Question: Please Help create the flowchart for this process: Cycle Count and Annual Physical Count Cycle Count is performed in the US Warehouses (Miramar and Lombard)

Please Help create the flowchart for this process:

Cycle Count and Annual Physical Count

Cycle Count is performed in the US Warehouses (Miramar and Lombard) and Aerotech (3PL warehouse). Aerotech is using Oracle and performs cycle count following the process outlined below. Cycle count is not applied to other 3PL warehouses that do not use Oracle. Annual physical count is performed at these locations where the US warehouse team provides count sheets, 3PL and other locations performs the count and report the variances, and the Director of Global Logistics records the adjustments in Oracle based on the general ledger account code provided by the Accounting team. At a minimum, all inventories in various locations are counted at least once a year.

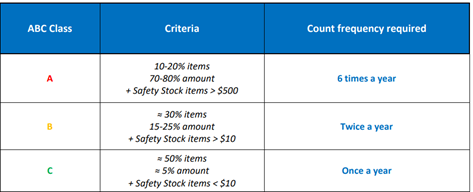

The Company uses ABC inventory classification in performing cycle counts. Quarterly, the Senior Manager Requirements Planning reviews the appropriateness of the ABC criteria.

US Cycle Count Process Effective April 2021

Prior to 2021, the US warehouse team uses a manual process in scheduling cycle counts, and cycle counts were put on hold due to various IT and Logistics issues. Effective 4/12/2021, the warehouse team in Aerotech and Lombard used Oracle cycle count module which systematically assign ABC classifications to all inventories and systematically schedule cycle counts following criteria listed below. They also follow the variance approval threshold designed by management. In Oracle, the Director of Global Logistics is able is approve variances regardless of threshold. Effective May 2021, the cycle count on Miramar location was re-instated following the Oracle systematic scheduling process.

The Logistics Supervisor manages and oversees counting process, process transactions prior to cycle counting and ensures that all handling and recording of participating inventory products are completed before the physical inventory count begins. This includes receipts, returns, consolidation between stocking locations, etc. No movement of any inventory are permitted during cycle counts. The count team consist of two people (one counter, one scanner) that count stock.

At the beginning of each week, Oracle sends an automatic email with the count schedule (blind copy inventory quantity on hand not shown) for the week to 3PL and to the Director of Global Logistics. The Cycle Count Schedule is printed from Oracle and is given to the count team where one person is assigned to count and the other to record the count using a scanner.

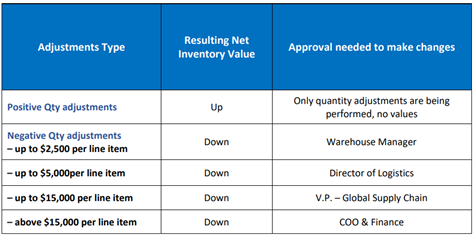

After the first count is done the Planner/Supervisor uploads the count in Oracle, generates a Cycle Count Variance Report and review the report to verify if a recount is necessary. If variances are deemed acceptable, the Director of Global Logistics approves the variances and records the adjustments. If variances are above his approval limits, the Director of Global Logistics prepares and Adjustment Request with supporting analysis/recount information and containment actions and route for approval based on the approval matrix below. The approval process is done manually via email and the system does not restrict recording of variances prior to obtaining approval. The Count sheet, Cycle count entries and adjustments report are saved on the shared drive: S:\Logistics\Private\Cycle counts 20x.

\begin{tabular}{|l|c|c|} \hline \multicolumn{1}{|c|}{ Adjustments Type } & ResultingNetInventoryValue & Approvalneededtomakechanges \\ \hline PositiveQtyadjustments & Up & Onlyquantityadjustmentsarebeingperformed,novalues \\ \hline NegativeQtyadjustments-upto$2,500perlineitem & Down & Warehouse Manager \\ \hline - up to $5,000 per line item & Down & Director of Logistics \\ \hline - up to $15,000 per line item & Down & V.P. - Global Supply Chain \\ \hline - above $15,000 per line item & Down & COO \& Finance \\ \hline \end{tabular} \begin{tabular}{|l|c|c|} \hline \multicolumn{1}{|c|}{ Adjustments Type } & ResultingNetInventoryValue & Approvalneededtomakechanges \\ \hline PositiveQtyadjustments & Up & Onlyquantityadjustmentsarebeingperformed,novalues \\ \hline NegativeQtyadjustments-upto$2,500perlineitem & Down & Warehouse Manager \\ \hline - up to $5,000 per line item & Down & Director of Logistics \\ \hline - up to $15,000 per line item & Down & V.P. - Global Supply Chain \\ \hline - above $15,000 per line item & Down & COO \& Finance \\ \hline \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts