Question: please help me understand what I did wrong here, and what I should input in cells to make answer right. using excel om software ..

please help me understand what I did wrong here, and what I should input in cells to make answer right. using excel om software

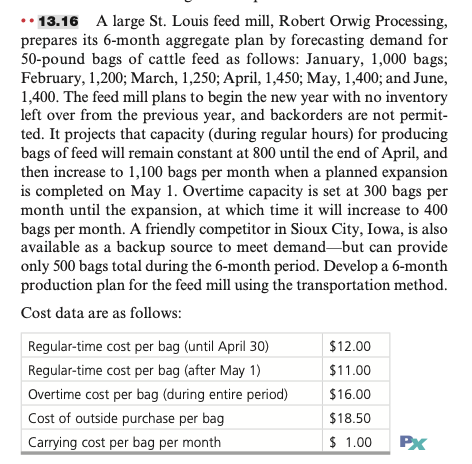

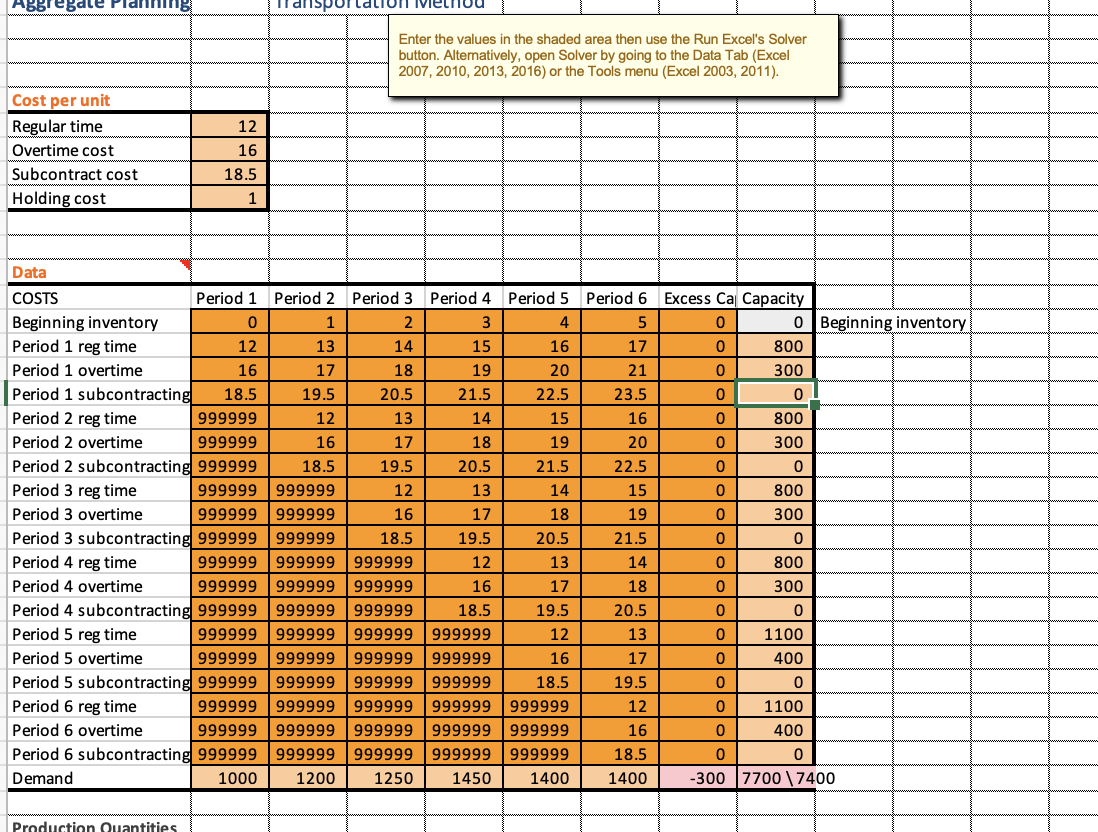

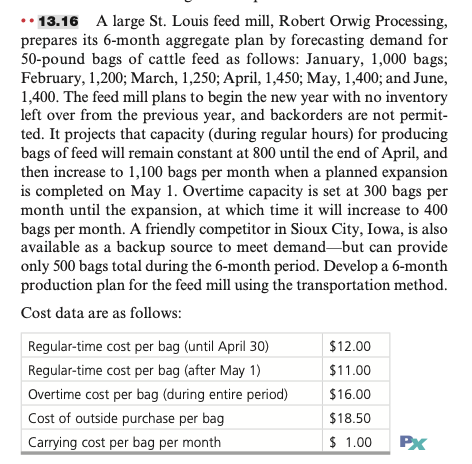

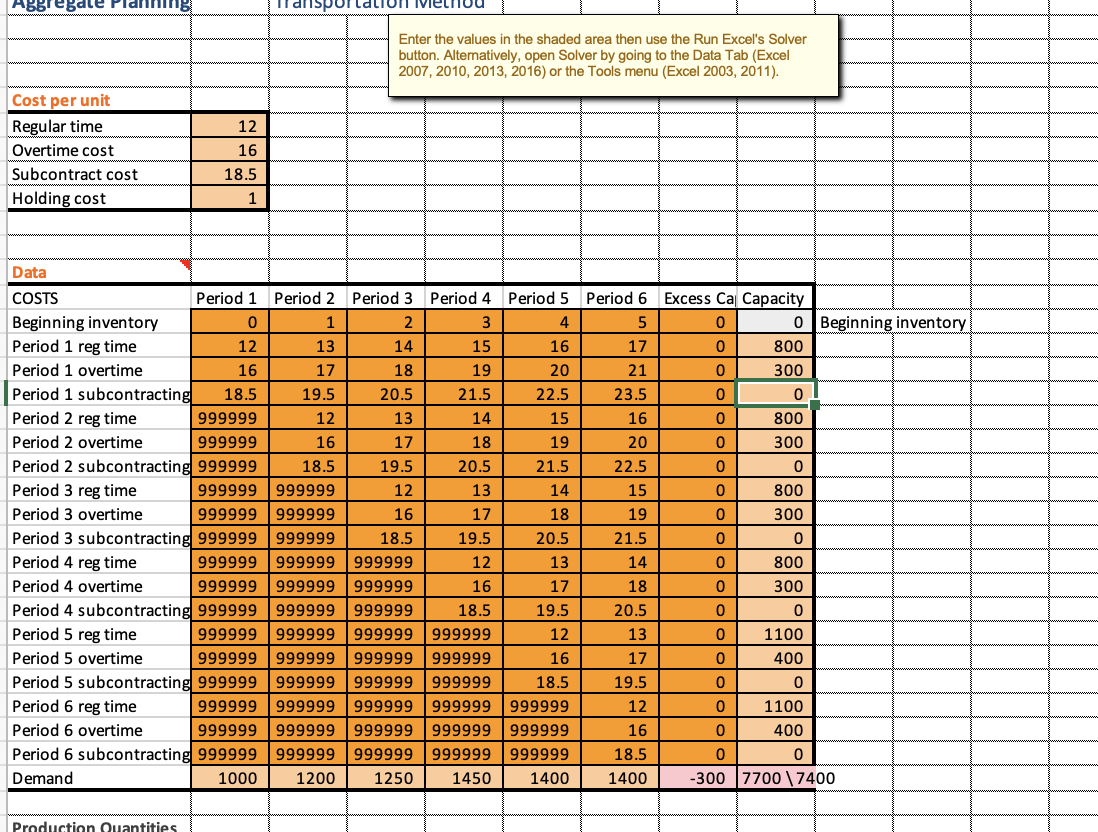

.. 13.16 A large St. Louis feed mill, Robert Orwig Processing, prepares its 6-month aggregate plan by forecasting demand for 50-pound bags of cattle feed as follows: January, 1,000 bags; February, 1,200; March, 1,250; April, 1,450; May, 1,400; and June, 1,400. The feed mill plans to begin the new year with no inventory left over from the previous year, and backorders are not permit- ted. It projects that capacity (during regular hours) for producing bags of feed will remain constant at 800 until the end of April, and then increase to 1,100 bags per month when a planned expansion is completed on May 1. Overtime capacity is set at 300 bags per month until the expansion, at which time it will increase to 400 bags per month. A friendly competitor in Sioux City, Iowa, is also available as a backup source to meet demandbut can provide only 500 bags total during the 6-month period. Develop a 6-month production plan for the feed mill using the transportation method. Cost data are as follows: Regular-time cost per bag (until April 30) $12.00 Regular-time cost per bag (after May 1) $11.00 Overtime cost per bag (during entire period) $16.00 Cost of outside purchase per bag $18.50 Carrying cost per bag per month $ 1.00 PX ABBreBace Pi Enter the values in the shaded area then use the Run Excel's Solver button. Alternatively, open Solver by going to the Data Tab (Excel 2007, 2010, 2013, 2016) or the Tools menu (Excel 2003, 2011). Cost per unit Regular time Overtime cost Subcontract cost Holding cost 12 16 18.5 1 16 Data COSTS Period 1 Period 2 Period 3 Period 4 Period 5 Period 6 Excess Cal Capacity Beginning inventory 0 1 2 3 4 5 0 Beginning inventory Period 1 reg time 12 13 14 15 16 17 800 Period 1 overtime 16 17 18 19 20 21 300 Period 1 subcontracting 18.5 19.5 20.5 21.5 22.5 23.5 0 0 Period 2 reg time 999999 12 13 14 15 16 0 800 Period 2 overtime 999999 16 17 18 19 20 0 300 Period 2 subcontracting 999999 18.5 19.5 20.5 21.5 22.5 0 0 Period 3 reg time 999999999999 12 13 14 15 0 800 Period 3 overtime 999999999999 16 17 18 19 0 300 Period 3 subcontracting 999999999999 18.5 19.5 20.5 21.5 0 0 Period 4 reg time 999999999999999999 12 13 14 0 800 Period 4 overtime 999999999999999999 16 17 18 0 300 Period 4 subcontracting 999999999999999999 18.5 19.5 20.5 0 0 Period 5 reg time 999999999999999999999999 12 13 0 1100 Period 5 overtime 999999999999999999999999 16 17 0 400 Period 5 subcontracting 999999999999999999999999 18.5 19.5 0 0 Period 6 reg time 999999999999999999 999999 999999 12 0 1100 Period 6 overtime 999999999999999999999999999999 16 0 400 Period 6 subcontracting 999999999999 999999 999999 999999 18.5 0 0 Demand 1000 1200 1250 1450 1400 1400 -300 7700 7400 11 1119 Production Quantities