Question: Please, answer the four questions and show work. Design specifications require that a critical dimension on a product measure 25025 units. A process considered for

Please, answer the four questions and show work.

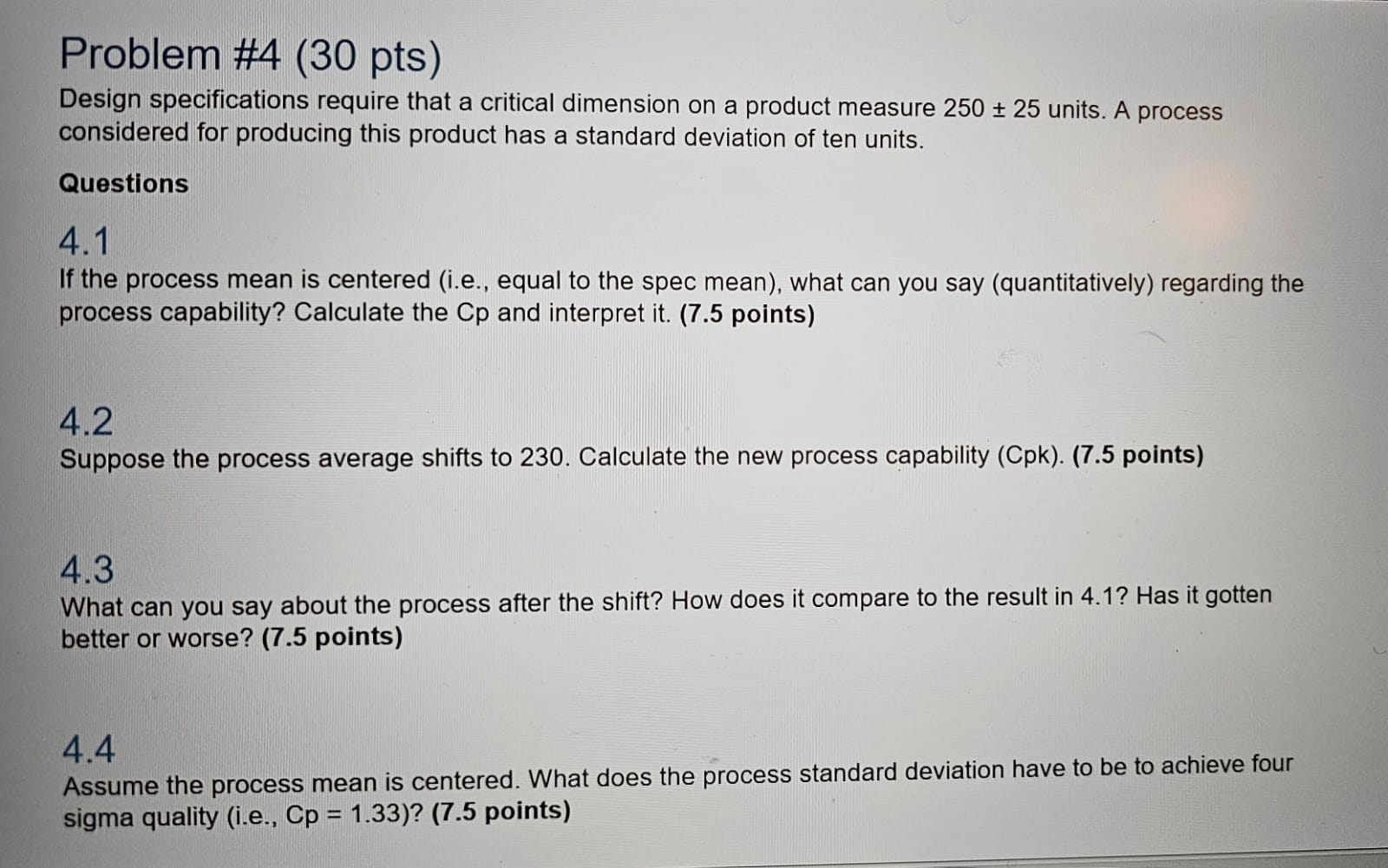

Design specifications require that a critical dimension on a product measure 25025 units. A process considered for producing this product has a standard deviation of ten units. Questions 4.1 If the process mean is centered (i.e., equal to the spec mean), what can you say (quantitatively) regarding the process capability? Calculate the Cp and interpret it. (7.5 points) 4.2 Suppose the process average shifts to 230 . Calculate the new process capability (Cpk). (7.5 points) 4.3 What can you say about the process after the shift? How does it compare to the result in 4.1? Has it gotten better or worse? (7.5 points) 4.4 Assume the process mean is centered. What does the process standard deviation have to be to achieve four sigma quality (i.e., Cp=1.33) ? (7.5 points)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts