Question: Please explain step by step thoroughly. I show example that similar and solution of it. Thank you so much. -My question that I want to

Please explain step by step thoroughly. I show example that similar and solution of it. Thank you so much.

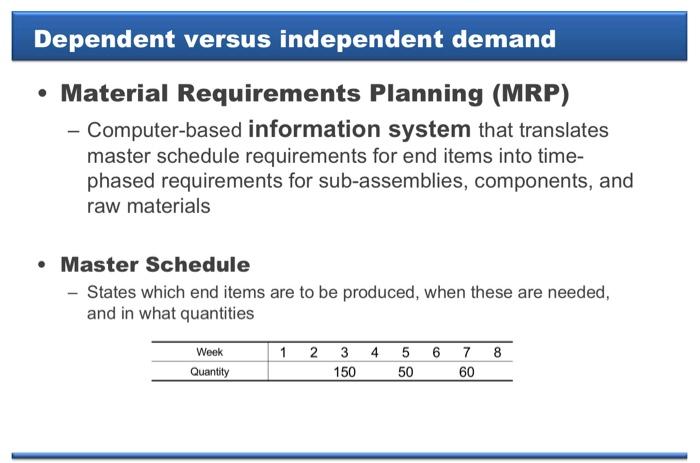

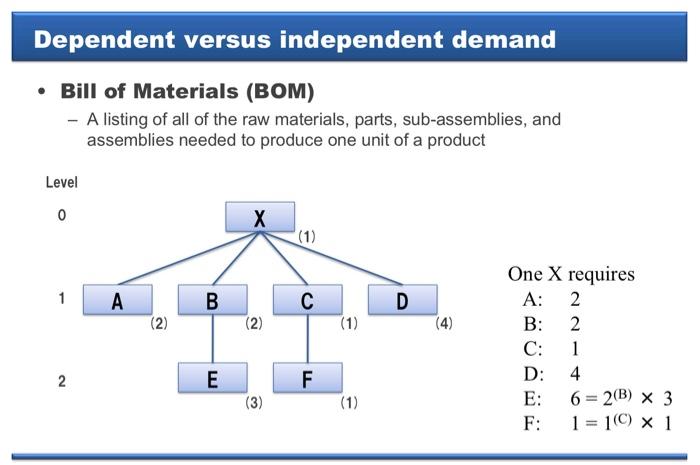

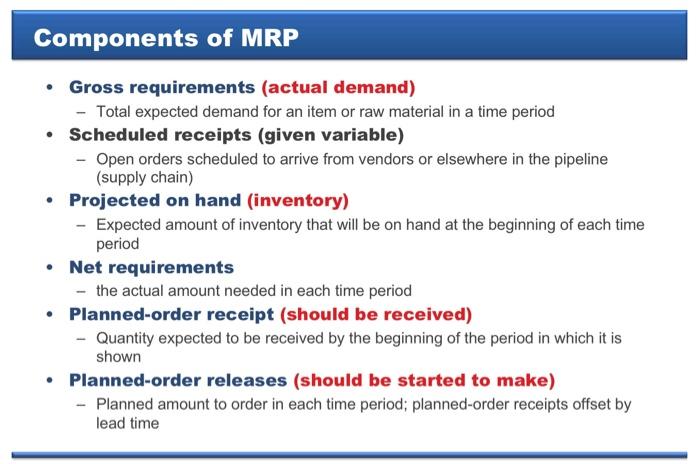

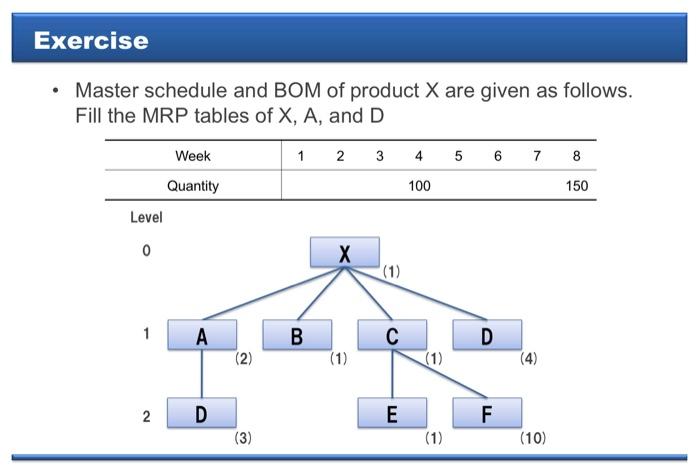

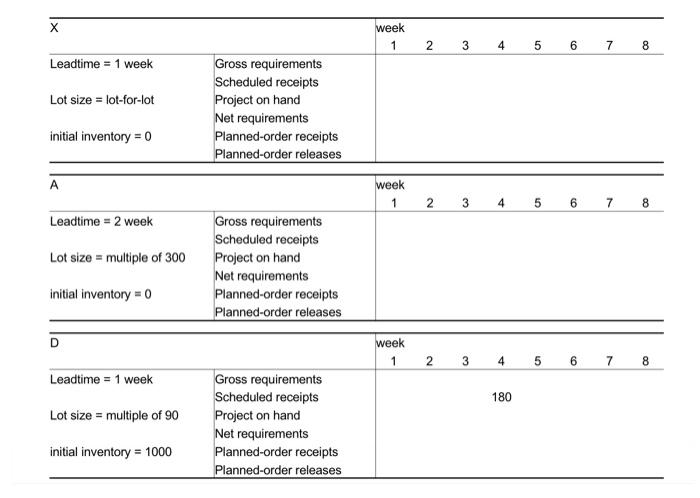

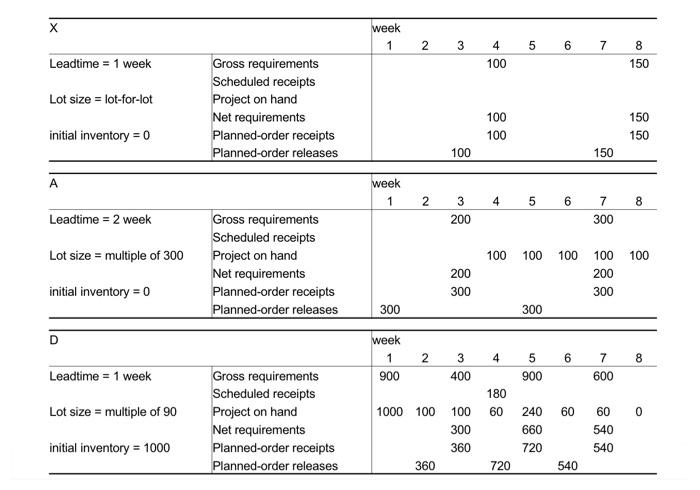

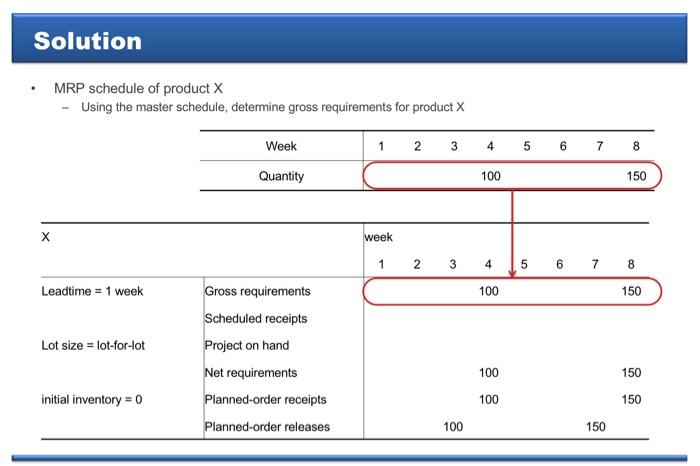

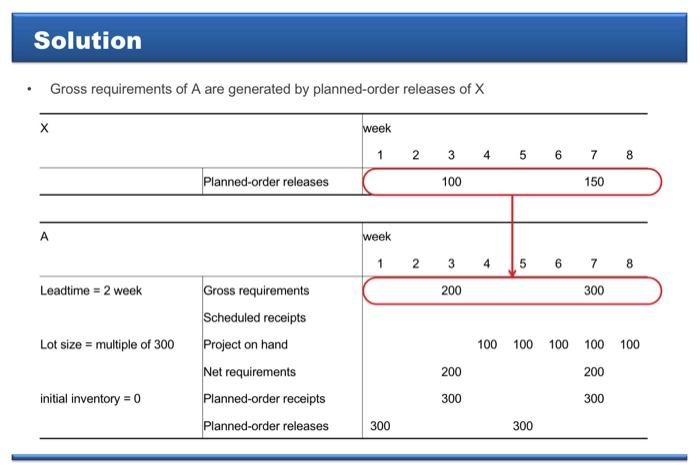

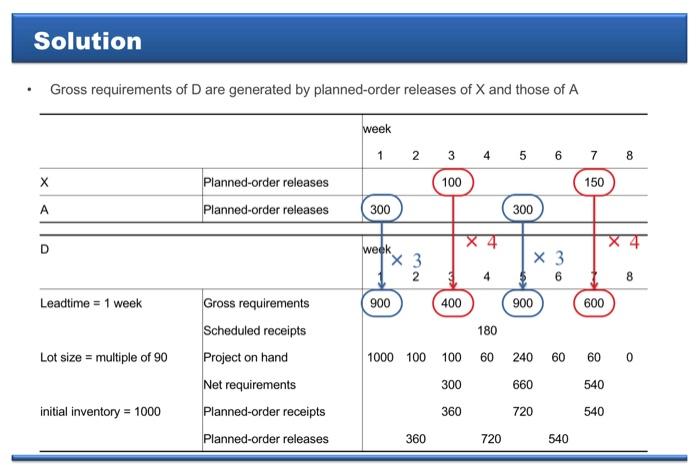

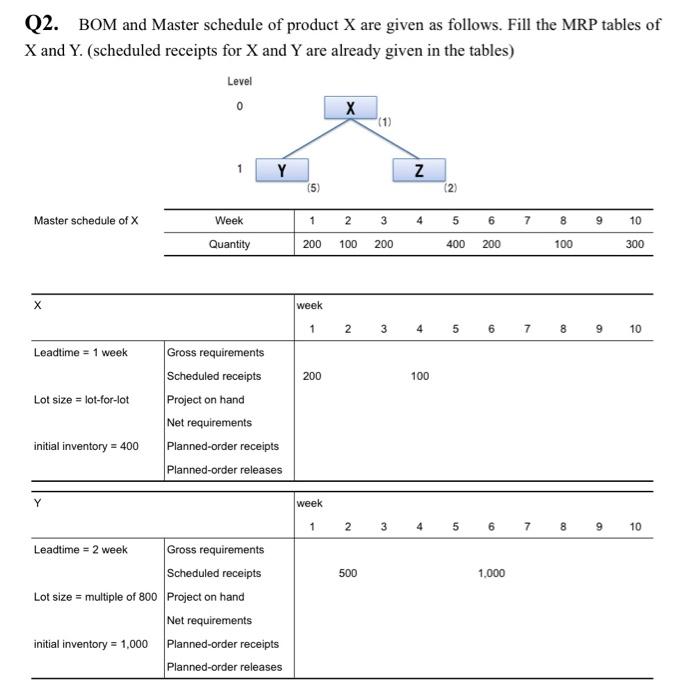

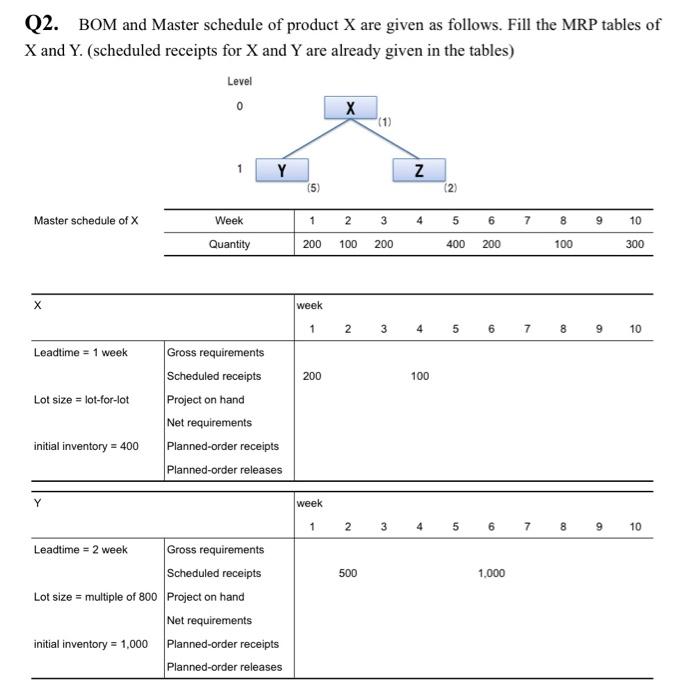

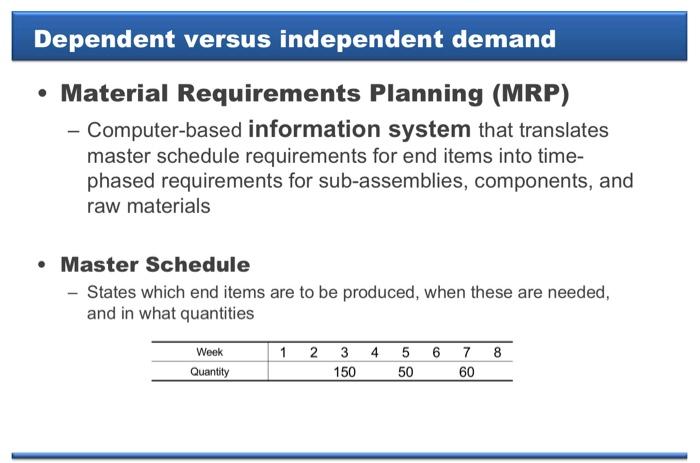

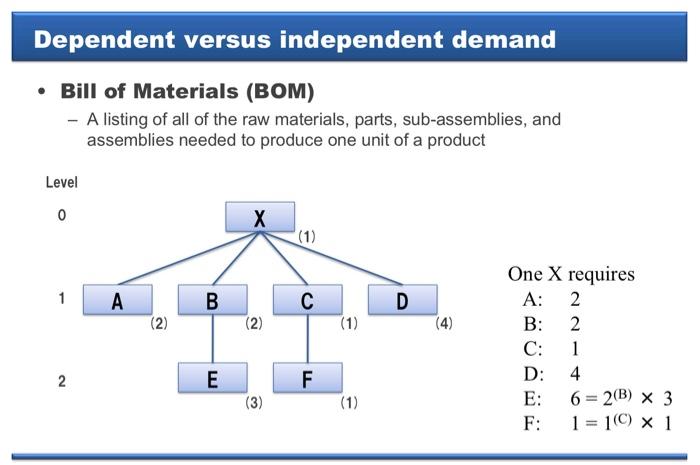

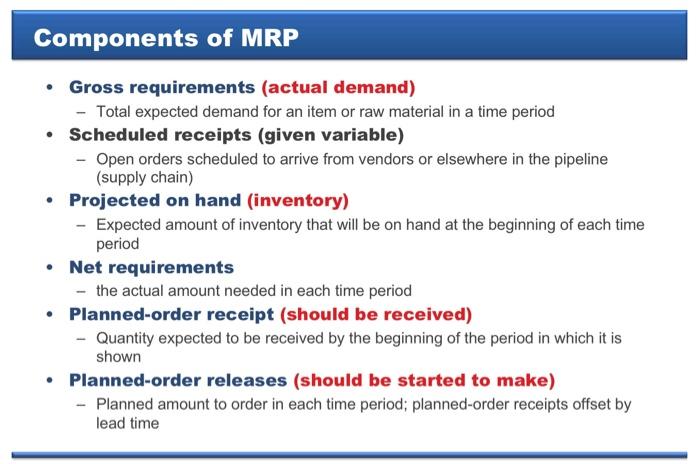

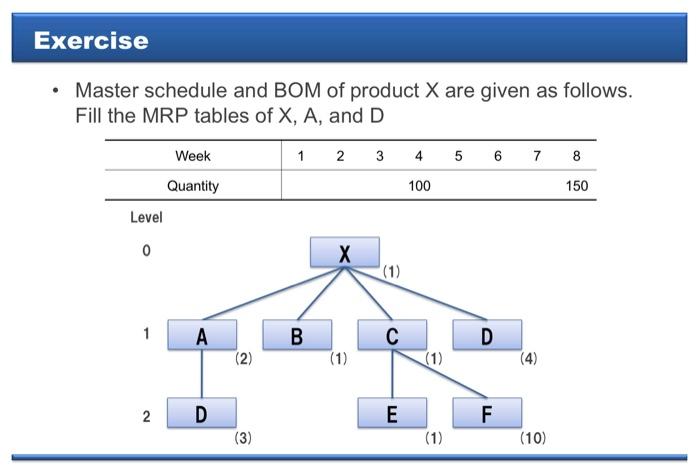

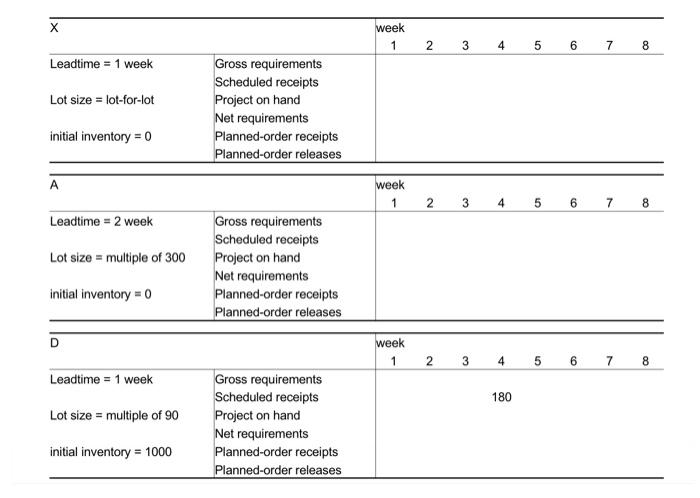

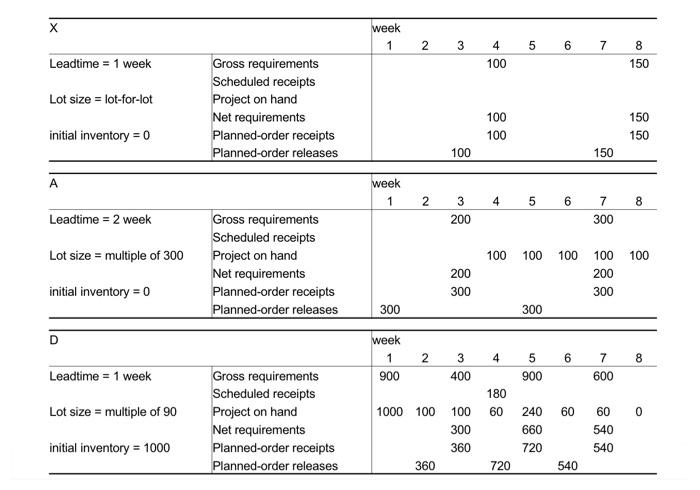

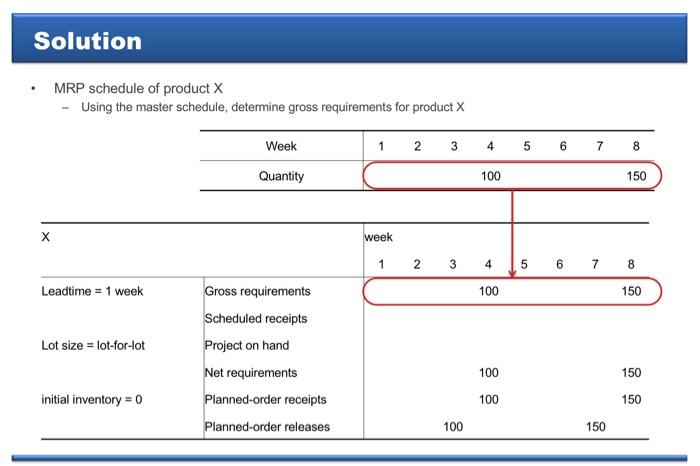

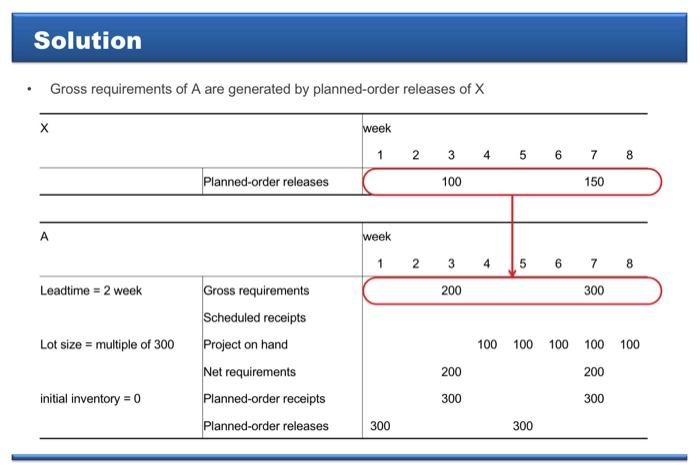

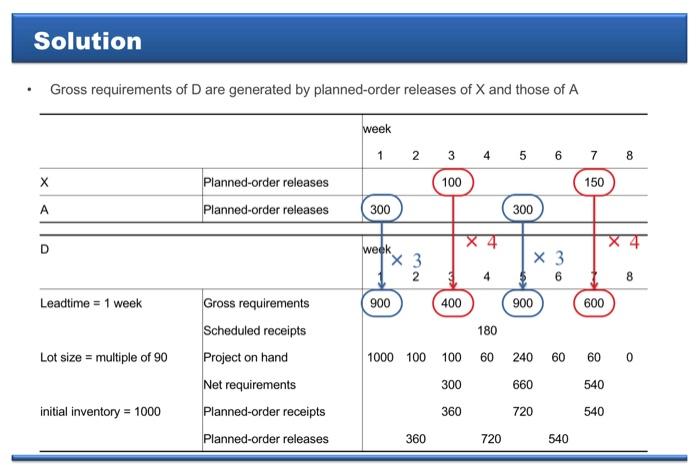

Q2. BOM and Master schedule of product X are given as follows. Fill the MRP tables of X and Y. (scheduled receipts for X and Y are already given in the tables) Level 0 1 Y Z (5) (2) Master schedule of X Week 1 2 3 4 5 7 8 9 10 Quantity 200 100 200 400 200 100 300 week 1 2 3 5 6 7 9 10 Leadtime = 1 week 200 100 Lot size = lot-for-lot Gross requirements Scheduled receipts Project on hand Net requirements Planned-order receipts Planned-order releases initial inventory = 400 Y week 1 2 3 8 9 10 500 1.000 Leadtime = 2 week Gross requirements Scheduled receipts Lot size = multiple of 800 Project on hand Net requirements initial inventory = 1,000 Planned-order receipts Planned-order releases Dependent versus independent demand Material Requirements Planning (MRP) Computer-based information system that translates master schedule requirements for end items into time- phased requirements for sub-assemblies, components, and raw materials Master Schedule - States which end items are to be produced, when these are needed, and in what quantities Week Quantity 1 2 3 4 5 6 7 8 150 50 60 Dependent versus independent demand Bill of Materials (BOM) - A listing of all of the raw materials, parts, sub-assemblies, and assemblies needed to produce one unit of a product Level 0 (1) 1 A B C D (2) (2) (1) (4) One X requires A: 2 B: 2 C: 1 D: 4 6 = 2(B) X 3 F: 1 = 1(C) x 1 2 E F (3) (1) E: Components of MRP Gross requirements (actual demand) - Total expected demand for an item or raw material in a time period Scheduled receipts (given variable) - Open orders scheduled to arrive from vendors or elsewhere in the pipeline (supply chain) Projected on hand (inventory) - Expected amount of inventory that will be on hand at the beginning of each time period Net requirements - the actual amount needed in each time period Planned-order receipt (should be received) - Quantity expected to be received by the beginning of the period in which it is shown Planned-order releases (should be started to make) - Planned amount to order in each time period; planned-order receipts offset by lead time Exercise Master schedule and BOM of product X are given as follows. Fill the MRP tables of X, A, and D 1 2 3 4 5 6 7 8 Week Quantity 100 150 Level 0 (1) 1 B B C D (2) (1) (4) 2 D E F (3) (1) (10) week 1 2 3 4 5 6 7 8 Leadtime = 1 week Lot size = lot-for-lot Gross requirements Scheduled receipts Project on hand Net requirements Planned-order receipts Planned-order releases initial inventory = 0 week 1 2 3 4 5 6 7 8 Leadtime = 2 week Lot size = multiple of 300 Gross requirements Scheduled receipts Project on hand Net requirements Planned-order receipts Planned-order releases initial inventory = 0 D week 1 2 3 4 5 6 7 8 Leadtime = 1 week 180 Lot size = multiple of 90 Gross requirements Scheduled receipts Project on hand Net requirements Planned-order receipts Planned-order releases initial inventory = 1000 week 1 N 3 co 7 8 4 100 Leadtime = 1 week 150 Lot size = lot-for-lot Gross requirements Scheduled receipts Project on hand Net requirements Planned-order receipts Planned-order releases 100 100 150 150 initial inventory = 0 100 150 A week 1 2 4 5 6 8 3 200 7 300 Leadtime = 2 week Lot size = multiple of 300 100 100 100 100 Gross requirements Scheduled receipts Project on hand Net requirements Planned-order receipts Planned-order releases 200 300 100 200 300 initial inventory = 0 300 300 D week 1 900 2 2 3 4 OD 8 3 400 5 900 7 600 Leadtime = 1 week 180 60 Lot size = multiple of 90 1000 100 60 60 0 Gross requirements Scheduled receipts Project on hand Net requirements Planned-order receipts Planned-order releases 100 300 360 240 660 720 540 540 initial inventory = 1000 360 720 540 Solution MRP schedule of product X - Using the master schedule, determine gross requirements for product X Week 1 2 3 4 5 6 7 8 Quantity 100 150 week 1 2 3 4 5 6 7 8 150 Leadtime = 1 week 100 Lot size = lot-for-lot Gross requirements Scheduled receipts Project on hand Net requirements Planned-order receipts Planned-order releases 100 150 initial inventory = 0 100 150 100 150 Solution Gross requirements of A are generated by planned-order releases of X X week 1 2 3 4 5 6 7 8 Planned-order releases 100 150 week 1 2 5 6 7 8 300 Leadtime = 2 week 200 Lot size = multiple of 300 100 100 100 100 100 Gross requirements Scheduled receipts Project on hand Net requirements Planned-order receipts Planned-order releases 200 200 initial inventory = 0 300 300 300 300 Solution Gross requirements of D are generated by planned-order releases of X and those of A week 1 2 3 4 5 6 7 8 X 100 150 Planned-order releases Planned-order releases A 300 300 X4 X 4 D week X 3 2 } X 3 5 6 4 6 8 Leadtime = 1 week 900 400 900 600 Gross requirements Scheduled receipts Project on hand Net requirements Planned-order receipts 180 60 Lot size = multiple of 90 1000 100 100 240 60 600 300 660 540 initial inventory = 1000 360 720 540 Planned-order releases 360 720 540 -My question that I want to solve.

-Example that similar and solution of it.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock