Question: Please help me with this question! Essendon Ltd makes and sells two products. Alpha and Beta Case study 1 Essendon Ltd makes and sells two

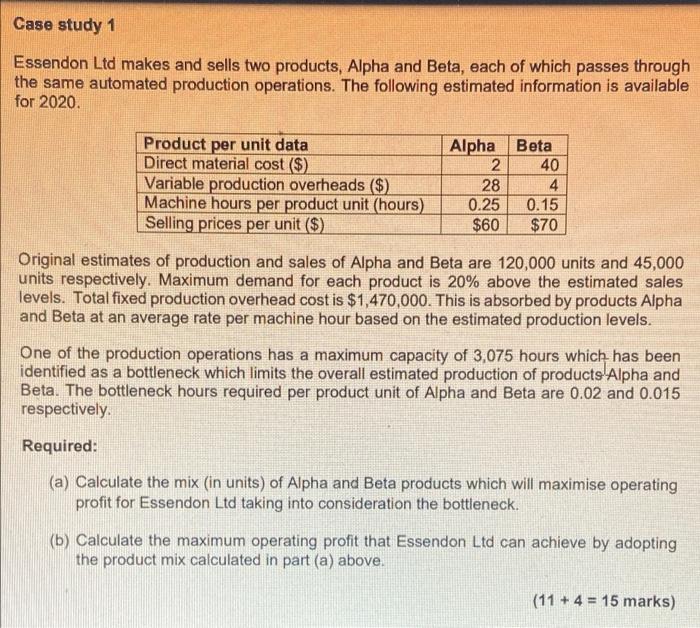

Case study 1 Essendon Ltd makes and sells two products, Alpha and Beta, each of which passes through the same automated production operations. The following estimated information is available for 2020. Product per unit data Direct material cost ($) Variable production overheads ($) Machine hours per product unit (hours) Selling prices per unit ($). Alpha 2 28 0.25 $60 Beta 40 4 0.15 $70 Original estimates of production and sales of Alpha and Beta are 120,000 units and 45,000 units respectively. Maximum demand for each product is 20% above the estimated sales levels. Total fixed production overhead cost is $1,470,000. This is absorbed by products Alpha and Beta at an average rate per machine hour based on the estimated production levels. One of the production operations has a maximum capacity of 3,075 hours which has been identified as a bottleneck which limits the overall estimated production of products Alpha and Beta. The bottleneck hours required per product unit of Alpha and Beta are 0.02 and 0.015 respectively Required: (a) Calculate the mix (in units) of Alpha and Beta products which will maximise operating profit for Essendon Ltd taking into consideration the bottleneck. (b) Calculate the maximum operating profit that Essendon Ltd can achieve by adopting the product mix calculated in part (a) above. (11 + 4 = 15 marks)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts