Question: Please answer questions 1 and 2(a)(b)(c). CASE STUDY: WORKFLOW PLANNING Instruction Review the forecast data below. The Change Schedule identifies the different nodes across the

Please answer questions 1 and 2(a)(b)(c).

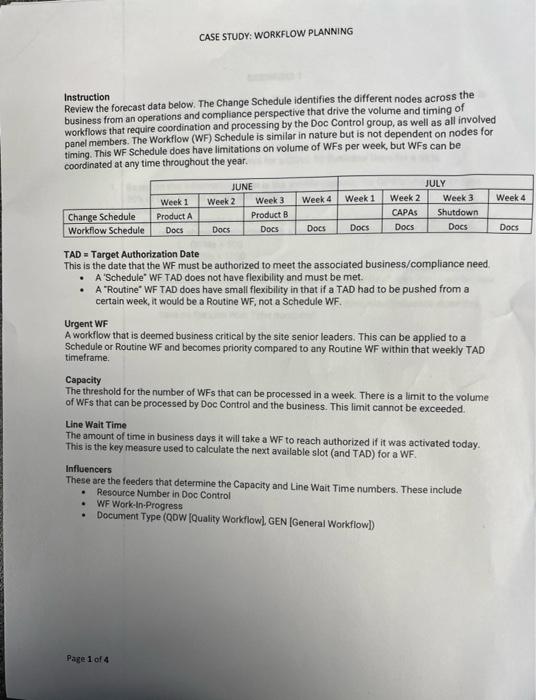

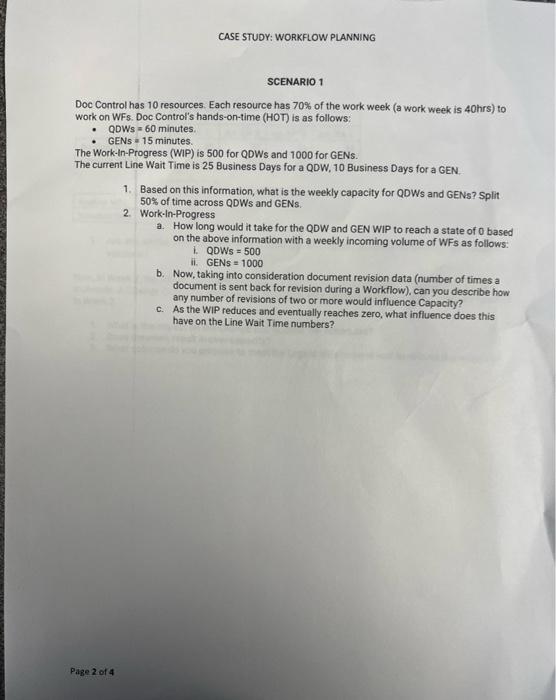

CASE STUDY: WORKFLOW PLANNING Instruction Review the forecast data below. The Change Schedule identifies the different nodes across the business from an operations and compliance perspective that drive the volume and timing of workflows that require coordination and processing by the Doc Control group, as well as all involved panel members. The Workflow (WF) Schedule is similar in nature but is not dependent on nodes for timing. This WF Schedule does have limitations on volume of WFs per week, but WFs can be coordinated at any time throughout the year. Week 4 Week 1 Week 4 Week 1 Product A Docs JUNE Week 2 Week 3 Product B Docs Docs JULY Week 2 Week 3 CAPAS Shutdown Docs Docs Docs Docs Docs Change Schedule Workflow Schedule TAD - Target Authorization Date This is the date that the WF must be authorized to meet the associated business/compliance need A'Schedule WF TAD does not have flexibility and must be met. A "Routine WF TAD does have small flexibility in that if a TAD had to be pushed from a certain week, it would be a Routine WF, not a Schedule WF. Urgent WF A workflow that is deemed business critical by the site senior leaders. This can be applied to a Schedule or Routine WF and becomes priority compared to any Routine WF within that weekly TAD timeframe Capacity The threshold for the number of WFs that can be processed in a week. There is a limit to the volume of WFs that can be processed by Doc Control and the business. This limit cannot be exceeded. Line Wait Time The amount of time in business days it will take a WF to reach authorized if it was activated today. This is the key measure used to calculate the next available slot (and TAD) for a WF. Influencers These are the feeders that determine the Capacity and Line Wait Time numbers. These include Resource Number in Doc Control WE Work-In-Progress Document Type (QOW (Quality Workflow). GEN (General Workflow) Page 1 of 4 CASE STUDY: WORKFLOW PLANNING SCENARIO 1 Doc Control has 10 resources. Each resource has 70% of the work week (a work week is 40hrs) to work on WFs. Doc Control's hands-on-time (HOT) is as follows: QDWS - 60 minutes. GENS - 15 minutes The Work-In-Progress (WIP) is 500 for QDWs and 1000 for GENS. The current Line Wait Time is 25 Business Days for a QDW, 10 Business Days for a GEN 1. Based on this information, what is the weekly capacity for QDWs and GENS? Split 50% of time across QDWs and GENS. 2. Work-In-Progress a. How long would it take for the QDW and GEN WIP to reach a state of O based on the above information with a weekly incoming volume of WFs as follows: L QDWs = 500 ii. GENs = 1000 b. Now, taking into consideration document revision data (number of times a document is sent back for revision during a Workflow), can you describe how any number of revisions of two or more would influence Capacity? c. As the WIP reduces and eventually reaches zero, what influence does this have on the Line Wait Time numbers? Page 2 of 4

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock