Question: please answer asap You are Chief Engineer for a Municipal Utility Authority (MUA) responsible for decisions related to investment and operation at the MUA's Water

please answer asap

please answer asap

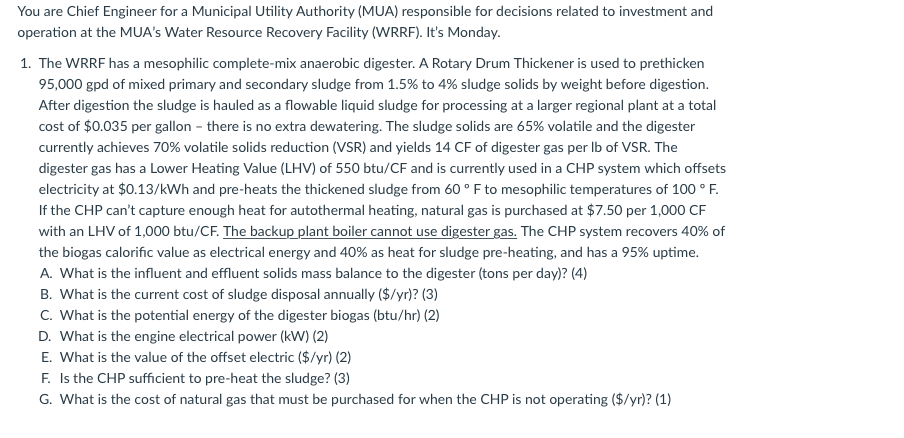

You are Chief Engineer for a Municipal Utility Authority (MUA) responsible for decisions related to investment and operation at the MUA's Water Resource Recovery Facility (WRRF). It's Monday. 1. The WRRF has a mesophilic complete-mix anaerobic digester. A Rotary Drum Thickener is used to prethicken 95,000 gpd of mixed primary and secondary sludge from 1.5% to 4% sludge solids by weight before digestion. After digestion the sludge is hauled as a flowable liquid sludge for processing at a larger regional plant at a total cost of $0.035 per gallon - there is no extra dewatering. The sludge solids are 65% volatile and the digester currently achieves 70% volatile solids reduction (VSR) and yields 14 CF of digester gas per lb of VSR. The digester gas has a Lower Heating Value (LHV) of 550 btu/CF and is currently used in a CHP system which offsets electricity at $0.13/kWh and pre-heats the thickened sludge from 60 F to mesophilic temperatures of 100 F. If the CHP can't capture enough heat for autothermal heating, natural gas is purchased at $7.50 per 1,000 CF with an LHV of 1,000 btu/CF. The backup plant boiler cannot use digester gas. The CHP system recovers 40% the biogas calorific value as electrical energy and 40% as heat for sludge pre-heating, and has a 95% uptime. A. What is the influent and effluent solids mass balance to the digester (tons per day)? (4) B. What is the current cost of sludge disposal annually ($/yr)? (3) C. What is the potential energy of the digester biogas (btu/hr) (2) D. What is the engine electrical power (kW) (2) E. What is the value of the offset electric ($/yr) (2) F. Is the CHP sufficient to pre-heat the sludge? (3) G. What is the cost of natural gas that must be purchased for when the CHP is not operating ($/yr)? (1) You are Chief Engineer for a Municipal Utility Authority (MUA) responsible for decisions related to investment and operation at the MUA's Water Resource Recovery Facility (WRRF). It's Monday. 1. The WRRF has a mesophilic complete-mix anaerobic digester. A Rotary Drum Thickener is used to prethicken 95,000 gpd of mixed primary and secondary sludge from 1.5% to 4% sludge solids by weight before digestion. After digestion the sludge is hauled as a flowable liquid sludge for processing at a larger regional plant at a total cost of $0.035 per gallon - there is no extra dewatering. The sludge solids are 65% volatile and the digester currently achieves 70% volatile solids reduction (VSR) and yields 14 CF of digester gas per lb of VSR. The digester gas has a Lower Heating Value (LHV) of 550 btu/CF and is currently used in a CHP system which offsets electricity at $0.13/kWh and pre-heats the thickened sludge from 60 F to mesophilic temperatures of 100 F. If the CHP can't capture enough heat for autothermal heating, natural gas is purchased at $7.50 per 1,000 CF with an LHV of 1,000 btu/CF. The backup plant boiler cannot use digester gas. The CHP system recovers 40% the biogas calorific value as electrical energy and 40% as heat for sludge pre-heating, and has a 95% uptime. A. What is the influent and effluent solids mass balance to the digester (tons per day)? (4) B. What is the current cost of sludge disposal annually ($/yr)? (3) C. What is the potential energy of the digester biogas (btu/hr) (2) D. What is the engine electrical power (kW) (2) E. What is the value of the offset electric ($/yr) (2) F. Is the CHP sufficient to pre-heat the sludge? (3) G. What is the cost of natural gas that must be purchased for when the CHP is not operating ($/yr)? (1)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts