Question: Please help me with this question~ 4. Resource Spending Approach: Assume the decisions to make pool shades and trellises are considered to be a short-term

Please help me with this question~

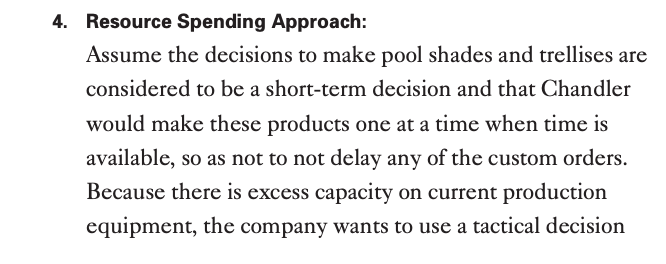

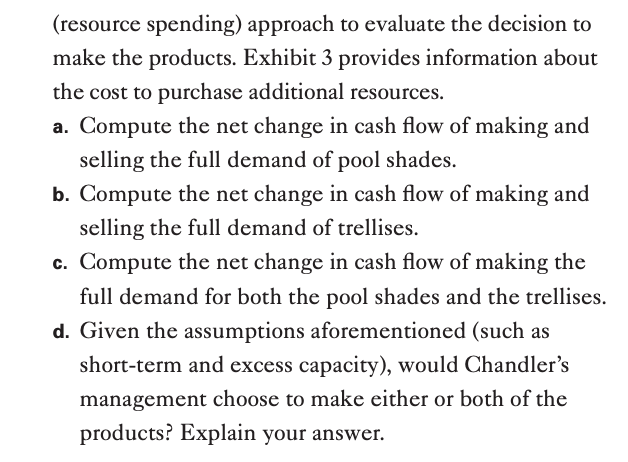

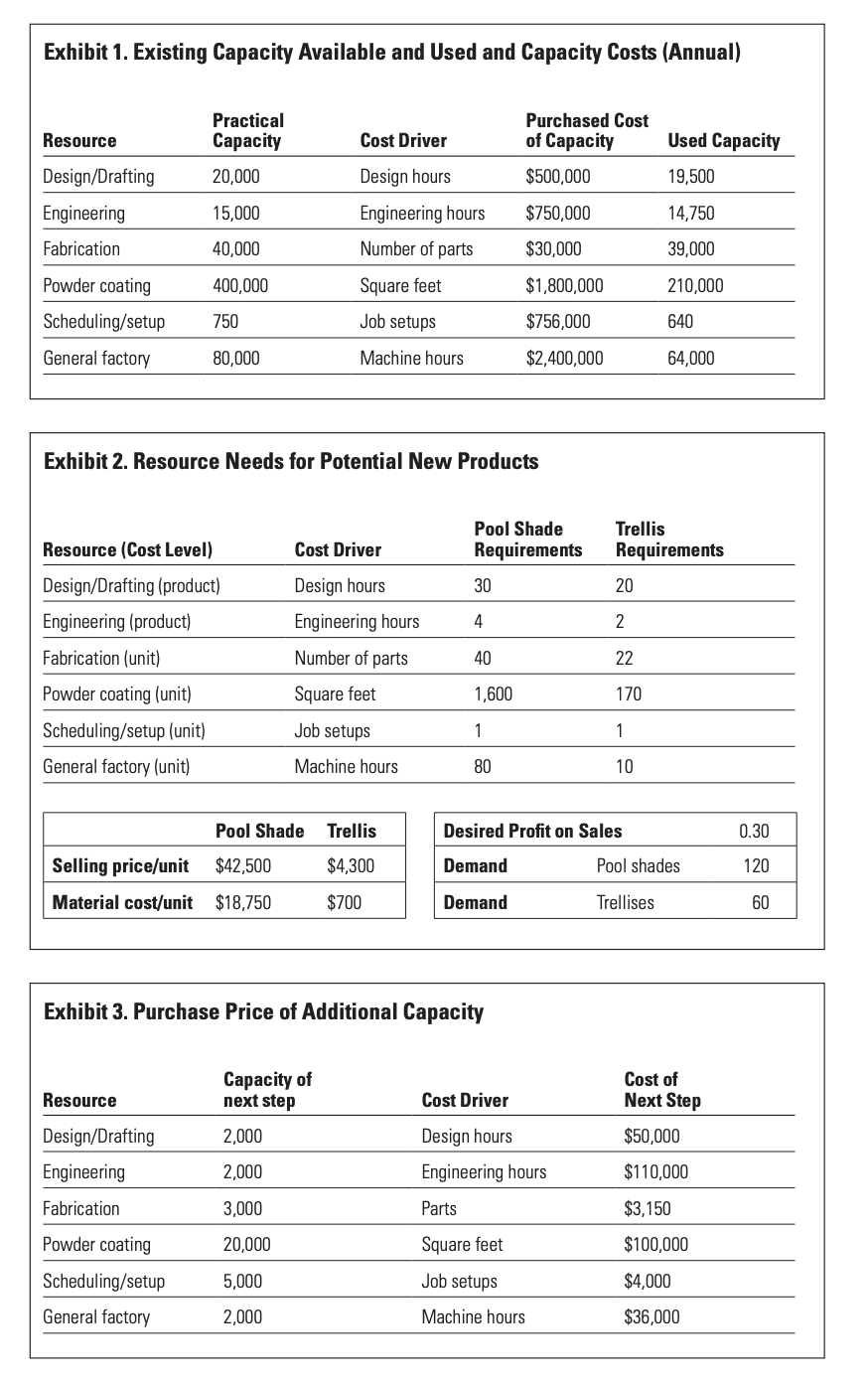

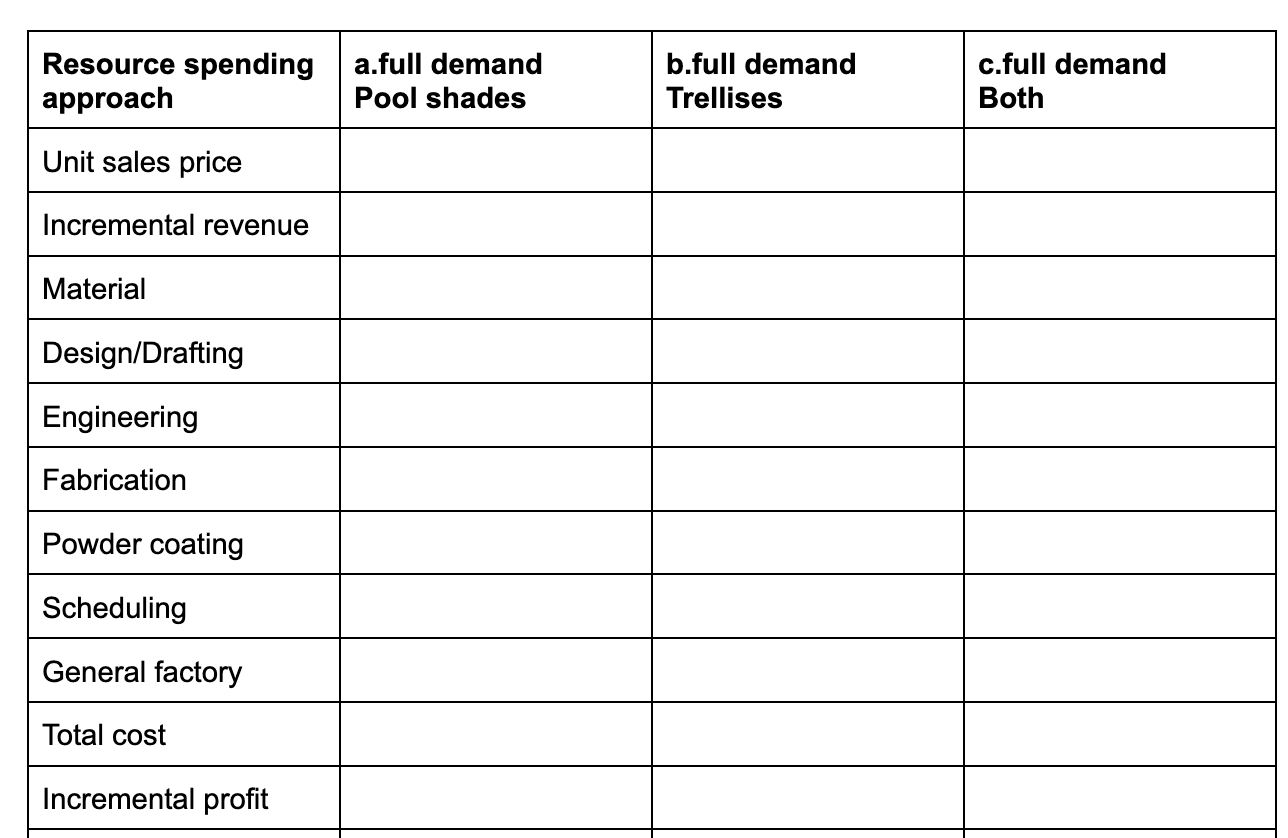

4. Resource Spending Approach: Assume the decisions to make pool shades and trellises are considered to be a short-term decision and that Chandler would make these products one at a time when time is available, so as not to not delay any of the custom orders. Because there is excess capacity on current production equipment, the company wants to use a tactical decision (resource spending) approach to evaluate the decision to make the products. Exhibit 3 provides information about the cost to purchase additional resources. a. Compute the net change in cash flow of making and selling the full demand of pool shades. b. Compute the net change in cash flow of making and selling the full demand of trellises. c. Compute the net change in cash flow of making the full demand for both the pool shades and the trellises. d. Given the assumptions aforementioned (such as short-term and excess capacity), would Chandler's management choose to make either or both of the products? Explain your answer. Exhibit 1. Existing Capacity Available and Used and Capacity Costs (Annual) Practical Capacity Purchased Cost of Capacity Resource Cost Driver Used Capacity Design/Drafting 20,000 Design hours $500,000 19,500 Engineering 15,000 Engineering hours $750,000 14,750 Fabrication 40,000 Number of parts $30,000 39,000 Powder coating 400,000 Square feet $1,800,000 210,000 Scheduling/setup 750 Job setups $756,000 640 General factory 80,000 Machine hours $2,400,000 64,000 Exhibit 2. Resource Needs for Potential New Products Pool Shade Requirements Trellis Requirements Resource (Cost Level) Cost Driver Design/Drafting (product) Design hours 30 20 Engineering (product) Engineering hours 4 2 Fabrication (unit) Number of parts 40 22 Powder coating (unit) Square feet 1,600 170 Scheduling/setup (unit) Job setups 1 1 General factory (unit) Machine hours 80 10 Pool Shade Trellis Desired Profit on Sales Selling price/unit $42,500 $4,300 Demand Material cost/unit $18,750 $700 Demand Exhibit 3. Purchase Price of Additional Capacity Capacity of next step Resource Cost Driver Design/Drafting 2,000 Design hours Engineering 2,000 Engineering hours Fabrication 3,000 Parts Powder coating 20,000 Square feet Scheduling/setup 5,000 Job setups General factory 2,000 Machine hours Pool shades Trellises Cost of Next Step $50,000 $110,000 $3,150 $100,000 $4,000 $36,000 0.30 120 60 Resource spending approach Unit sales price Incremental revenue Material Design/Drafting Engineering Fabrication Powder coating Scheduling General factory Total cost Incremental profit a.full demand Pool shades b.full demand Trellises c.full demand Both 4. Resource Spending Approach: Assume the decisions to make pool shades and trellises are considered to be a short-term decision and that Chandler would make these products one at a time when time is available, so as not to not delay any of the custom orders. Because there is excess capacity on current production equipment, the company wants to use a tactical decision (resource spending) approach to evaluate the decision to make the products. Exhibit 3 provides information about the cost to purchase additional resources. a. Compute the net change in cash flow of making and selling the full demand of pool shades. b. Compute the net change in cash flow of making and selling the full demand of trellises. c. Compute the net change in cash flow of making the full demand for both the pool shades and the trellises. d. Given the assumptions aforementioned (such as short-term and excess capacity), would Chandler's management choose to make either or both of the products? Explain your answer. Exhibit 1. Existing Capacity Available and Used and Capacity Costs (Annual) Practical Capacity Purchased Cost of Capacity Resource Cost Driver Used Capacity Design/Drafting 20,000 Design hours $500,000 19,500 Engineering 15,000 Engineering hours $750,000 14,750 Fabrication 40,000 Number of parts $30,000 39,000 Powder coating 400,000 Square feet $1,800,000 210,000 Scheduling/setup 750 Job setups $756,000 640 General factory 80,000 Machine hours $2,400,000 64,000 Exhibit 2. Resource Needs for Potential New Products Pool Shade Requirements Trellis Requirements Resource (Cost Level) Cost Driver Design/Drafting (product) Design hours 30 20 Engineering (product) Engineering hours 4 2 Fabrication (unit) Number of parts 40 22 Powder coating (unit) Square feet 1,600 170 Scheduling/setup (unit) Job setups 1 1 General factory (unit) Machine hours 80 10 Pool Shade Trellis Desired Profit on Sales Selling price/unit $42,500 $4,300 Demand Material cost/unit $18,750 $700 Demand Exhibit 3. Purchase Price of Additional Capacity Capacity of next step Resource Cost Driver Design/Drafting 2,000 Design hours Engineering 2,000 Engineering hours Fabrication 3,000 Parts Powder coating 20,000 Square feet Scheduling/setup 5,000 Job setups General factory 2,000 Machine hours Pool shades Trellises Cost of Next Step $50,000 $110,000 $3,150 $100,000 $4,000 $36,000 0.30 120 60 Resource spending approach Unit sales price Incremental revenue Material Design/Drafting Engineering Fabrication Powder coating Scheduling General factory Total cost Incremental profit a.full demand Pool shades b.full demand Trellises c.full demand Both

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts