Question: please explain how they got the answers for seperate vs joint ordering. how did they work out material costs, order cost, holding cost, cycle inventory

please explain how they got the answers for seperate vs joint ordering. how did they work out material costs, order cost, holding cost, cycle inventory and average flow time for both categories. many thanks

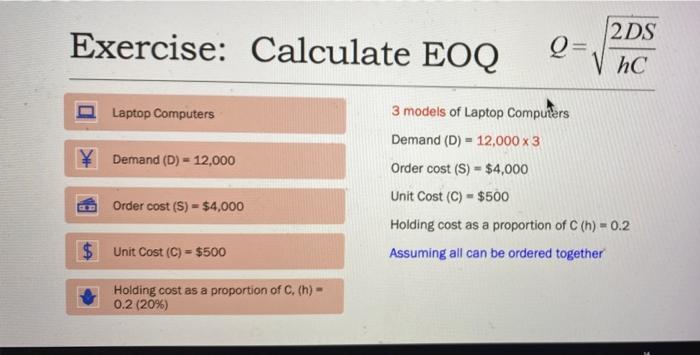

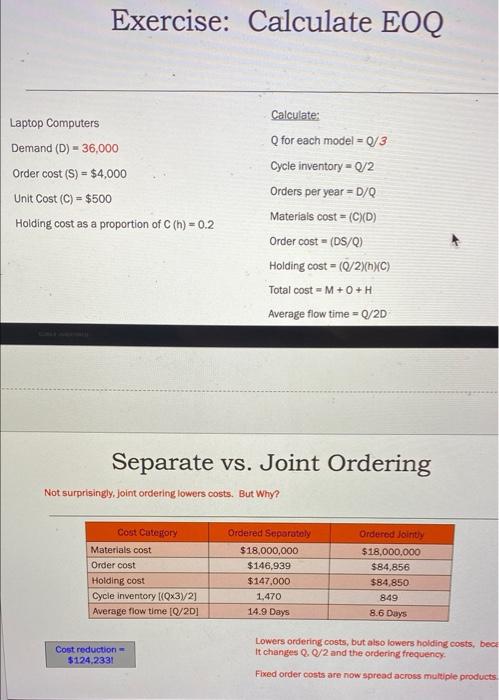

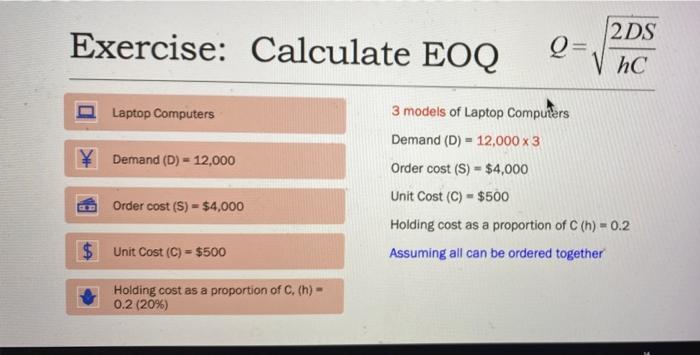

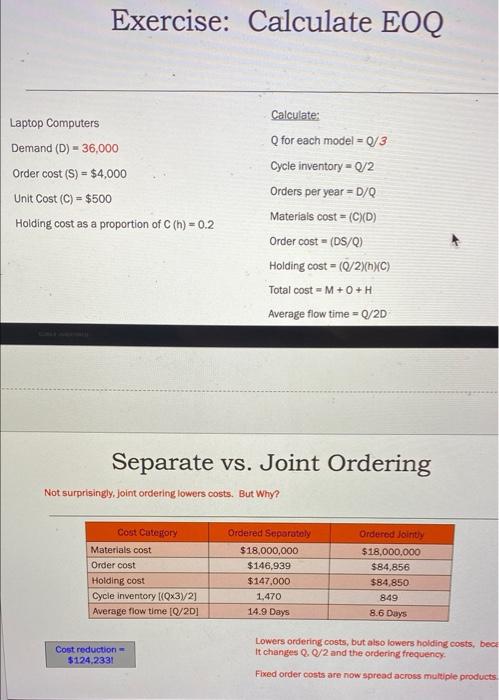

Exercise: Calculate EOQ 2DS Q= V hC Laptop Computers Demand (D) - 12,000 3 models of Laptop Computers Demand (D) = 12,000 x 3 Order cost (S) - $4,000 Unit Cost (C) - $500 Holding cost as a proportion of C (h) = 0.2 Assuming all can be ordered together Order cost (S) - $4,000 Unit Cost (C) = $500 Holding cost as a proportion of C. (h) - 0.2 (20%) Exercise: Calculate EOQ Laptop Computers Demand (D) - 36,000 Order cost (S) = $4,000 Unit Cost (C) = $500 Holding cost as a proportion of C (h) = 0.2 Calculate: Q for each model = 0/3 Cycle inventory = 0/2 Orders per year=D/Q Materials cost = (C)(D) Order cost = (DS/0) Holding cost = (0/2)(n)(C) Total cost =M +0+H Average flow time=0/2D Separate vs. Joint Ordering Not surprisingly. Joint ordering lowers costs. But Why? Cost Category Materials cost Order cost Holding cost Cycle inventory (Qx312) Average flow time [Q/2D] Ordered separately $18,000,000 $146,939 $147,000 1.470 14.9 Days Ordered Jointly $18,000,000 $84,856 $84,850 849 8.6 Days Cost reduction $124.2331 Lowers ordering costs, but also lowers holding costs, beci it changes Q. Q/2 and the ordering frequency. Fixed order costs are now spread across multiple products

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock