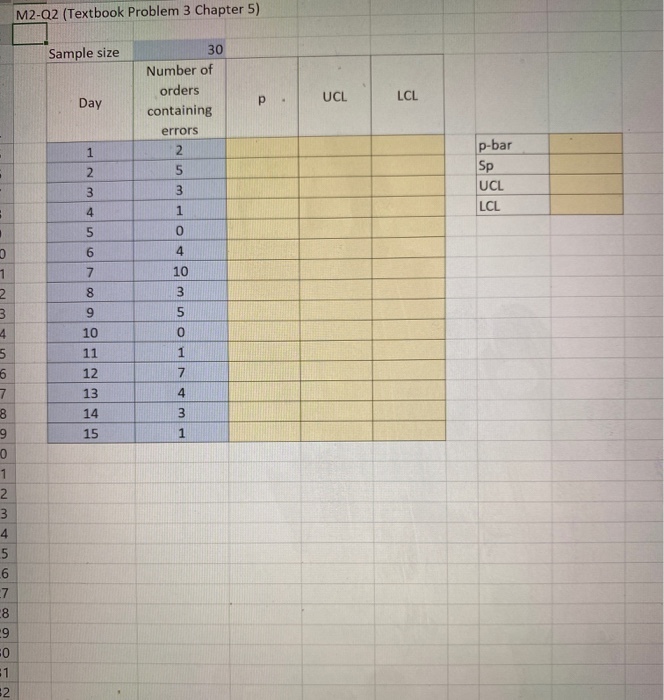

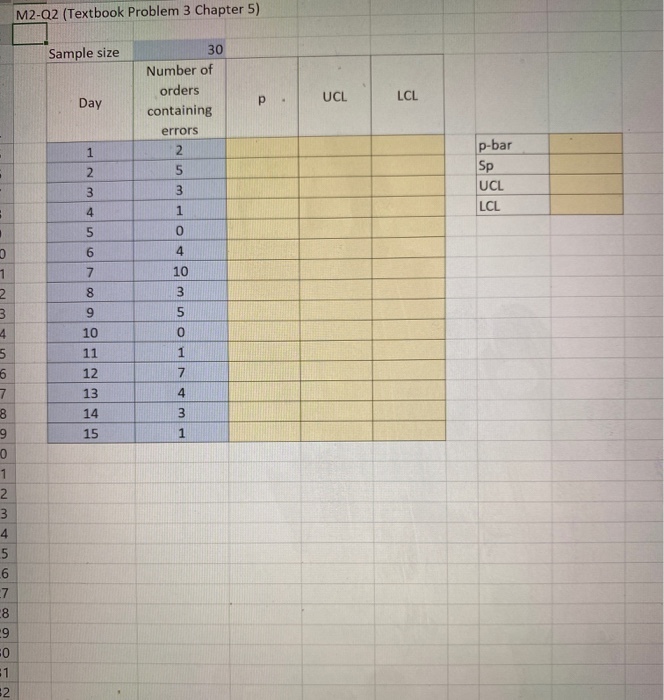

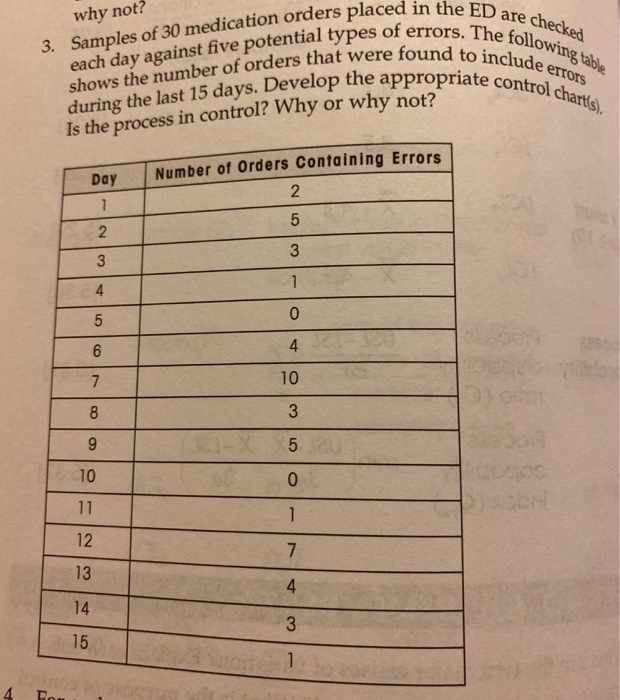

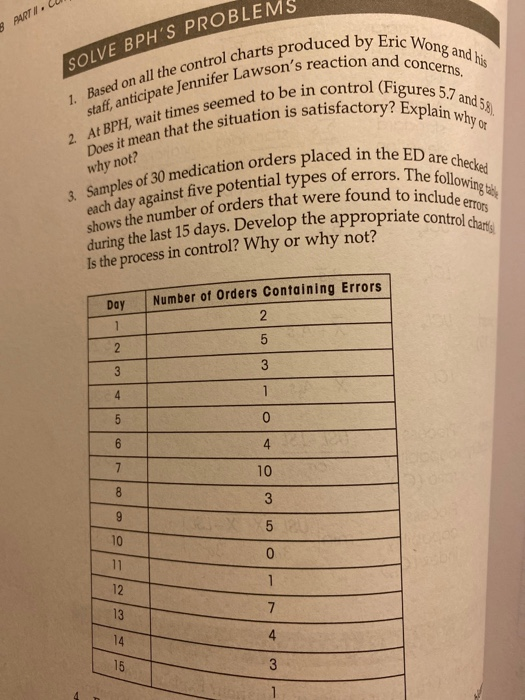

Question: Please assist with below. Please go step by step to explain process. M2-Q2 (Textbook Problem 3 Chapter 5) Sample size 30 Number of orders containing

Please assist with below. Please go step by step to explain process.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock