Question: please answer question C. Q5 20 Marks (a) As a part of lean production and Just-In-Time (JIT) implementation, it requires to minimize the setup time.

please answer question C.

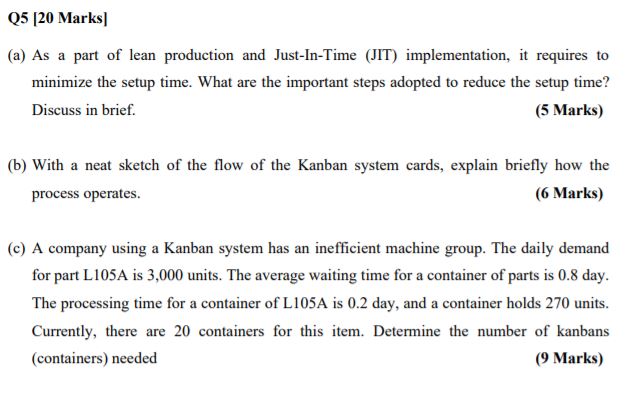

Q5 20 Marks (a) As a part of lean production and Just-In-Time (JIT) implementation, it requires to minimize the setup time. What are the important steps adopted to reduce the setup time? Discuss in brief. (5 Marks) (b) With a neat sketch of the flow of the Kanban system cards, explain briefly how the process operates. (6 Marks) (c) A company using a Kanban system has an inefficient machine group. The daily demand for part L105A is 3,000 units. The average waiting time for a container of parts is 0.8 day. The processing time for a container of L105A is 0.2 day, and a container holds 270 units. Currently, there are 20 containers for this item. Determine the number of kanbans (containers) needed (9 Marks)Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock