Question: Please give me step by step solution for this question A medical device company is setting up an assembly line to produce wearable health monitors.

Please give me step by step solution for this question

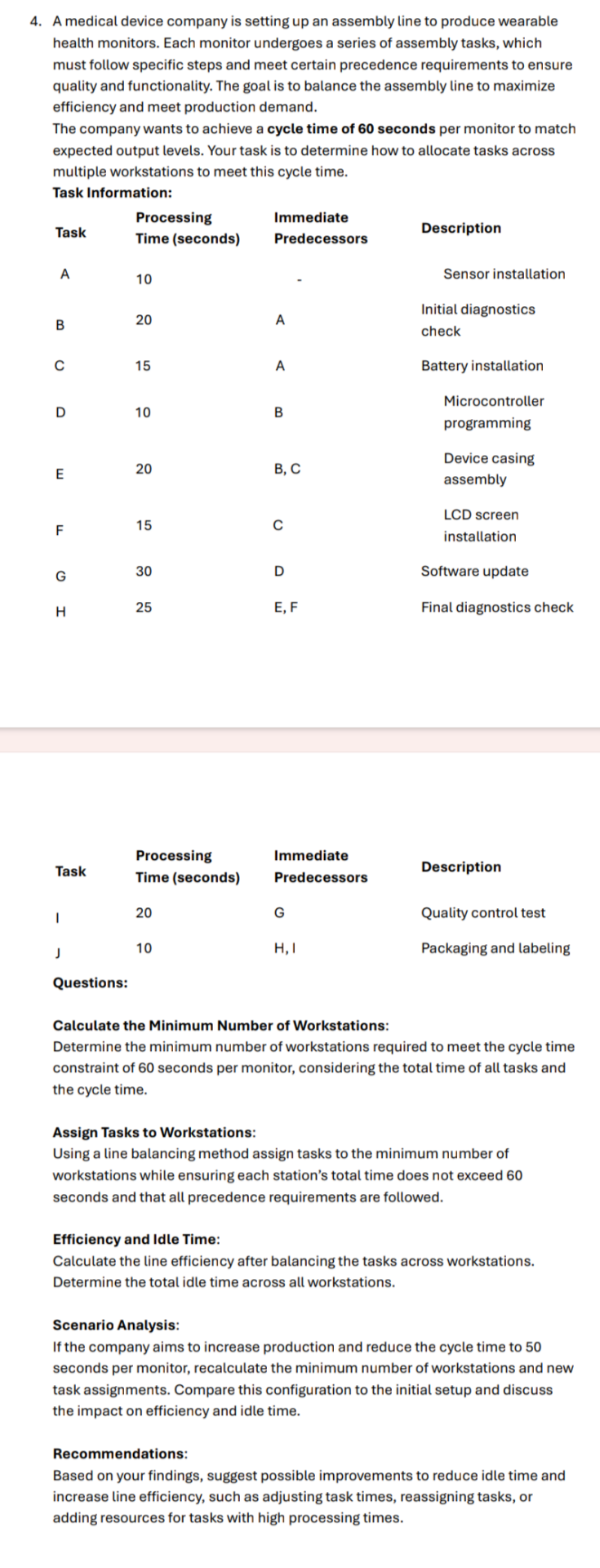

A medical device company is setting up an assembly line to produce wearable health monitors. Each monitor undergoes a series of assembly tasks, which must follow specific steps and meet certain precedence requirements to ensure quality and functionality. The goal is to balance the assembly line to maximize efficiency and meet production demand.

The company wants to achieve a cycle time of seconds per monitor to match expected output levels. Your task is to determine how to allocate tasks across multiple workstations to meet this cycle time.

Task Information:

tableTasktableProcessingTime secondstableImmediatePredecessorsDescriptionASensor installationBAInitial diagnostics checkCABattery installationDBMicrocontroller programmingEB CDevice casing assemblyFCLCD screen installationGDSoftware updateHE FFinal diagnostics check

tableTasktableProcessingTime secondstableImmediatePredecessorsDescriptionIGQuality control testJI,Packaging and labeling

Questions:

Calculate the Minimum Number of Workstations:

Determine the minimum number of workstations required to meet the cycle time constraint of seconds per monitor, considering the total time of all tasks and the cycle time.

Assign Tasks to Workstations:

Using a line balancing method assign tasks to the minimum number of workstations while ensuring each station's total time does not exceed seconds and that all precedence requirements are followed.

Efficiency and Idle Time:

Calculate the line efficiency after balancing the tasks across workstations. Determine the total idle time across all workstations.

Scenario Analysis:

If the company aims to increase production and reduce the cycle time to seconds per monitor, recalculate the minimum number of workstations and new task assignments. Compare this configuration to the initial setup and discuss the impact on efficiency and idle time.

Recommendations:

Based on your findings, suggest possible improvements to reduce idle time and increase line efficiency, such as adjusting task times, reassigning tasks, or adding resources for tasks with high processing times.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock