Question: ( please calculate by hand no excel ) Question 2 . Material Requirements Planning ( 2 5 marks ) The MRP gross requirements for product

please calculate by hand no excel

Question Material Requirements Planning marks

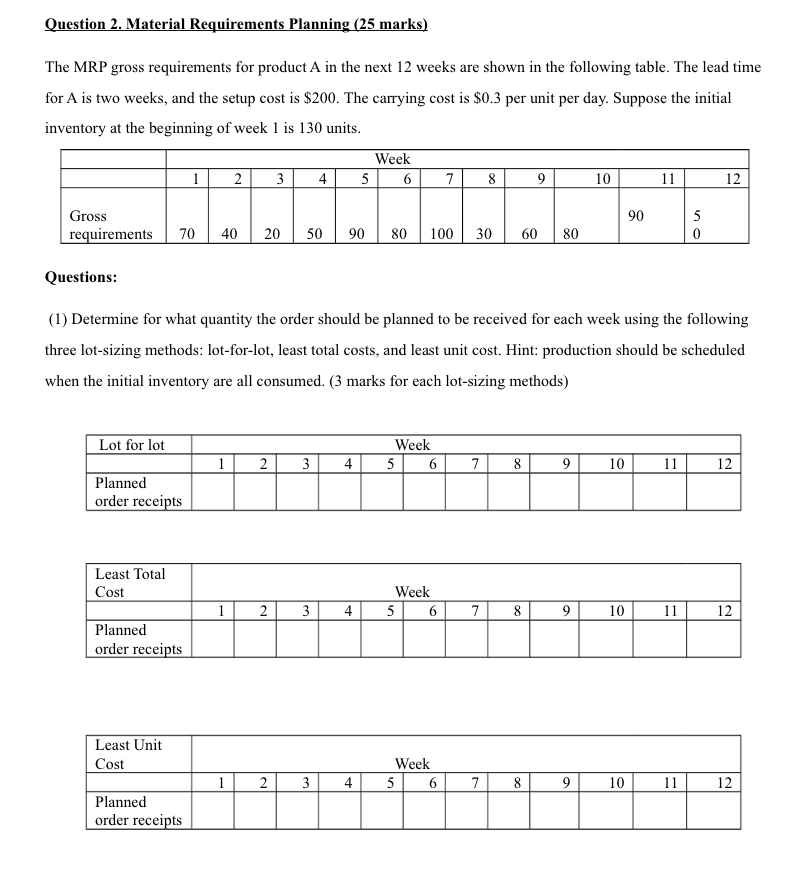

The MRP gross requirements for product A in the next weeks are shown in the following table. The lead time

for A is two weeks, and the setup cost is $ The carrying cost is $ per unit per day. Suppose the initial

inventory at the beginning of week is units.

Questions:

Determine for what quantity the order should be planned to be received for each week using the following

three lotsizing methods: lotforlot, least total costs, and least unit cost. Hint: production should be scheduled

when the initial inventory are all consumed. marks for each lotsizing methods

The product structure diagram for producing item A is given as follows.

The beginning inventory in week for item B and C are units and units respectively. The lead time for

both item B and item C is one week. There are units of item B scheduled to be received at the beginning of

week and units of item C scheduled to be received at the beginning of week

Suppose A is produced based on the lotforlot method, and B and C are produced in batches with a fixed batch

size of units and units respectively. Complete the MRP schedule for AB and C in the following tables.

marks for A; marks for B; marks for C

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock