Question: please help solve a & b. thank you! :) End item P is composed of three subassemblies: K,L and W. K is assembled using 3Gs

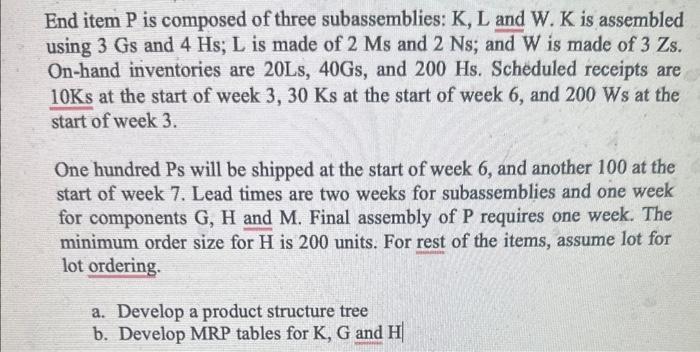

End item P is composed of three subassemblies: K,L and W. K is assembled using 3Gs and 4Hs; L is made of 2Ms and 2Ns; and W is made of 3Zs. On-hand inventories are 20Ls,40Gs, and 200Hs. Scheduled receipts are 10Ks at the start of week 3,30Ks at the start of week 6 , and 200Ws at the start of week 3. One hundred Ps will be shipped at the start of week 6, and another 100 at the start of week 7. Lead times are two weeks for subassemblies and one week for components G,H and M. Final assembly of P requires one week. The minimum order size for H is 200 units. For rest of the items, assume lot for lot ordering. a. Develop a product structure tree b. Develop MRP tables for K,G and H

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts