Question: please explain very carefully step by step and let me know what was used to find the answers. all I have is a calc. Dr.

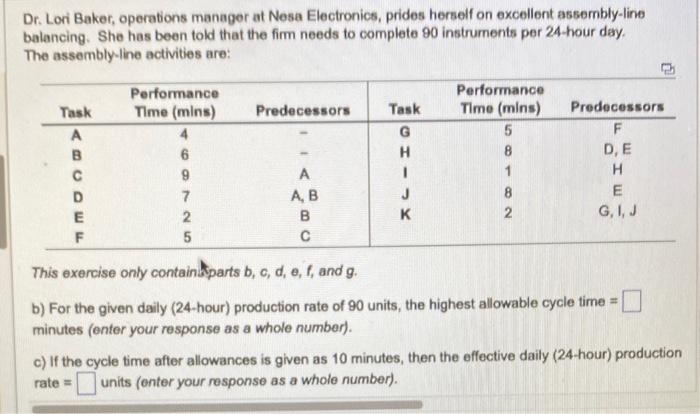

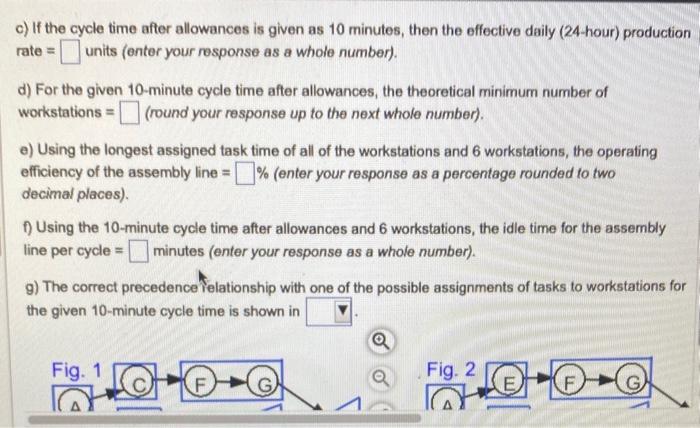

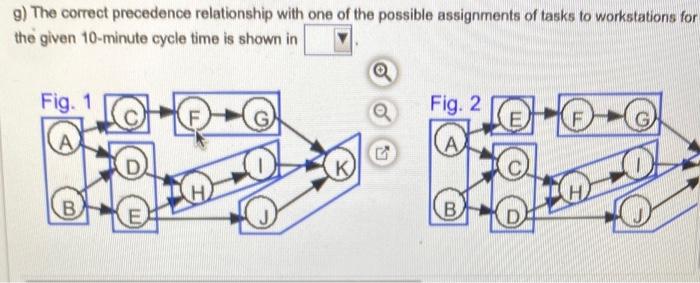

Dr. Lori Baker, operations manager at Nesa Electronics, prides herself on excellent assembly-line balancing. She has been told that the firm needs to complete 90 instruments per 24 -hour day. The assembly-line activities are: This exercise only containkparts b, c,d,e,f, and g. b) For the given daily (24-hour) production rate of 90 units, the highest allowable cycle time = minutes (enter your response as a whole number). c) If the cycle time after allowances is given as 10 minutes, then the effective daily (24-hour) production rate = units (enter your response as a whole number). c) If the cycle time after allowances is given as 10 minutes, then the effective daily (24-hour) production rate = units (enter your response as a whole number). d) For the given 10-minute cycle time after allowances, the theoretical minimum number of workstations = (round your response up to the next whole number). e) Using the longest assigned task time of all of the workstations and 6 workstations, the operating efficiency of the assembly line =% (enter your response as a percentage rounded to two decimal places). f) Using the 10-minute cycle time after allowances and 6 workstations, the idle time for the assembly line per cycle = minutes (enter your response as a whole number). g) The correct precedence ielationship with one of the possible assignments of tasks to workstations for the given 10-minute cycle time is shown in g) The correct precedence relationship with one of the possible assignments of tasks to workstations for the given 10-minute cycle time is shown in

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts