Question: Please Help me solve and undertand the problem below. I don't understand how to build the model with all the different variables. Problem 1: Optimization

Please Help me solve and undertand the problem below. I don't understand how to build the model with all the different variables.

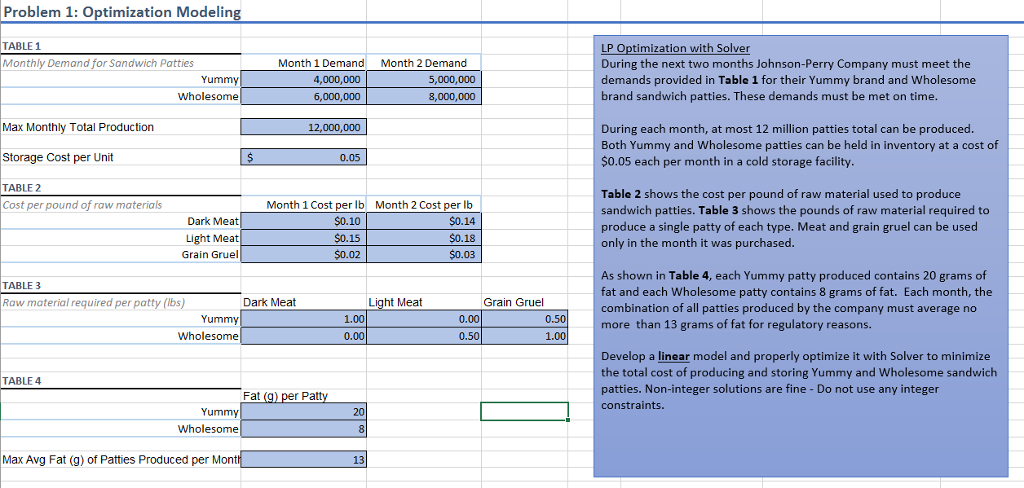

Problem 1: Optimization Modeling TABLE 1 Monthly Demand for Sandwich Patties LP Optimization with Solver Month 1 Dead 4,000,000 6,000,000 Month 2 Demand Yummy Wholesome 5,000,000 8,000,000 During the next two months Johnson-Perry Company must meet the demands provided in Table 1 for their Yummy brand and Wholesome brand sandwich patties. These demands must be met on time Max Monthly Total Production 12,000,000 During each month, at most 12 million patties total can be produced. Both Yummy and Wholesome patties can be held in inventory at a cost of $0.05 each per month in a cold storage facility Storage Cost per Unit 0.05 TABLE 2 Table 2 shows the cost per pound of raw material used to produce sandwich patties. Table 3 shows the pounds of raw material required to produce a single patty of each type. Meat and grain gruel can be used only in the month it was purchased. Cost per pound of raw materials Month 1 Cost per lb $0.10 Month 2 Cost per lb $0.14 0.18 $0.03 Dark Meat Light Meat Grain Gruel $0.02 As shown in Table 4, each Yummy patty produced contains 20 grams of fat and each Wholesome patty contains 8 grams of fat. Each month, the combination of all patties produced by the company must average no more than 13 grams of fat for regulatory reasons. IABLE3h Raw material required per patty (ibs) Dark Meat Light Meat Grain Gruel Yummy Wholesome 1.00 0.00 0.50 0.00 0.50 1.00 Develop a linear model and properly optimize it with Solver to minimize the total cost of producing and storing Yummy and Wholesome sandwich patties. Non-integer solutions are fine - Do not use any integer constraints. TABLE 4 Fat (g) per Patty Yummy Wholesome 20 Max Avg Fat (g) of Patties Produced per Mont 13 Problem 1: Optimization Modeling TABLE 1 Monthly Demand for Sandwich Patties LP Optimization with Solver Month 1 Dead 4,000,000 6,000,000 Month 2 Demand Yummy Wholesome 5,000,000 8,000,000 During the next two months Johnson-Perry Company must meet the demands provided in Table 1 for their Yummy brand and Wholesome brand sandwich patties. These demands must be met on time Max Monthly Total Production 12,000,000 During each month, at most 12 million patties total can be produced. Both Yummy and Wholesome patties can be held in inventory at a cost of $0.05 each per month in a cold storage facility Storage Cost per Unit 0.05 TABLE 2 Table 2 shows the cost per pound of raw material used to produce sandwich patties. Table 3 shows the pounds of raw material required to produce a single patty of each type. Meat and grain gruel can be used only in the month it was purchased. Cost per pound of raw materials Month 1 Cost per lb $0.10 Month 2 Cost per lb $0.14 0.18 $0.03 Dark Meat Light Meat Grain Gruel $0.02 As shown in Table 4, each Yummy patty produced contains 20 grams of fat and each Wholesome patty contains 8 grams of fat. Each month, the combination of all patties produced by the company must average no more than 13 grams of fat for regulatory reasons. IABLE3h Raw material required per patty (ibs) Dark Meat Light Meat Grain Gruel Yummy Wholesome 1.00 0.00 0.50 0.00 0.50 1.00 Develop a linear model and properly optimize it with Solver to minimize the total cost of producing and storing Yummy and Wholesome sandwich patties. Non-integer solutions are fine - Do not use any integer constraints. TABLE 4 Fat (g) per Patty Yummy Wholesome 20 Max Avg Fat (g) of Patties Produced per Mont 13

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts