Question: please answer and show work for 3.20. will give like for correct answer! 3.185. Material balances in batch processes: drying of soap with air It

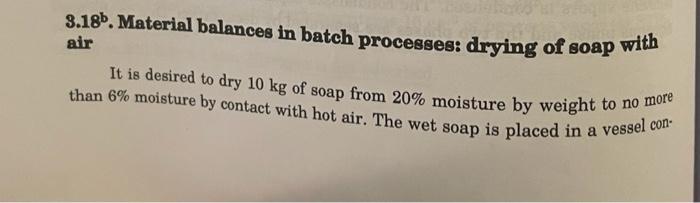

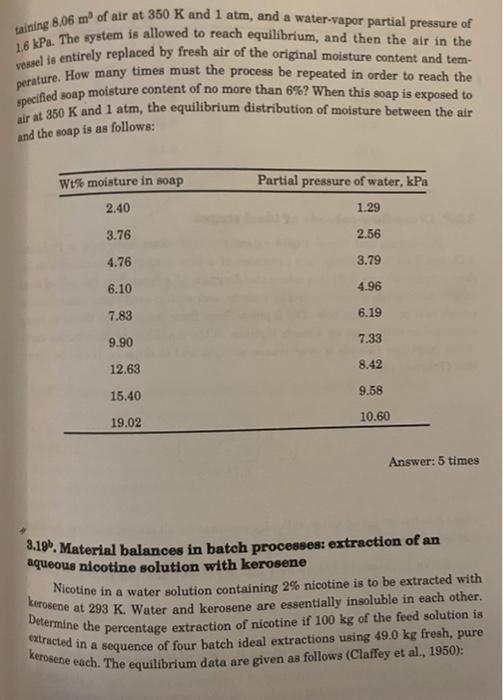

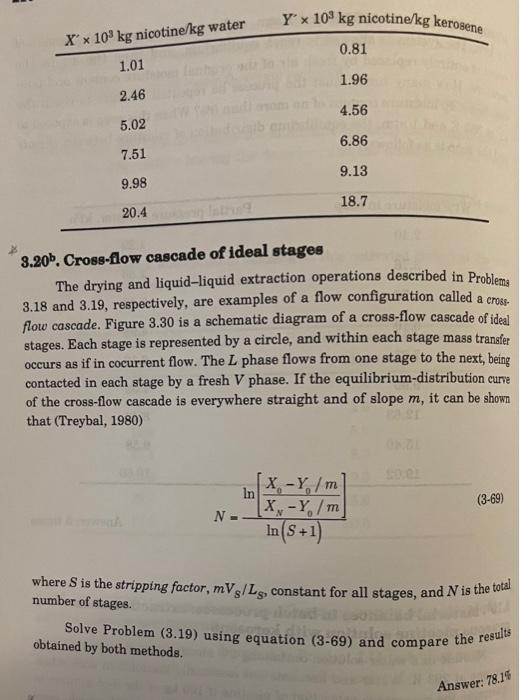

3.185. Material balances in batch processes: drying of soap with air It is desired to dry 10 kg of soap from 20% moisture by weight to no more than 6% moisture by contact with hot air. The wet soap is placed in a vessel con faining 8,06 m of air at 350 K and 1 atm, and a water-vapor partial pressure of 1.6 kPa. The system is allowed to reach equilibrium, and then the air in the vessel is entirely replaced by fresh air of the original moisture content and tem- perature. How many times must the process be repeated in order to reach the specified soap moisture content of no more than 6%? When this soap is exposed to air at 350 K and 1 atm, the equilibrium distribution of moisture between the air and the soap is as follows: Partial pressure of water, kPa wt% moisture in soap 2.40 1.29 3.76 2.56 4.76 3.79 6.10 4.96 7.83 6.19 9.90 7.33 12.63 8.42 15.40 9.58 19.02 10.60 Answer: 5 times 8.196. Material balances in batch processes: extraction of an aqueous nicotine solution with kerosene Nicotine in a water solution containing 2% nicotine is to be extracted with kerosene at 293 K. Water and kerosene are essentially insoluble in each other. Determine the percentage extraction of nicotine if 100 kg of the feed solution is extracted in a sequence of four batch ideal extractions using 49.0 kg fresh, pure kerosene each. The equilibrium data are given as follows (Claffey et al., 1950): X'* 109 kg nicotine/kg water Y x 104 kg nicotine/kg kerosene 0.81 1.01 1.96 2.46 4.56 5.02 6.86 7.51 9.13 9.98 18.7 20.4 3.205. Cross-flow cascade of ideal stages The drying and liquid-liquid extraction operations described in Probleme 3.18 and 3.19, respectively, are examples of a flow configuration called a crose flow cascade. Figure 3.30 is a schematic diagram of a cross-flow cascade of ideal stages. Each stage is represented by a circle, and within each stage mass transfer occurs as if in cocurrent flow. The L phase flows from one stage to the next, being contacted in each stage by a fresh V phase. If the equilibrium-distribution curve of the cross-flow cascade is everywhere straight and of slope m, it can be shown that (Treybal, 1980) m In (3-69) [X-r/m |X, Y, /m In(S+1) N where S is the stripping factor, mVg/Ls, constant for all stages, and N is the total number of stages. Solve Problem (3.19) using equation (3-69) and compare the results obtained by both methods. Answer: 78.14 3.185. Material balances in batch processes: drying of soap with air It is desired to dry 10 kg of soap from 20% moisture by weight to no more than 6% moisture by contact with hot air. The wet soap is placed in a vessel con faining 8,06 m of air at 350 K and 1 atm, and a water-vapor partial pressure of 1.6 kPa. The system is allowed to reach equilibrium, and then the air in the vessel is entirely replaced by fresh air of the original moisture content and tem- perature. How many times must the process be repeated in order to reach the specified soap moisture content of no more than 6%? When this soap is exposed to air at 350 K and 1 atm, the equilibrium distribution of moisture between the air and the soap is as follows: Partial pressure of water, kPa wt% moisture in soap 2.40 1.29 3.76 2.56 4.76 3.79 6.10 4.96 7.83 6.19 9.90 7.33 12.63 8.42 15.40 9.58 19.02 10.60 Answer: 5 times 8.196. Material balances in batch processes: extraction of an aqueous nicotine solution with kerosene Nicotine in a water solution containing 2% nicotine is to be extracted with kerosene at 293 K. Water and kerosene are essentially insoluble in each other. Determine the percentage extraction of nicotine if 100 kg of the feed solution is extracted in a sequence of four batch ideal extractions using 49.0 kg fresh, pure kerosene each. The equilibrium data are given as follows (Claffey et al., 1950): X'* 109 kg nicotine/kg water Y x 104 kg nicotine/kg kerosene 0.81 1.01 1.96 2.46 4.56 5.02 6.86 7.51 9.13 9.98 18.7 20.4 3.205. Cross-flow cascade of ideal stages The drying and liquid-liquid extraction operations described in Probleme 3.18 and 3.19, respectively, are examples of a flow configuration called a crose flow cascade. Figure 3.30 is a schematic diagram of a cross-flow cascade of ideal stages. Each stage is represented by a circle, and within each stage mass transfer occurs as if in cocurrent flow. The L phase flows from one stage to the next, being contacted in each stage by a fresh V phase. If the equilibrium-distribution curve of the cross-flow cascade is everywhere straight and of slope m, it can be shown that (Treybal, 1980) m In (3-69) [X-r/m |X, Y, /m In(S+1) N where S is the stripping factor, mVg/Ls, constant for all stages, and N is the total number of stages. Solve Problem (3.19) using equation (3-69) and compare the results obtained by both methods. Answer: 78.14

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts