the month of June. Demand Requirements 100 Specialty Cake Graduation Cake Anniversary Cake Wedding Cake 70 50 The labor skill requirements for making specialty cakes are high, and the process involves two critical operationsbaking and decorating. The time required for each operation varies depending on the type of specialty cake. The standard labor hours per unit of skilled labor required for the three types of specialty cakes vary and are given in the following table: Standard Labor Hours per Unit for Each Operation Specialty Cake Baking Decorating Graduation Cake 1.0 2.0 3.0 Anniversary Cake Wedding Cake 6.0 9.0 5.0 Assuming an 8-hour work day with two shifts and 30 working days in the month of June, how many skilled workers would the bakery need to meet the demand requirements? If there is a capacity overload or underload in any of the work centers, what are some approaches you would take to level capacity? 5. The manufacturing sequence for two products that a company produces involves fabrication, assembly, and painting operations. Each operation requires 2 days to completely process a production lot before it can be moved to the next department. The processing times in hours per unit) for both products at each of the three departments in terms of both labor and machine resources are given in the following table: Painting Fabrication Assembly Labor Machine Labor Machine Labor Machine Product P2 2 1 1.5 Product K 2 1 2 1 1.5 0.5 The available labor and machine capacities at each department are 800 hours of labor and 600 hours for each day of a 5-day workweek. For the upcoming workweek, the company has developed the following production schedule for the two products. Friday Product Monday Tuesday Wednesday Thursday P 400 300 200 200 100 K 400 100 300 200 100 Assuming no setup or changeover time, determine the capacity requirements for each product and the total load for each of the three departments for each day of the 5-day workweek. 6. An air compressor assembly department has four employees who each work 40 hours a week. The processing time for assembling an air compressor is 3 hours. Given the information provided in the following table: 1. Determine the available capacity and develop a load profile for the air compressor assembly. blems related to capacity do you see, and what are YOL commendations to solve the problems? a Processing Load in Hours Available Capacity in Hours 0 comments Activity Page 1404 @ Type a comment 1Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock