Question: Please answer all the questions clearly A controller has been implemented to control a tractor mounted broadcast spreader. The spinner on the broadcast seeder is

Please answer all the questions clearly

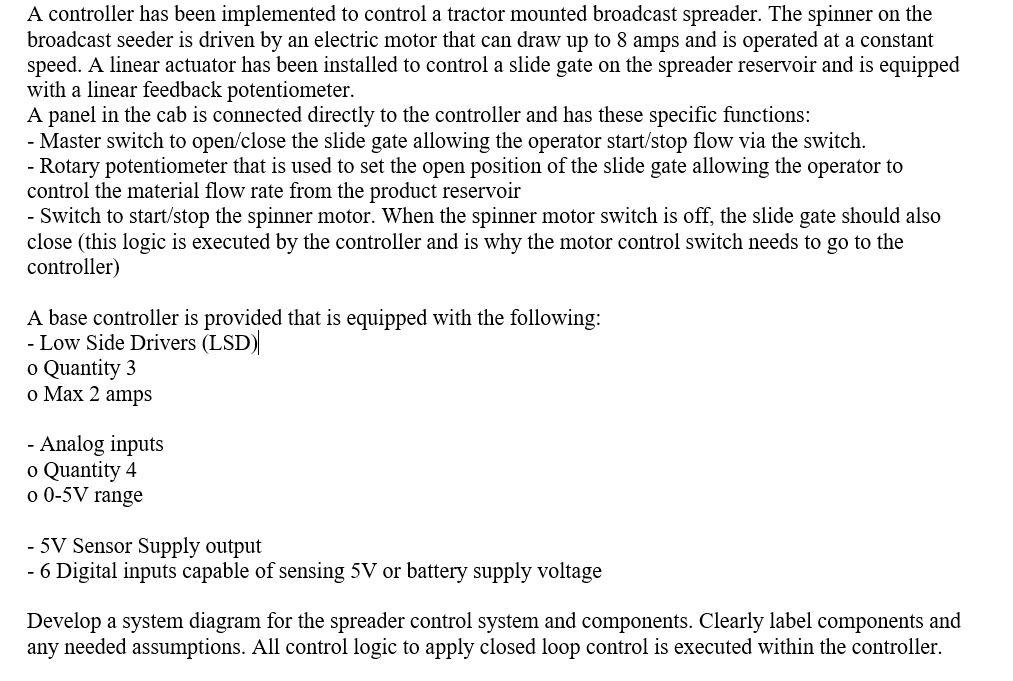

A controller has been implemented to control a tractor mounted broadcast spreader. The spinner on the broadcast seeder is driven by an electric motor that can draw up to 8 amps and is operated at a constant speed. A linear actuator has been installed to control a slide gate on the spreader reservoir and is equipped with a linear feedback potentiometer. A panel in the cab is connected directly to the controller and has these specific functions: - Master switch to open/close the slide gate allowing the operator start/stop flow via the switch. - Rotary potentiometer that is used to set the open position of the slide gate allowing the operator to control the material flow rate from the product reservoir - Switch to start/stop the spinner motor. When the spinner motor switch is off, the slide gate should also close (this logic is executed by the controller and is why the motor control switch needs to go to the controller) A base controller is provided that is equipped with the following: - Low Side Drivers (LSD) o Quantity 3 o Max 2 amps - Analog inputs o Quantity 4 o 0-5V range - 5V Sensor Supply output - 6 Digital inputs capable of sensing 5V or battery supply voltage Develop a system diagram for the spreader control system and components. Clearly label components and any needed assumptions. All control logic to apply closed loop control is executed within the controller. A controller has been implemented to control a tractor mounted broadcast spreader. The spinner on the broadcast seeder is driven by an electric motor that can draw up to 8 amps and is operated at a constant speed. A linear actuator has been installed to control a slide gate on the spreader reservoir and is equipped with a linear feedback potentiometer. A panel in the cab is connected directly to the controller and has these specific functions: - Master switch to open/close the slide gate allowing the operator start/stop flow via the switch. - Rotary potentiometer that is used to set the open position of the slide gate allowing the operator to control the material flow rate from the product reservoir - Switch to start/stop the spinner motor. When the spinner motor switch is off, the slide gate should also close (this logic is executed by the controller and is why the motor control switch needs to go to the controller) A base controller is provided that is equipped with the following: - Low Side Drivers (LSD) o Quantity 3 o Max 2 amps - Analog inputs o Quantity 4 o 0-5V range - 5V Sensor Supply output - 6 Digital inputs capable of sensing 5V or battery supply voltage Develop a system diagram for the spreader control system and components. Clearly label components and any needed assumptions. All control logic to apply closed loop control is executed within the controller

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts