Question: please answer asap! will give thumbs up 12. Studies on a machine that molds plastic water pipe indicate that when it is injecting 1-inch diameter

please answer asap! will give thumbs up

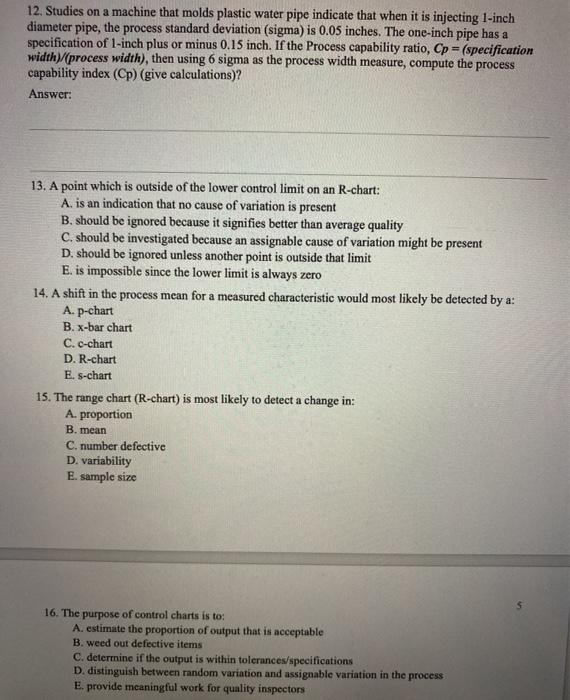

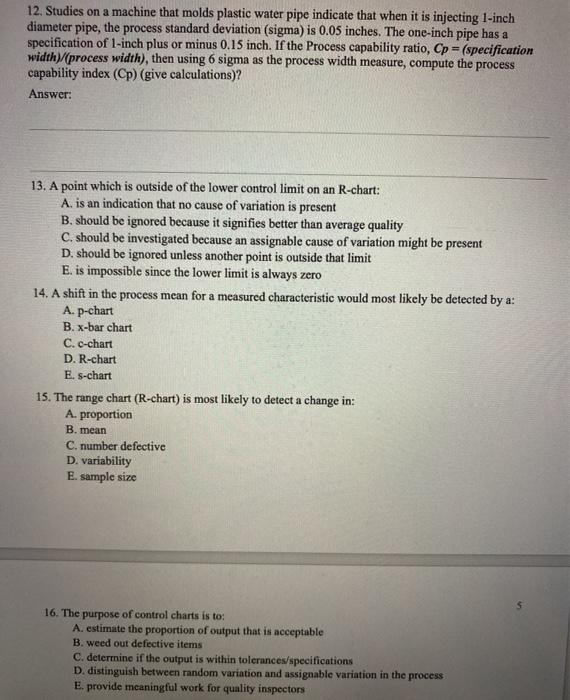

12. Studies on a machine that molds plastic water pipe indicate that when it is injecting 1-inch diameter pipe, the process standard deviation (sigma) is 0.05 inches. The one-inch pipe has a specification of 1-inch plus or minus 0.15 inch. If the Process capability ratio, Cp = (specification width)/(process width), then using 6 sigma as the process width measure, compute the process capability index (Cp) (give calculations)? Answer: 13. A point which is outside of the lower control limit on an R-chart: A. is an indication that no cause of variation is present B. should be ignored because it signifies better than average quality C. should be investigated because an assignable cause of variation might be present D. should be ignored unless another point is outside that limit E. is impossible since the lower limit is always zero 14. A shift in the process mean for a measured characteristic would most likely be detected by a: A. p-chart B. x-bar chart C. c-chart D. R-chart E.s-chart 15. The range chart (R-chart) is most likely to detect a change in: A. proportion B. mean C. number defective D. variability E. sample size 16. The purpose of control charts is to: A. estimate the proportion of output that is acceptable B. weed out defective items C. determine if the output is within tolerances/specifications D. distinguish between random variation and assignable variation in the process E. provide meaningful work for quality inspectors

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock