Question: Please help answer the question. Please answer the first question use the 4 example of answers and templates to answer given. Tq so much for

Please help answer the question.

Please answer the first question use the 4 example of answers and templates to answer given.

Tq so much for your help.

The question is on the first photo on top.

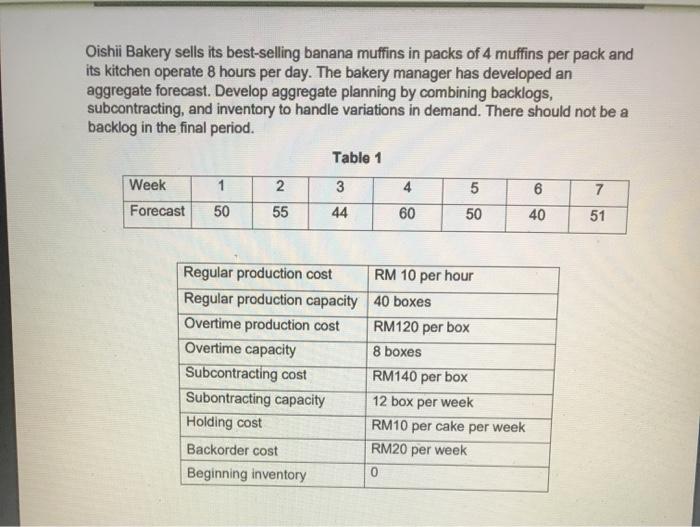

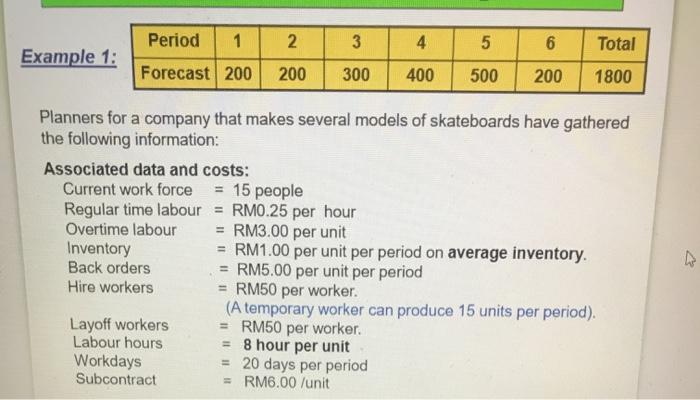

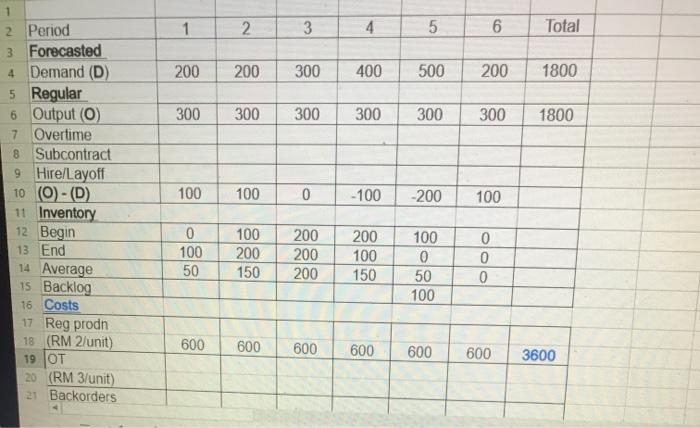

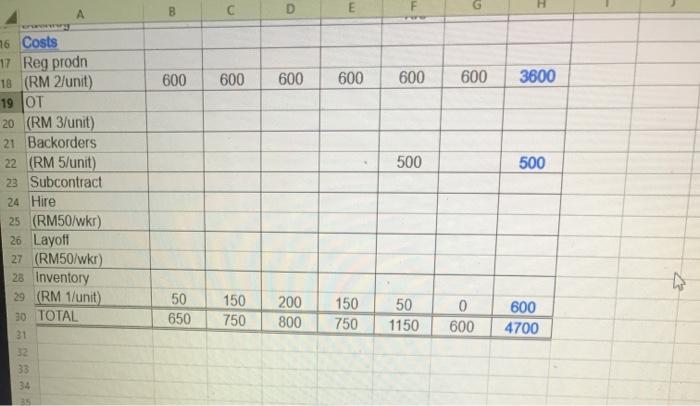

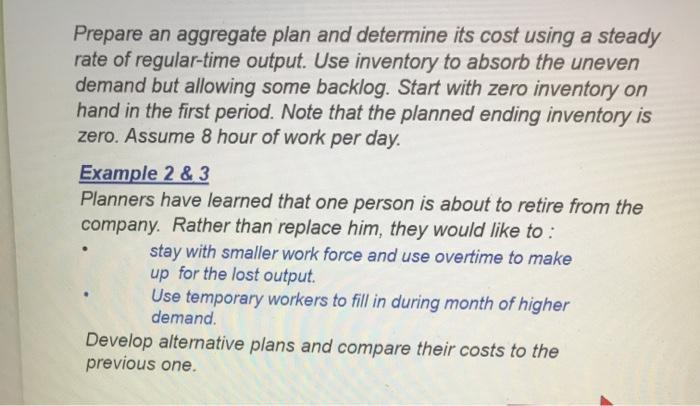

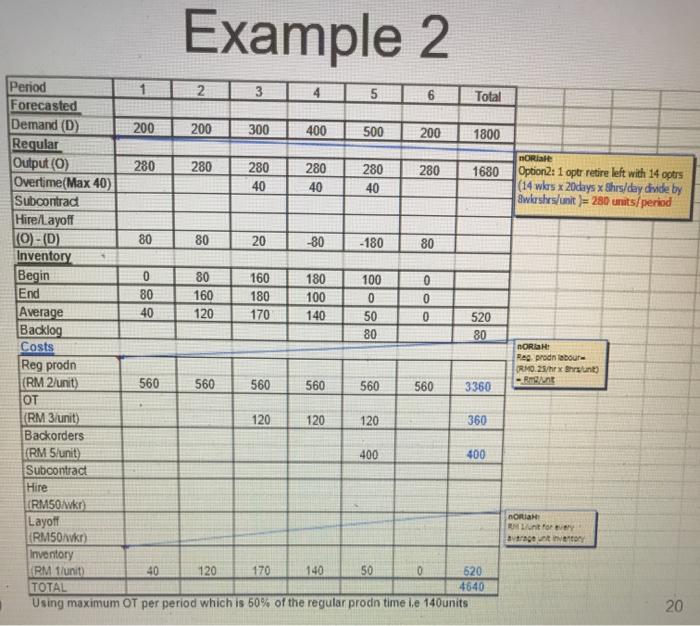

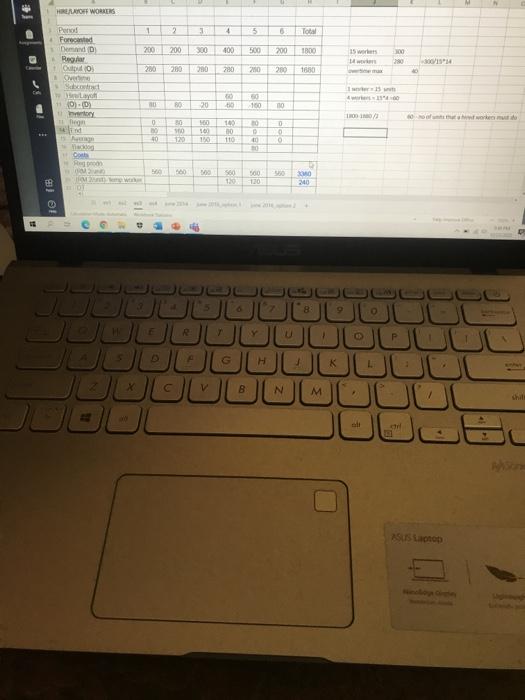

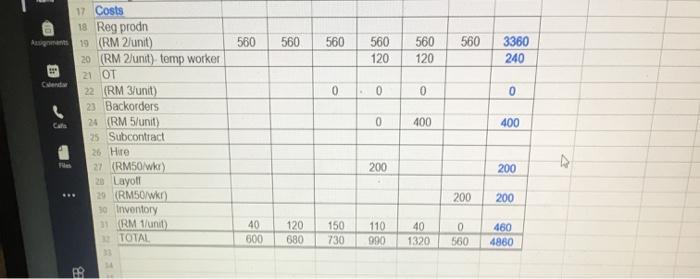

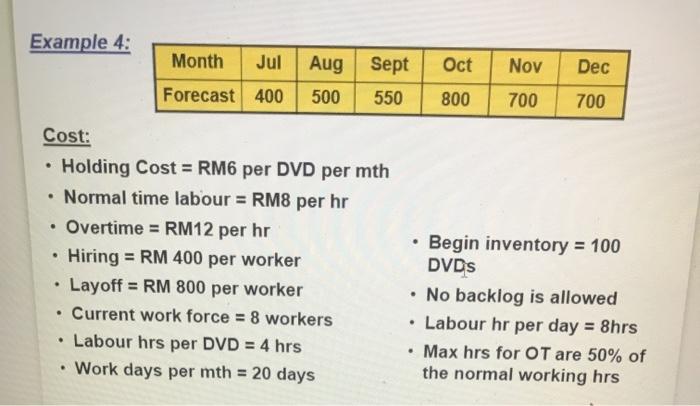

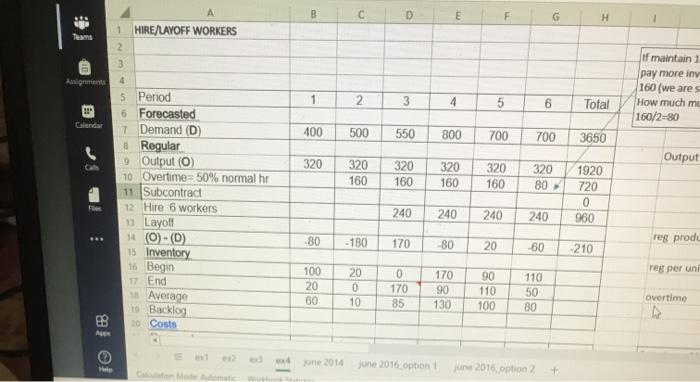

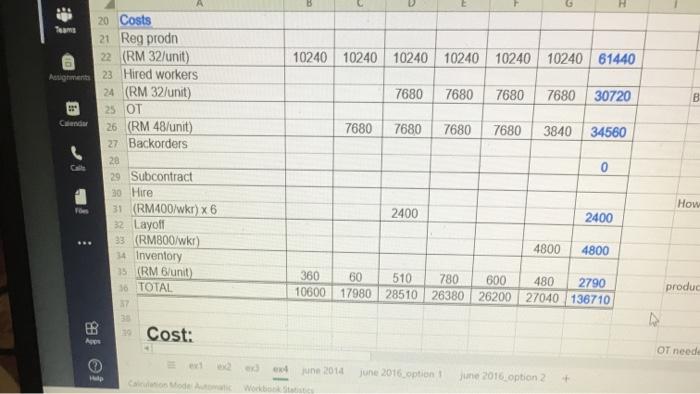

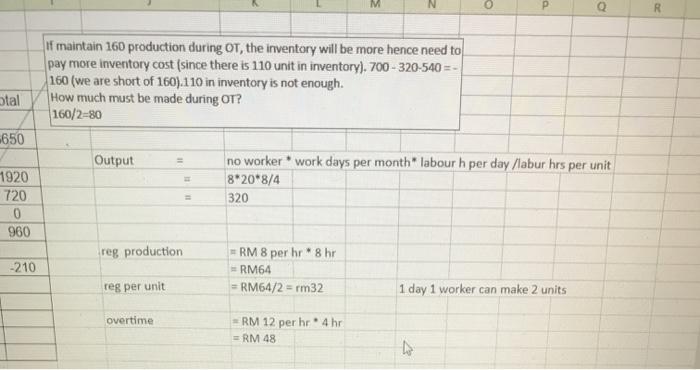

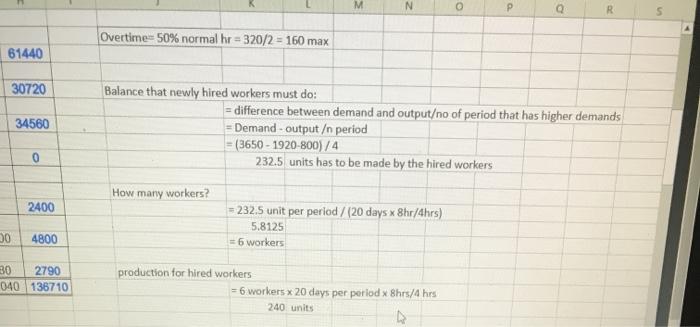

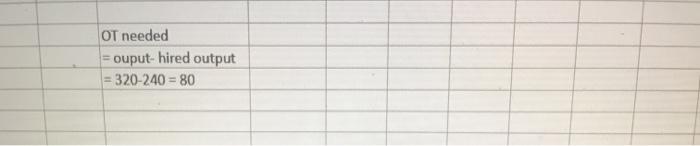

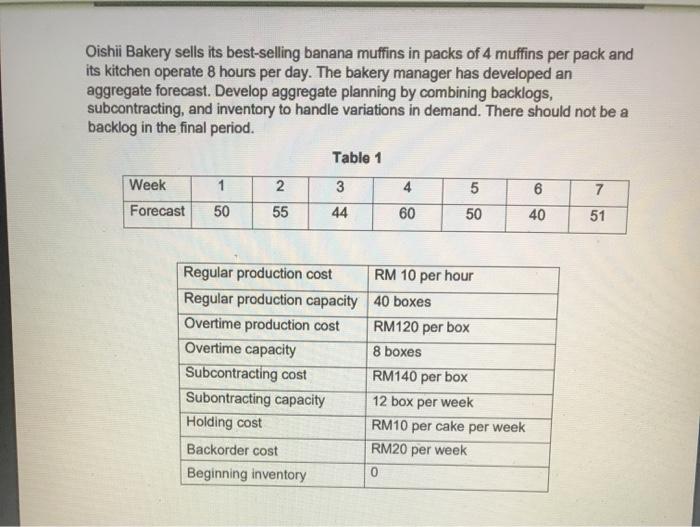

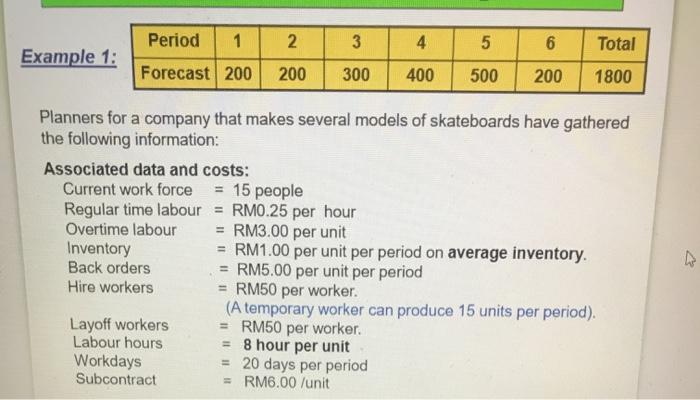

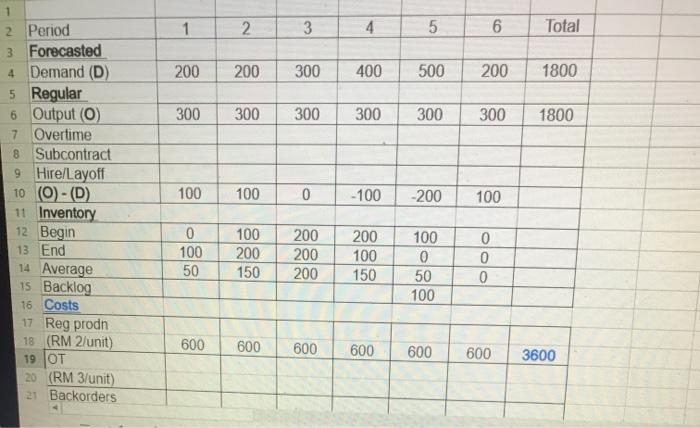

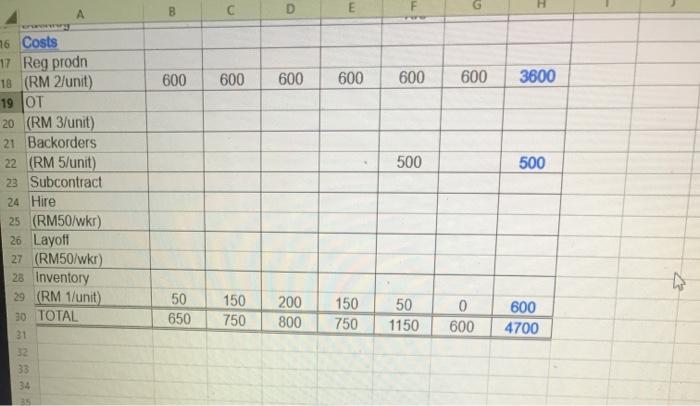

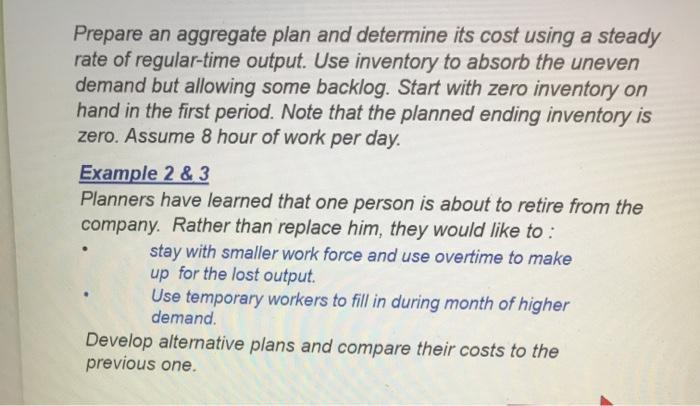

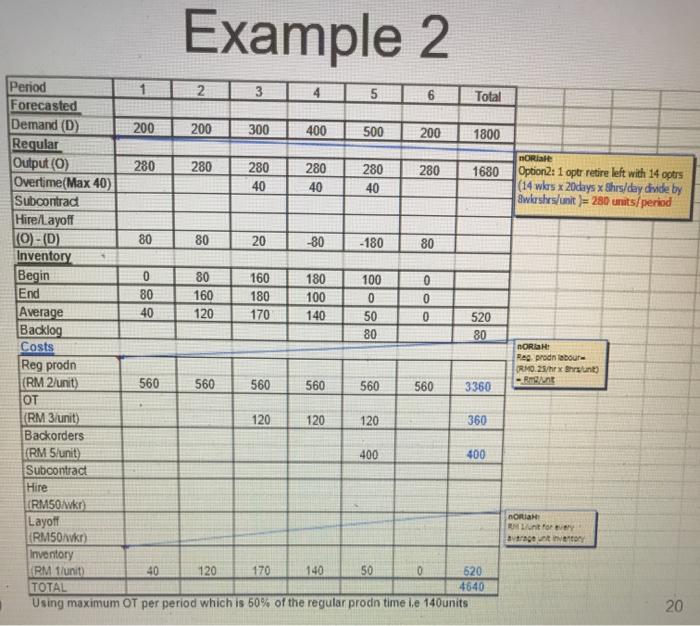

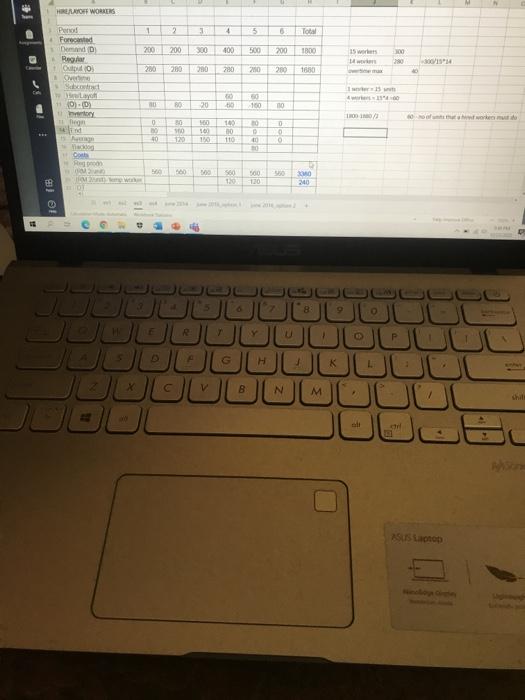

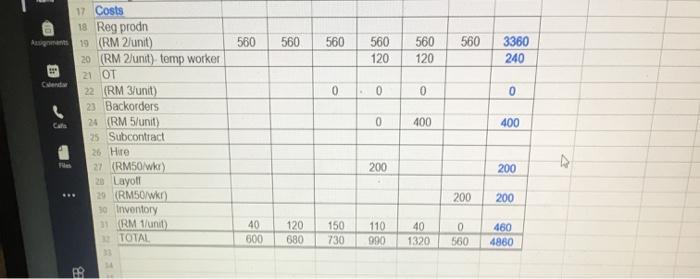

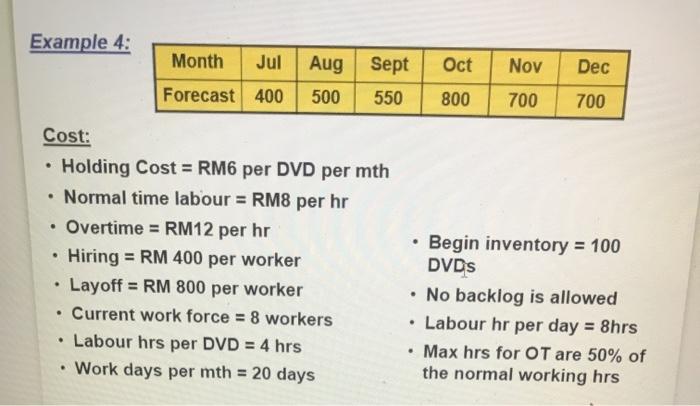

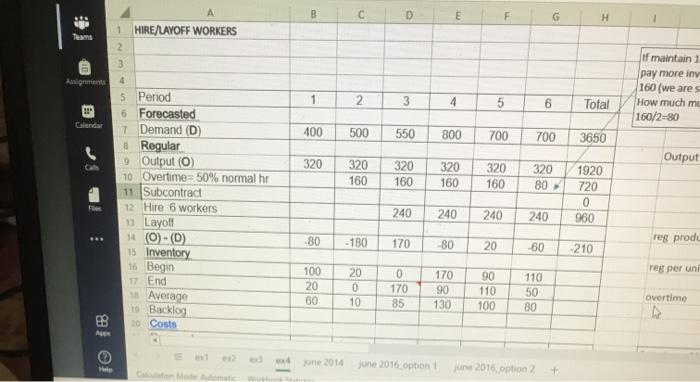

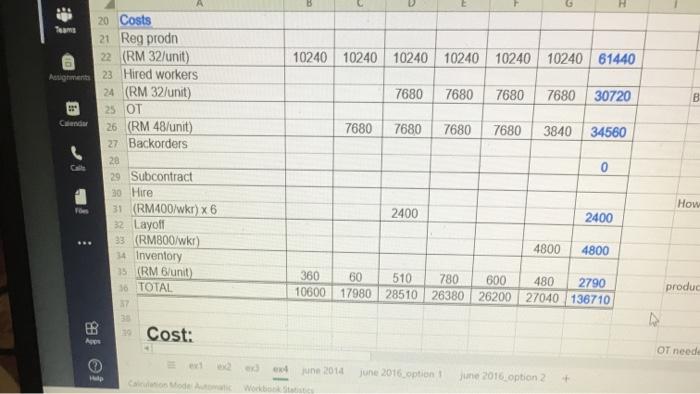

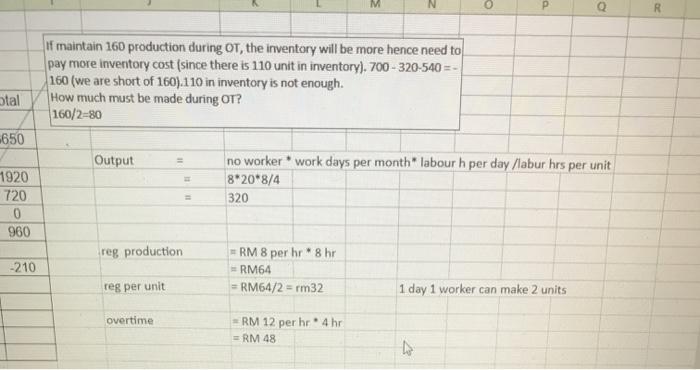

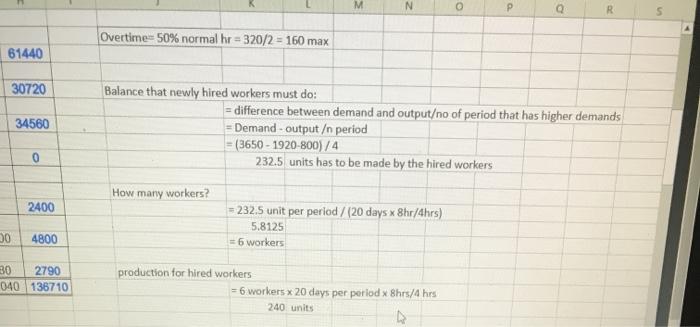

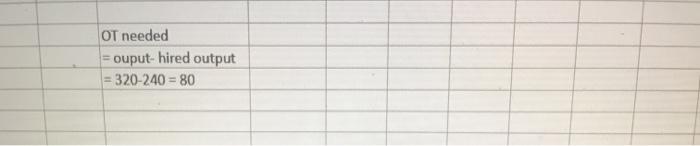

Oishii Bakery sells its best-selling banana muffins in packs of 4 muffins per pack and its kitchen operate 8 hours per day. The bakery manager has developed an aggregate forecast. Develop aggregate planning by combining backlogs, subcontracting, and inventory to handle variations in demand. There should not be a backlog in the final period. Table 1 Week 2 3 4 5 5 6 7 Forecast 50 55 44 60 50 40 51 Regular production cost RM 10 per hour Regular production capacity 40 boxes Overtime production cost RM120 per box Overtime capacity 8 boxes Subcontracting cost RM140 per box Subontracting capacity 12 box per week Holding cost RM10 per cake per week Backorder cost RM20 per week Beginning inventory Period 1 2 3 4 5 6 Total Example 1: Forecast 200 200 300 400 500 200 1800 Planners for a company that makes several models of skateboards have gathered the following information: Associated data and costs: Current work force = 15 people Regular time labour = RM0.25 per hour Overtime labour = RM3.00 per unit Inventory RM1.00 per unit per period on average inventory. Back orders = RM5.00 per unit per period Hire workers = RM50 per worker. (A temporary worker can produce 15 units per period). Layoff workers = RM50 per worker Labour hours = 8 hour per unit Workdays = 20 days per period Subcontract = RM6.00/unit 1 2. 3 4 5 6 Total 200 200 300 400 500 200 1800 300 300 300 300 300 300 1800 100 100 0 -100 -200 1 2 Period 3 Forecasted 4 Demand (D) 5 Regular 6 Output (0) 7 Overtime 8 Subcontract 9 Hire/Layoff 10 (O) -(D) 11 Inventory 12 Begin 13 End 14 Average 15 Backlog 16 Costs 17 Reg prodn 18 (RM 2/unit) 19 OT 20 (RM 3/unit) 21 Backorders 100 0 100 50 100 200 150 200 200 200 200 100 150 100 0 50 100 0 0 0 600 600 600 600 600 600 3600 E A 600 600 600 600 600 600 3600 500 500 16 Costs 17 Reg prodn 18 (RM 2/unit) 19 OT 20 (RM 3/unit) 21 Backorders 22 (RM 5/unit) 23 Subcontract 24 Hire 25 (RM50/wkr) 26 Layoff 27 (RM50/wkr) 28 Inventory 29 (RM 1/unit) 30 TOTAL 31 50 650 150 750 200 800 150 750 50 1150 0 600 600 4700 32 33 34 Prepare an aggregate plan and determine its cost using a steady rate of regular-time output. Use inventory to absorb the uneven demand but allowing some backlog. Start with zero inventory on hand in the first period. Note that the planned ending inventory is zero. Assume 8 hour of work per day. Example 2 & 3 Planners have learned that one person is about to retire from the company. Rather than replace him, they would like to: stay with smaller work force and use overtime to make up for the lost output. Use temporary workers to fill in during month of higher demand. Develop alternative plans and compare their costs to the previous one. Example 2 ololo Period 2 3 5 6 Total Forecasted Demand (D) 200 200 300 400 500 200 1800 Regular noriale Output (0) 280 280 280 280 280 280 1680 Option2: 1 optr retire left with 14 optrs Overtime(Max 40) 40 40 40 (14 wkrs x 20days x Shrs/day divide by Subcontract awkershrs/unit )= 280 units/period Hire/Layoff (0) -(D) 80 80 20 -80 -180 80 Inventory Begin 0 80 160 180 100 End 80 160 180 100 0 Average 40 120 170 140 50 520 Backlog 80 80 Costs NORHI Red prodnabout Reg prodn ORMO. 25/hrx Shrsunt) (RM 2 unit) unt 560 560 560 560 560 560 3360 OT (RM 3/unit) 120 120 120 360 Backorders LRM 5 unit) 400 400 Subcontract Hire (RM50/kr) nora Layoff Auto RM50/kr) te ty Inventory RM 1unit) 40 120 170 140 50 0 620 TOTAL 4640 Using maximum OT per period which is 50% of the regular prodn time ie 140units 20 HREOFF WORKERS Total * 1 TADO = === ( 00 200 Pero Forced Demand Regar to 0 Over | 16 2 0 - (0) == | OL R y F L K H M / \ N ASUS Lanco ALS 560 560 560 560 560 120 560 120 3360 240 0 0 0 0 17 Costs 18 Reg prodn 19 (RM 2 unit) 20 (RM 2 unit) temp worker 21 OT 22 (RM 3/unit) 23 Backorders 24 (RM 5/unit) 25 Subcontract 26 Hire 27 (RM50/Wkt) 20 Layoli 29 (RM50/WKO) 30 Inventory 31 (RM 1/unit) TOTAL 0 400 400 200 200 200 200 40 600 120 680 150 730 110 990 40 1320 0 560 460 4860 98 Example 4: Month Jul Oct Nov Dec Aug Sept 500 550 Forecast 400 800 700 700 . Cost: Holding Cost = RM6 per DVD per mth Normal time labour = RM8 per hr Overtime = RM12 per hr Hiring = RM 400 per worker Layoff = RM 800 per worker Current work force = 8 workers Labour hrs per DVD = 4 hrs Work days per mth = 20 days . . Begin inventory = 100 DVDs No backlog is allowed Labour hr per day = 8hrs Max hrs for OT are 50% of the normal working hrs . . C D E F G H OB Animas If maintain 1 pay more iny 160 (we are How much me 160/2=80 1 2 3 4 ch 5 6 Total 1 400 500 550 800 700 700 3650 320 Output 1 HIRE/LAYOFF WORKERS 2 3 4 5 Period 6 Forecasted 7 Demand (D) 8 Regular 9 Output (0) 10 Overtime = 50% normal hr 11 Subcontract 12 Hire 6 workers 1 Layoff 14 (O) -() 15 Inventory 16 Begin 17 End Average 1 Backlog 20 Costs 320 160 320 160 320 160 320 320 160 80 1920 720 0 960 F 240 240 240 240 BBS -80 -180 170 80 reg produ 20 -60 -210 reg per un 170 100 20 00 20 0 10 0 170 85 90 90 110 100 110 50 80 overtime 130 une 2014 June 2016 option June 2016 option G H Teams 10240 10240 10240 10240 10240 10240 61440 Argument 7680 7680 7680 7680 30720 B Cedar 7680 7680 7680 7680 3840 34560 20 Costs 21 Reg prodn 22 (RM 32/unit) 23 Hired workers 24 (RM 32/unit) 25 OT 26 (RM 48/unit) 27 Backorders 28 29 Subcontract 30 Hire 31 (RM400/wkr) x 6 32. Layoll 33 (RM800/kr) 34 Inventory 35 (RM 6/unit 36 TOTAL 0 How 2400 2400 *** 4800 4800 360 10600 60 510 1798028510 780 600 480 2790 26380 26200 27040 136710 produc BB 30 1 Cost: OT neede June 2014 June 2016 option June 2016 option WS o P Q R of maintain 160 production during OT, the inventory will be more hence need to pay more inventory cost (since there is 110 unit in inventory). 700 - 320-540 =- 160 (we are short of 160).110 in inventory is not enough. How much must be made during OT? 160/2=80 otal 650 Output 1920 720 0 960 no worker work days per month labour h per day /labur hrs per unit 8*20*8/4 320 reg production -210 = RM 8 per hr hr -RM64 RM64/2 = rm32 reg per unit 1 day 1 worker can make 2 units overtime RM 12 per hr 4hr = RM 48 M N P Q R S Overtime-50% normal hr = 320/2 = 160 max 61440 30720 34560 Balance that newly hired workers must do: = difference between demand and outputo of period that has higher demands = Demand-output period = (3650 - 1920-800)/4 232.5 units has to be made by the hired workers 0 How many workers? 2400 = 232.5 unit per period / (20 days x 8hr/4hrs) 5.8125 = 6 workers 30 4800 30 2790 040 136710 production for hired workers = 6 workers x 20 days per period 8hrs/4hrs 240 units OT needed Fouput- hired output 320-240 = 80 Oishii Bakery sells its best-selling banana muffins in packs of 4 muffins per pack and its kitchen operate 8 hours per day. The bakery manager has developed an aggregate forecast. Develop aggregate planning by combining backlogs, subcontracting, and inventory to handle variations in demand. There should not be a backlog in the final period. Table 1 Week 2 3 4 5 5 6 7 Forecast 50 55 44 60 50 40 51 Regular production cost RM 10 per hour Regular production capacity 40 boxes Overtime production cost RM120 per box Overtime capacity 8 boxes Subcontracting cost RM140 per box Subontracting capacity 12 box per week Holding cost RM10 per cake per week Backorder cost RM20 per week Beginning inventory Period 1 2 3 4 5 6 Total Example 1: Forecast 200 200 300 400 500 200 1800 Planners for a company that makes several models of skateboards have gathered the following information: Associated data and costs: Current work force = 15 people Regular time labour = RM0.25 per hour Overtime labour = RM3.00 per unit Inventory RM1.00 per unit per period on average inventory. Back orders = RM5.00 per unit per period Hire workers = RM50 per worker. (A temporary worker can produce 15 units per period). Layoff workers = RM50 per worker Labour hours = 8 hour per unit Workdays = 20 days per period Subcontract = RM6.00/unit 1 2. 3 4 5 6 Total 200 200 300 400 500 200 1800 300 300 300 300 300 300 1800 100 100 0 -100 -200 1 2 Period 3 Forecasted 4 Demand (D) 5 Regular 6 Output (0) 7 Overtime 8 Subcontract 9 Hire/Layoff 10 (O) -(D) 11 Inventory 12 Begin 13 End 14 Average 15 Backlog 16 Costs 17 Reg prodn 18 (RM 2/unit) 19 OT 20 (RM 3/unit) 21 Backorders 100 0 100 50 100 200 150 200 200 200 200 100 150 100 0 50 100 0 0 0 600 600 600 600 600 600 3600 E A 600 600 600 600 600 600 3600 500 500 16 Costs 17 Reg prodn 18 (RM 2/unit) 19 OT 20 (RM 3/unit) 21 Backorders 22 (RM 5/unit) 23 Subcontract 24 Hire 25 (RM50/wkr) 26 Layoff 27 (RM50/wkr) 28 Inventory 29 (RM 1/unit) 30 TOTAL 31 50 650 150 750 200 800 150 750 50 1150 0 600 600 4700 32 33 34 Prepare an aggregate plan and determine its cost using a steady rate of regular-time output. Use inventory to absorb the uneven demand but allowing some backlog. Start with zero inventory on hand in the first period. Note that the planned ending inventory is zero. Assume 8 hour of work per day. Example 2 & 3 Planners have learned that one person is about to retire from the company. Rather than replace him, they would like to: stay with smaller work force and use overtime to make up for the lost output. Use temporary workers to fill in during month of higher demand. Develop alternative plans and compare their costs to the previous one. Example 2 ololo Period 2 3 5 6 Total Forecasted Demand (D) 200 200 300 400 500 200 1800 Regular noriale Output (0) 280 280 280 280 280 280 1680 Option2: 1 optr retire left with 14 optrs Overtime(Max 40) 40 40 40 (14 wkrs x 20days x Shrs/day divide by Subcontract awkershrs/unit )= 280 units/period Hire/Layoff (0) -(D) 80 80 20 -80 -180 80 Inventory Begin 0 80 160 180 100 End 80 160 180 100 0 Average 40 120 170 140 50 520 Backlog 80 80 Costs NORHI Red prodnabout Reg prodn ORMO. 25/hrx Shrsunt) (RM 2 unit) unt 560 560 560 560 560 560 3360 OT (RM 3/unit) 120 120 120 360 Backorders LRM 5 unit) 400 400 Subcontract Hire (RM50/kr) nora Layoff Auto RM50/kr) te ty Inventory RM 1unit) 40 120 170 140 50 0 620 TOTAL 4640 Using maximum OT per period which is 50% of the regular prodn time ie 140units 20 HREOFF WORKERS Total * 1 TADO = === ( 00 200 Pero Forced Demand Regar to 0 Over | 16 2 0 - (0) == | OL R y F L K H M / \ N ASUS Lanco ALS 560 560 560 560 560 120 560 120 3360 240 0 0 0 0 17 Costs 18 Reg prodn 19 (RM 2 unit) 20 (RM 2 unit) temp worker 21 OT 22 (RM 3/unit) 23 Backorders 24 (RM 5/unit) 25 Subcontract 26 Hire 27 (RM50/Wkt) 20 Layoli 29 (RM50/WKO) 30 Inventory 31 (RM 1/unit) TOTAL 0 400 400 200 200 200 200 40 600 120 680 150 730 110 990 40 1320 0 560 460 4860 98 Example 4: Month Jul Oct Nov Dec Aug Sept 500 550 Forecast 400 800 700 700 . Cost: Holding Cost = RM6 per DVD per mth Normal time labour = RM8 per hr Overtime = RM12 per hr Hiring = RM 400 per worker Layoff = RM 800 per worker Current work force = 8 workers Labour hrs per DVD = 4 hrs Work days per mth = 20 days . . Begin inventory = 100 DVDs No backlog is allowed Labour hr per day = 8hrs Max hrs for OT are 50% of the normal working hrs . . C D E F G H OB Animas If maintain 1 pay more iny 160 (we are How much me 160/2=80 1 2 3 4 ch 5 6 Total 1 400 500 550 800 700 700 3650 320 Output 1 HIRE/LAYOFF WORKERS 2 3 4 5 Period 6 Forecasted 7 Demand (D) 8 Regular 9 Output (0) 10 Overtime = 50% normal hr 11 Subcontract 12 Hire 6 workers 1 Layoff 14 (O) -() 15 Inventory 16 Begin 17 End Average 1 Backlog 20 Costs 320 160 320 160 320 160 320 320 160 80 1920 720 0 960 F 240 240 240 240 BBS -80 -180 170 80 reg produ 20 -60 -210 reg per un 170 100 20 00 20 0 10 0 170 85 90 90 110 100 110 50 80 overtime 130 une 2014 June 2016 option June 2016 option G H Teams 10240 10240 10240 10240 10240 10240 61440 Argument 7680 7680 7680 7680 30720 B Cedar 7680 7680 7680 7680 3840 34560 20 Costs 21 Reg prodn 22 (RM 32/unit) 23 Hired workers 24 (RM 32/unit) 25 OT 26 (RM 48/unit) 27 Backorders 28 29 Subcontract 30 Hire 31 (RM400/wkr) x 6 32. Layoll 33 (RM800/kr) 34 Inventory 35 (RM 6/unit 36 TOTAL 0 How 2400 2400 *** 4800 4800 360 10600 60 510 1798028510 780 600 480 2790 26380 26200 27040 136710 produc BB 30 1 Cost: OT neede June 2014 June 2016 option June 2016 option WS o P Q R of maintain 160 production during OT, the inventory will be more hence need to pay more inventory cost (since there is 110 unit in inventory). 700 - 320-540 =- 160 (we are short of 160).110 in inventory is not enough. How much must be made during OT? 160/2=80 otal 650 Output 1920 720 0 960 no worker work days per month labour h per day /labur hrs per unit 8*20*8/4 320 reg production -210 = RM 8 per hr hr -RM64 RM64/2 = rm32 reg per unit 1 day 1 worker can make 2 units overtime RM 12 per hr 4hr = RM 48 M N P Q R S Overtime-50% normal hr = 320/2 = 160 max 61440 30720 34560 Balance that newly hired workers must do: = difference between demand and outputo of period that has higher demands = Demand-output period = (3650 - 1920-800)/4 232.5 units has to be made by the hired workers 0 How many workers? 2400 = 232.5 unit per period / (20 days x 8hr/4hrs) 5.8125 = 6 workers 30 4800 30 2790 040 136710 production for hired workers = 6 workers x 20 days per period 8hrs/4hrs 240 units OT needed Fouput- hired output 320-240 = 80 The other photo is only the other example question and solution for your reference on how to answer.

But youre required to use the example template given to answer the question.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock