Question: Please answer me with a clear & detailed steps: Question 3 (20 marks] At Ross White's machine shop, total demand of brackets at is known

Please answer me with a clear & detailed steps:

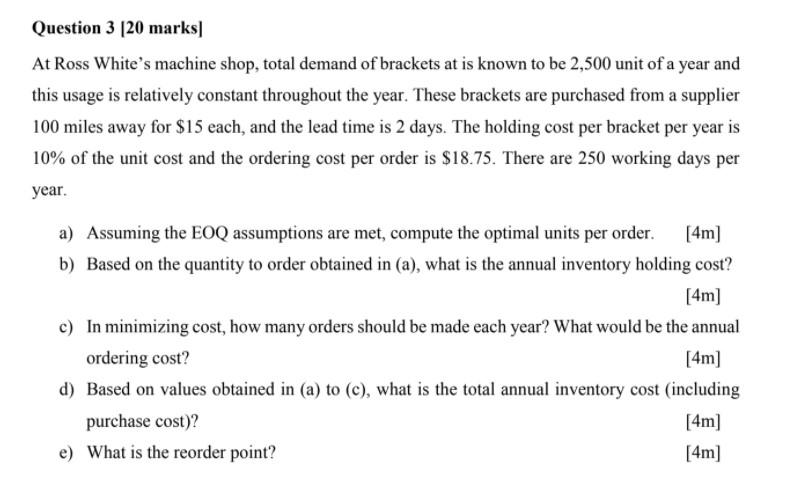

Question 3 (20 marks] At Ross White's machine shop, total demand of brackets at is known to be 2,500 unit of a year and this usage is relatively constant throughout the year. These brackets are purchased from a supplier 100 miles away for $15 each, and the lead time is 2 days. The holding cost per bracket per year is 10% of the unit cost and the ordering cost per order is $18.75. There are 250 working days per year. a) Assuming the EOQ assumptions are met, compute the optimal units per order. [4m) b) Based on the quantity to order obtained in (a), what is the annual inventory holding cost? [4m] C) In minimizing cost, how many orders should be made each year? What would be the annual ordering cost? [4m) d) Based on values obtained in (a) to (c), what is the total annual inventory cost (including purchase cost)? [4m) e) What is the reorder point? [4m) Question 3 (20 marks] At Ross White's machine shop, total demand of brackets at is known to be 2,500 unit of a year and this usage is relatively constant throughout the year. These brackets are purchased from a supplier 100 miles away for $15 each, and the lead time is 2 days. The holding cost per bracket per year is 10% of the unit cost and the ordering cost per order is $18.75. There are 250 working days per year. a) Assuming the EOQ assumptions are met, compute the optimal units per order. [4m) b) Based on the quantity to order obtained in (a), what is the annual inventory holding cost? [4m] C) In minimizing cost, how many orders should be made each year? What would be the annual ordering cost? [4m) d) Based on values obtained in (a) to (c), what is the total annual inventory cost (including purchase cost)? [4m) e) What is the reorder point? [4m)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts