Question: Please do the solution step by step Think that you are working for a factory which produces aliminum soda cans as shown in left. Your

Please do the solution step by step

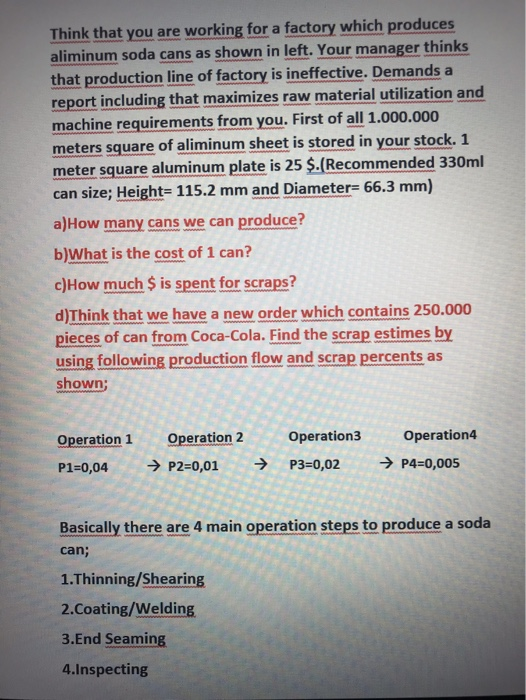

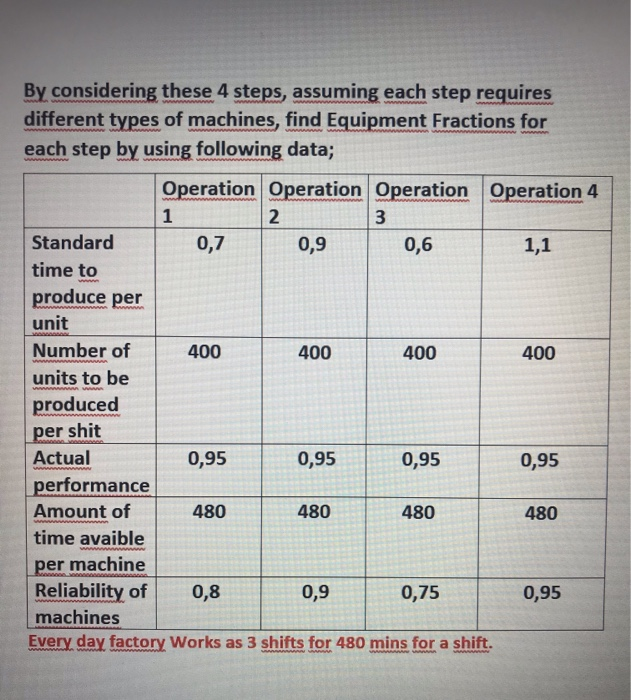

Think that you are working for a factory which produces aliminum soda cans as shown in left. Your manager thinks that production line of factory is ineffective. Demands a report including that maximizes raw material utilization and machine requirements from you. First of all 1.000.000 meters square of aliminum sheet is stored in your stock. 1 meter square aluminum plate is 25 $.(Recommended 330ml can size; Height= 115.2 mm and Diameter=66.3 mm) a)How many cans we can produce? b)What is the cost of 1 can? c)How much $ is spent for scraps? d)Think that we have a new order which contains 250.000 pieces of can from Coca-Cola. Find the scrap estimes by using following production flow and scrap percents as shown; Operation 1 Operation 2 Operation 3 P3=0,02 Operation 4 P4=0,005 P1=0,04 P2=0,01 Basically there are 4 main operation steps to produce a soda can; 1.Thinning/Shearing 2.Coating/Welding 3.End Seaming 4.Inspecting By considering these 4 steps, assuming each step requires different types of machines, find Equipment Fractions for each step by using following data; Operation Operation Operation Operation 4 1 2 3 Standard 0,7 0,9 0,6 1,1 time to produce per unit Number of 400 400 400 400 units to be produced per shit Actual 0,95 0,95 0,95 0,95 performance Amount of 480 480 480 480 time avaible per machine Reliability of 0,8 0,9 0,75 0,95 machines Every day factory Works as 3 shifts for 480 mins for a shift. WAR WARN Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock