Question: please answer all three parts different from others . Case Question Rocker Industries would like to evaluate level and chase demand strategies. Your report should

please answer all three parts different from others

.

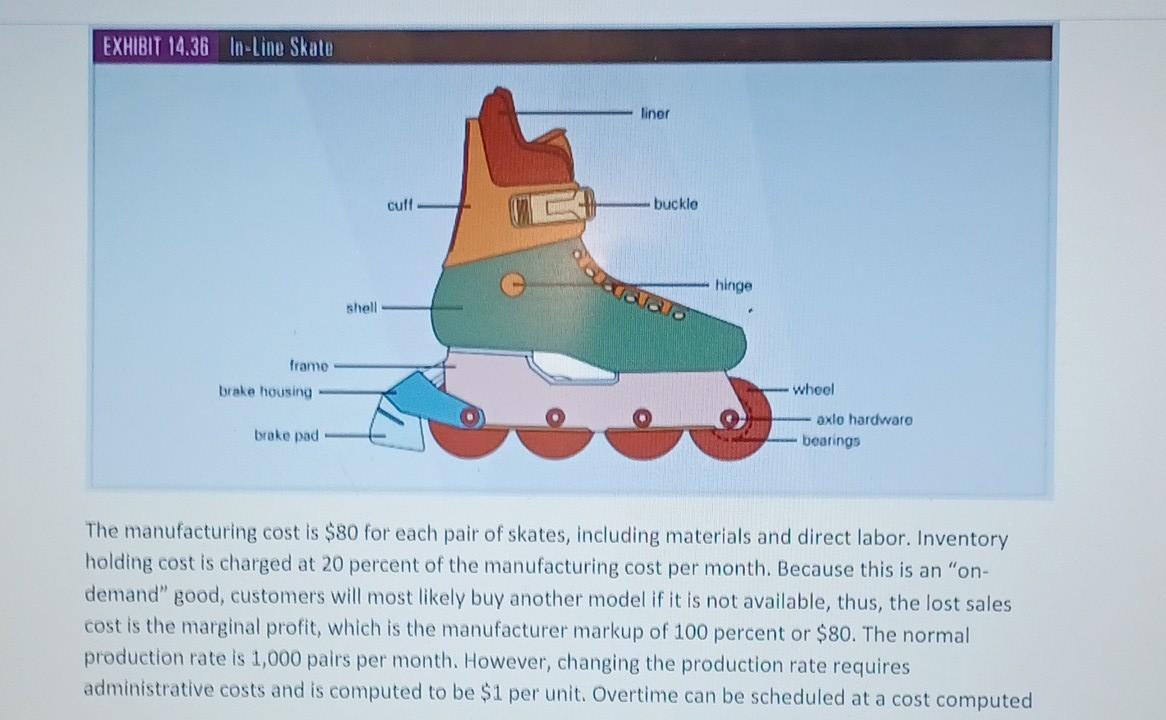

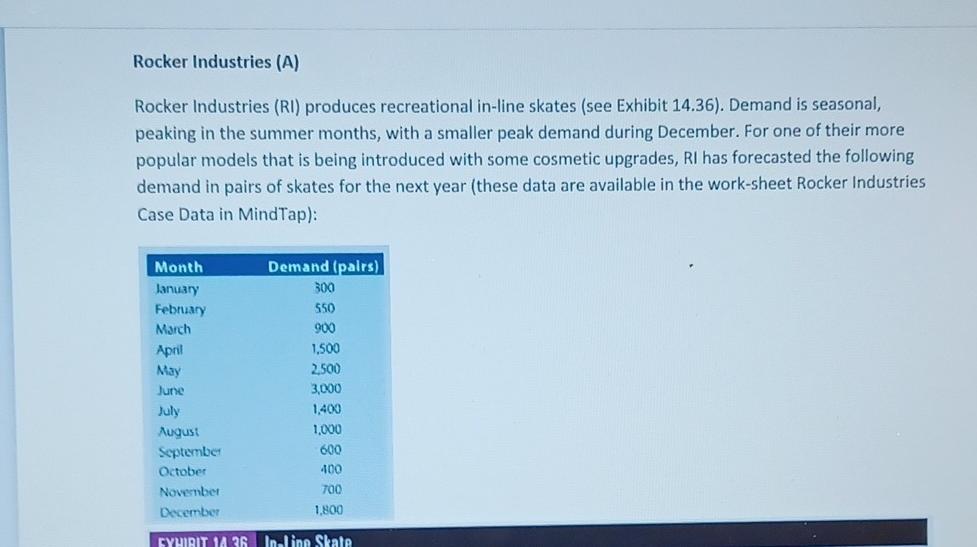

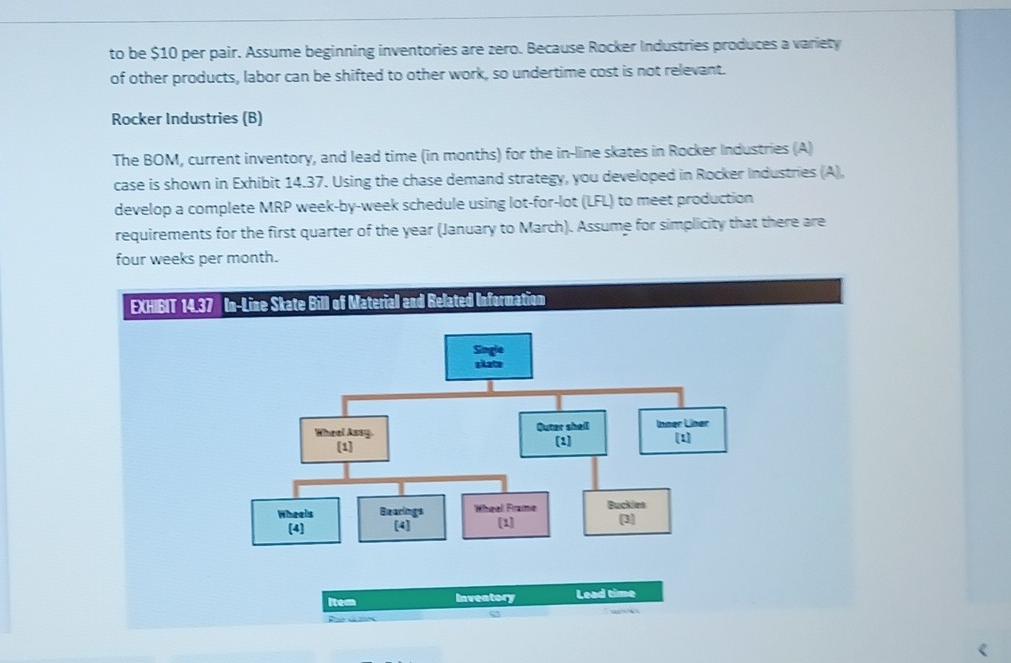

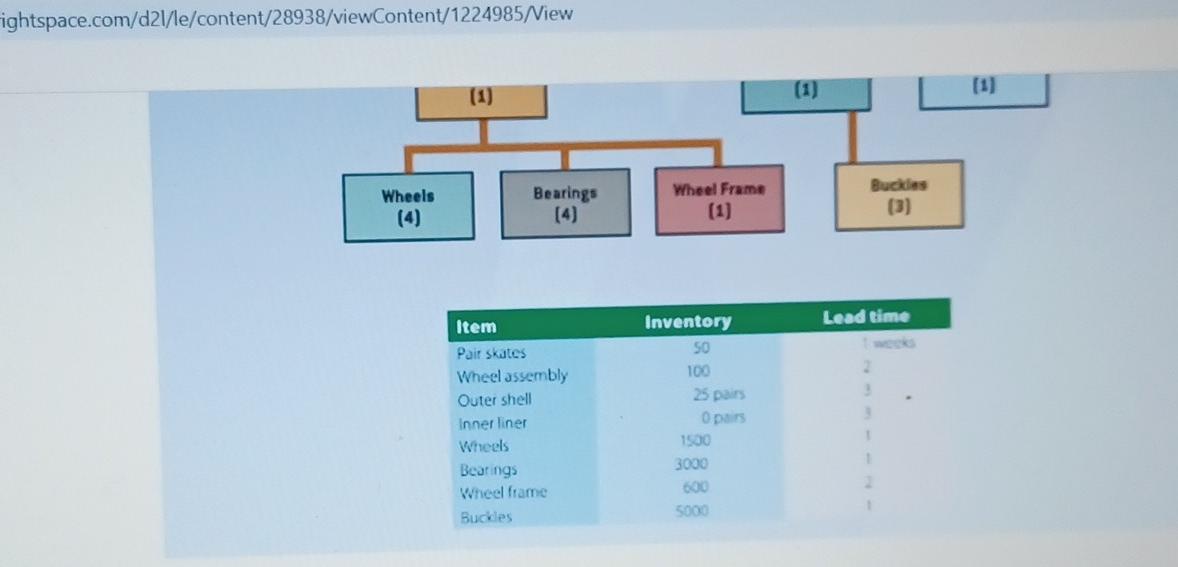

Case Question Rocker Industries would like to evaluate level and chase demand strategies. Your report should not only address financial impacts, but potential operational and managerial impacts of the different strategies. Case Question What are the cost and capacity implications from the planned schedule of order releases? Do you see any opportunities to use lot sizing to batch order quantities? Select one part and explain/justify. Analysis Students will provide their and feedback as to how they would have dealt with the issues/situation/challenge in the case study as if they were the operations manager of the EXHIBIT 14.36 In-Line Skate liner cult buckle hinge shell framo brake housing wheel brake pad axlo hardware bearings The manufacturing cost is $80 for each pair of skates, including materials and direct labor. Inventory holding cost is charged at 20 percent of the manufacturing cost per month. Because this is an "on- demand" good, customers will most likely buy another model if it is not available, thus, the lost sales cost is the marginal profit, which is the manufacturer markup of 100 percent or $80. The normal production rate is 1,000 pairs per month. However, changing the production rate requires administrative costs and is computed to be $1 per unit. Overtime can be scheduled at a cost computed Rocker Industries (A) Rocker Industries (RI) produces recreational in-line skates (see Exhibit 14.36). Demand is seasonal, peaking in the summer months, with a smaller peak demand during December. For one of their more popular models that is being introduced with some cosmetic upgrades, Rl has forecasted the following demand in pairs of skates for the next year (these data are available in the work-sheet Rocker Industries Case Data in MindTap): Month January Demand (palrs) 500 550 900 1.500 2,500 3,000 February March April May June July August September October November December 1,400 1.000 600 400 700 1,800 FYHIBIT 1436 In linn Skate to be $10 per pair. Assume beginning inventories are zero. Because Rocker Industries produces a variety of other products, labor can be shifted to other work, so undertime cost is not relevant Rocker Industries (6) The BOM, current inventory, and lead time (in months) for the in-line sketes in Rocker Industries (A) case is shown in Exhibit 14.37. Using the chase demand strategy, you developed in Rocker industries A. develop a complete MRP week-by-week schedule using lot-for-lot (LFL) to meet production requirements for the first quarter of the year (January to March). Assume for simplicity that there are four weeks per month EXHIBIT 14.37 In-Line Skate Bil of Material and Related laformation Sage Wheels (11 her her u (2) Wheels Buck Bearings Whal Prane Item Inventory Lead rightspace.com/d21/le/content/28938/viewContent/1224985/iew Wheel Frame Wheels (4) Bearings (4) Buckles (3) Lead time Item Pait skutes Wheel assembly Outer shell Inner liner Wheels Bearings Wheel frame Buckles Inventory 50 100 25 pairs Opers 1500 3000 600 5000

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock