Question: discuss the case study, Improving Production at Beothic Fish , focusing on the following elements of the case: Identify the problem Diagnose the cause(s)

discuss the case study, Improving Production at Beothic Fish, focusing on the following elements of the case:

- Identify the problem

- Diagnose the cause(s)

- The case study indicates that the general manager plans on reorganizing the floor plan of the plant. Offer your recommendations on how to reorganize the floor plan. Please also offer what metrics should be used to determine if the reorganized floor plan is effective.

-

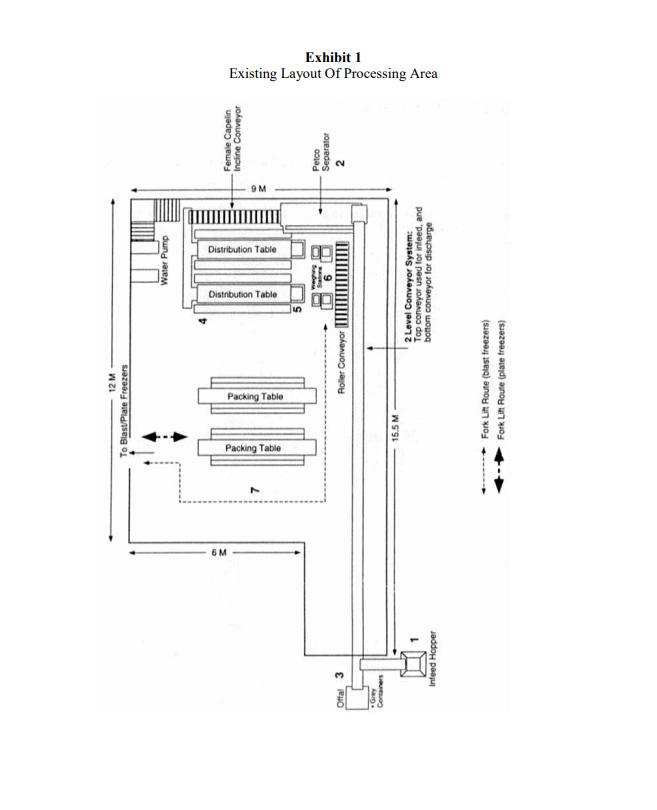

PETCO 3500 Fish Grading Machine Improving Production At Beothic Fish Processors Ltd. "The Pelagic processing area at the plant in Valleyfield, Newfoundland, has not worked out as well as we had hoped for processing capelin," identified the General Manager of Beothic Fish Processors Ltd. "Although the company continues to be very successful, if we are to offer competitive prices and still earn a profit we must keep our production costs as low as possible, and given that production costs are a function of production efficiency, it is imperative that we improve our present production system. It appears to me that we must look carefully at our existing plant layout to accomplish this." Company Background Beothic Fish Processors Ltd. (Beothic) was one of the largest processors of pelagic (capelin, mackerel and herring) fish species in Newfoundland and Labrador, with capelin being, by far, the primary species. Although the company began in 1967, it was not until 1979, when a modern cold storage facility was constructed at Valleyfield, and new blast freezers were installed, that the company was able to handle capelin. By 1989, capelin was a major contributor to Beothic's overall profitability. By Newfoundland standards, capelin processing was a relatively new fishery, having been developed about thirty years ago. Originally, capelin were sorted by hand, however, it proved impossible to handle the enormous quantities demanded by the market in this manner. The industry soon turned to the use of mechanical sorters which, although not perfect, were able to process large quantities quickly and at relatively low cost. The Present Production System The capelin processing facilities at Beothic are illustrated in Exhibit 1. Capelin entered the system via a water-filled infeed hopper, labelled as 1 on the exhibit. At this point, the insulated containers used for transport were simply emptied into the hopper. They then proceeded along a conveyor belt to the mechanical separator -- a Petco 3500 (2). The separator consisted of a series of ribbed slots, which gradually increased in size, that the capelin were shaken across. The very small capelin fell out first, and were conveyed back to the offal area where the unusable portion of the raw material was collected (3). The intermediate sized capelin, which were the marketable females, fell through next, and were conveyed to the distribution tables (4). The capelin, which were primarily male, proceeded to the end of the separator and joined the small females on the conveyor as offal. At each distribution table, which was actually a conveyor, approximately 18 workers removed by hand

Step by Step Solution

3.63 Rating (150 Votes )

There are 3 Steps involved in it

The case study Improving Production at Beothic Fish Processors Ltd describes the challenges faced by a fish processing company in Newfoundland Canada The company is looking to improve its production e... View full answer

Get step-by-step solutions from verified subject matter experts