Question: please help me understand these 5 problems with the work and answers provided:) 1. A computer production facility has a daily demand rate of 6

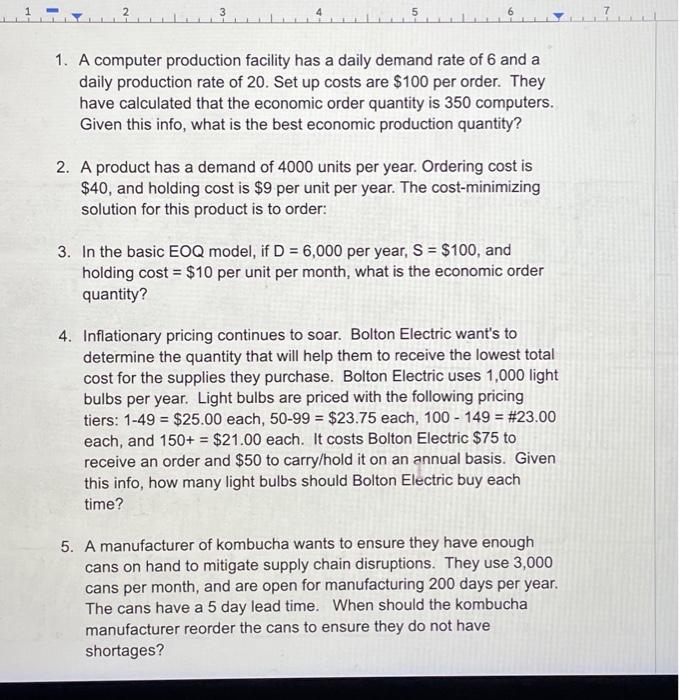

1. A computer production facility has a daily demand rate of 6 and a daily production rate of 20 . Set up costs are $100 per order. They have calculated that the economic order quantity is 350 computers. Given this info, what is the best economic production quantity? 2. A product has a demand of 4000 units per year. Ordering cost is $40, and holding cost is $9 per unit per year. The cost-minimizing solution for this product is to order: 3. In the basic EOQ model, if D=6,000 per year, S=$100, and holding cost =$10 per unit per month, what is the economic order quantity? 4. Inflationary pricing continues to soar. Bolton Electric want's to determine the quantity that will help them to receive the lowest total cost for the supplies they purchase. Bolton Electric uses 1,000 light bulbs per year. Light bulbs are priced with the following pricing tiers: 149=$25.00 each, 5099=$23.75 each, 100149=#23.00 each, and 150+=$21.00 each. It costs Bolton Electric $75 to receive an order and $50 to carry/hold it on an annual basis. Given this info, how many light bulbs should Bolton Electric buy each time? 5. A manufacturer of kombucha wants to ensure they have enough cans on hand to mitigate supply chain disruptions. They use 3,000 cans per month, and are open for manufacturing 200 days per year. The cans have a 5 day lead time. When should the kombucha manufacturer reorder the cans to ensure they do not have shortages

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts