Question: Please explain answers and not just post numbers. I am not understanding the math and where the numbers come from for the calculations. Thank you.

Please explain answers and not just post numbers. I am not understanding the math and where the numbers come from for the calculations. Thank you.

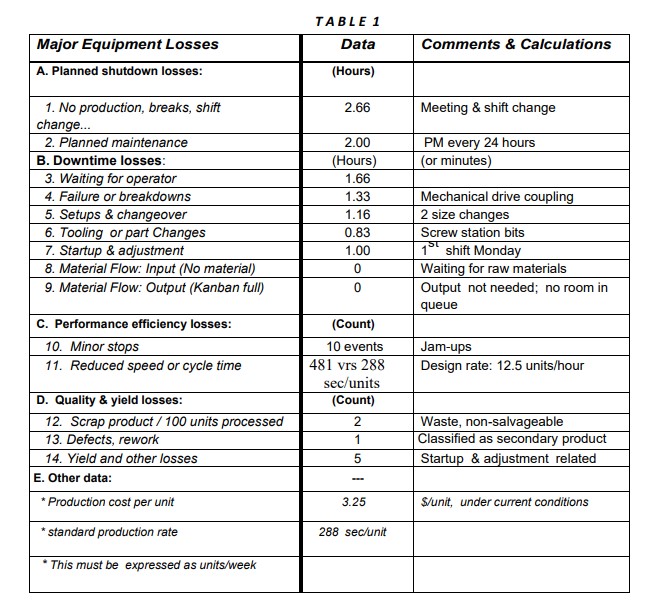

The Alcorn Fabrication Company has embarked on an aggressive TPM project to cut maintenance cost, improve productivity, and shorten manufacturing lead times. One of the initial steps in the project, involves determining the current Overall Equipment Efficiency (OEE) on their primary slitting machines. The data shown in Table 1, was recently collected during 24 hours of continuous observation of several slitting machines. Note that the data represent average time for each element per machine. The Alcorn Company operates their plant on a 5 days/week, 3 shifts per day schedule: Determine: 1. Overall equipment efficiency for each slitter 2. Actual production rate per hour under the current conditions. 3. Total manufacturing lead time (MLT) for a customer order size of 8500 units. 4. As the manager of the TPM project, determine by what \% current OEE could be improved. By what percentage manufacturing lead time is improved? 5. Using your answer in "4", estimate \% improvement in Machine capacity* and production cost/unit. TABLE 1

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts